The Last Paradigm Is Production Reporting

This is the continuation of the transcript of a Webinar hosted by InetSoft on the topic of "Applying Business Intelligence to Manufacturing." The speaker is Mark Flaherty, CMO at InetSoft.

Then finally the last paradigm is what we call production reporting. We email you something. Its reporting and dashboards, but it doesn’t have to be something that you go and request. It could be something that shows up for you automatically. One of the ways that we use it at our company is we look at forecasts, and we get an automatic delivery of what everybody’s forecast is.

We see how they are doing according to their plan, and as a result we all know exactly what's going on without even doing any effort. Sometimes these things overlap. You start off with the canned report, but then you realize you want to find something else, so you got to an ad hoc reporting wizard.

You determine what you want to look for, manipulate the information and then you can publish that as a new dashboard. Now everyday you get that information just showing up, and that can be very helpful to people who need more and more information.

And I’d like to point out that this is only talking about people who are internal or business users, internal to your company right now, but one of the best facts about all of these very simple ways of receiving information, whether it is production reporting or interactive dashboards, is that external users find them very easy, too.

When you talk about somebody like a retailer who is trying to help their suppliers know what needed to go to them because of certain kinds of promotions, you can’t force your suppliers to learn a new BI tool. You can’t train them on these visual analytical applications. So being able to have the external customers be able to see oh, here’s this report, and this is what our distribution partner is going to need from me, that’s a tremendous benefit to those suppliers. It’s a tremendous benefit to the relationship between the two companies which is win-win for both the manufacturer and the retailer as well and any distributors that are involved in between.

How a Taxidermy Supply Shop Uses StyleBI for Production Reporting

WildForm Supplies, a niche retailer providing materials and equipment for taxidermists, adopted the open source StyleBI platform to streamline production reporting. Prior to implementation, the company relied on manual spreadsheets and disparate software to track inventory usage, custom order fulfillment, and workshop output. This approach was time-consuming, prone to errors, and limited management’s ability to quickly analyze trends or identify bottlenecks in the production and assembly of kits and supplies.

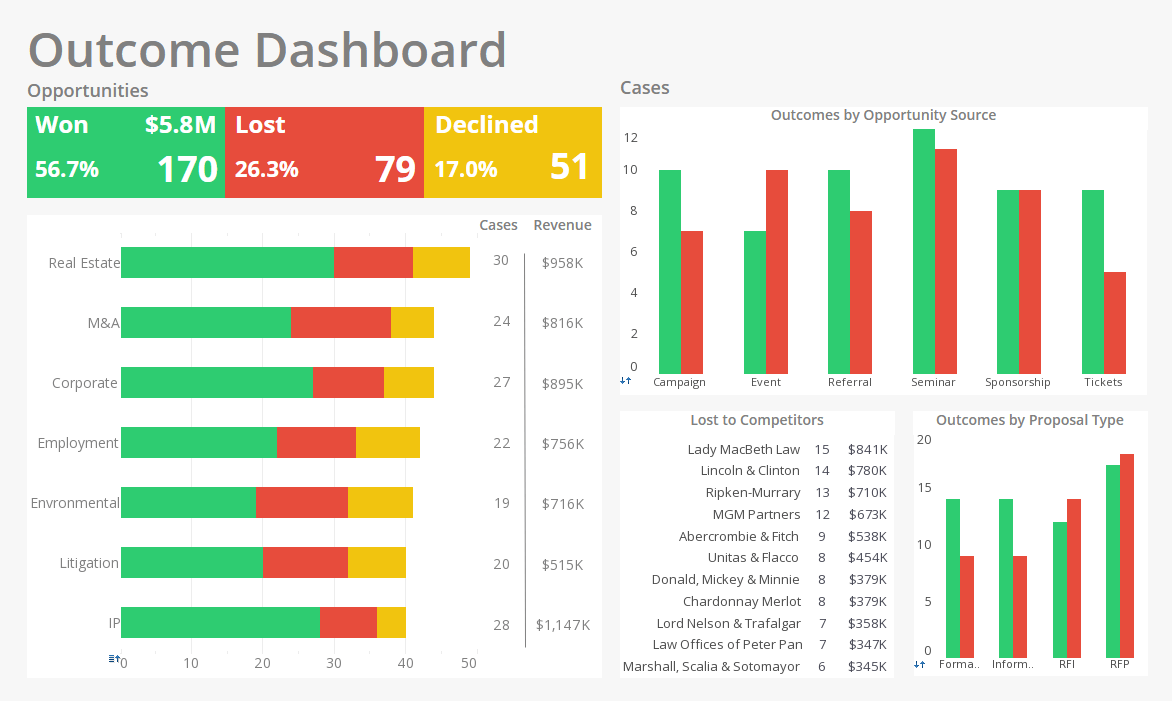

StyleBI allowed WildForm to integrate data from inventory systems, workshop logs, and sales platforms into a single reporting environment. Managers could create dashboards to monitor stock levels, track the consumption of specialized chemicals and tools, and forecast the materials required for upcoming custom orders. By visualizing the flow of materials through the workshop, production teams could identify delays or inefficiencies and adjust staffing or workflow schedules accordingly, improving turnaround time for customers.

The interactive features of StyleBI enabled supervisors to drill down into specific product lines, view real-time usage of inventory, and analyze patterns in custom kit assembly. For example, the platform highlighted which taxidermy forms or specialty adhesives were consistently overstocked or underutilized, allowing the company to optimize purchasing and reduce waste. Custom alerts and parameterized reports also ensured that managers received immediate notifications when critical inventory thresholds were crossed, preventing delays in fulfilling orders.

Staff adoption was accelerated by the self-service nature of StyleBI. Workshop supervisors and production staff could generate ad hoc reports and visualizations without relying on IT, allowing them to experiment with different performance metrics and identify operational improvements. This democratization of data enhanced collaboration across the workshop and the back-office, enabling teams to proactively address production challenges and maintain high levels of accuracy and efficiency in kit assembly.

Overall, using StyleBI transformed WildForm Supplies’ approach to production reporting. The company gained a real-time, accurate view of its operations, reduced waste, optimized inventory levels, and improved order fulfillment times. By leveraging open source BI, WildForm was able to maintain a cost-effective, scalable solution while turning production data into actionable insights that support both operational excellence and customer satisfaction in a highly specialized retail market.