Performance Management Best Practices

This is the transcript of an in-person customer seminar hosted by InetSoft on the topic of "Performance Management Best Practices." The speaker is Christopher Wren, Principal Consultant at TFI Consulting.

Today we're talking about performance management best practices. Organizations tend to follow similar patterns when it comes to performance management. They implement a performance management program, and it becomes structured into people’s daily routines. Then after some time people tend to get complacent and stop using those performance management tools.

So the question before us today is how do we move beyond that? How do we keep using these business management tools? There are lots of different things that I could share with you today, but I thought the best way to start will be to share with you are what I call the six fatal mistakes in performance management. I think this is a very important conversation because if you are going to build a sustainable model of performance management, it is very best, in my opinion, that you know where you’re failing. You need to be able to identify where the traps are, and if you see yourself falling into one of these traps, you can avoid it.

So that's what I'm going to talk to you about today. Are there any bowlers here today? Does any body bowl? I used to be a competitive bowler. Do you believe that? I love bowling. But if you go to bowling alleys, you know what bowling alleys are made of? They are made of wood. So if you go to bowling lanes where they are not up keeping the lanes, where they’re not regularly maintaining them, regularly polishing them, regularly providing essential care and maintenance of them, do you know what happens to those lanes?

Because people keep throwing their balls on them, they get ruts, they get ruts and in times those ruts turn into grooves, and folks, it doesn’t matter once the lanes had gotten rutted how good of a bowler you are, if you throw your ball on its rut, guess what? It stays in the rut, and it goes wherever that rut takes it. Why am I telling you this?

Is performance management new? Is this concept new? No, folks. It has been around for a long, long time, hasn't it? We’ve just changed the name. Back in the 60s it was planning program budgeting. What was it in the 70s? Managing by objectives. In the 80s, I know you all remember this one, total quality management, TQM.

Folks, all we've done is changed the name, right. The idea of data driven decision making is not new. So this concept has been around for a long time, and I think just like bowling alleys, if we don’t constantly care and maintain them, this thing that we’re calling performance management, a performance initiative, gets ruts. And what happens when you get ruts? It doesn’t matter how good you are, if you hit them, the balls going to follow them. So what I want to talk to you about today is what I call the six fatal mistakes, the six ruts that we get into. Here’s a good quote I came across: “When you start with an honest and diligent effort to determine the truth of a situation, the right decision often become self-evident.” And even if the right decision doesn’t become self-evident, you absolutely cannot make a serious good decision without first confronting the brutal facts.

Okay. Why am I telling you this? Every organization, everyone, hits this crossroads where the rules have changed. Something is fundamentally changing. It could be customer expectations. It could be the economy. It could be technology. Something has changed the rules. The organization has survived, and in fact, thrives on this change. Once you say hang on a minute, how does this affect us in our reality?

What are the brutal facts that we've got to face in order to survive and thrive on this change? Why am I telling you this? I think your organization may be at a crossroads, the pace, the rate, the scale of change in today’s work life is at an unprecedented level. That’s not my opinion. That’s well documented. Do you agree with that? It is, folks. We are at crossroads whether your in government or industry, you’re at a crossroads. I think what will define us a successful organization is what we do with this crossroad, whether or not we face these brutal facts and ask ourselves, what do we have to change?

Cryogenic Equipment Manufacturer Switching from SimpleKPI to StyleBI for Performance Management

In the realm of industrial manufacturing, cryogenic equipment manufacturers operate in one of the more specialized and obscure industries. Their work involves designing and producing storage tanks, pipelines, and refrigeration systems that handle extremely low-temperature substances such as liquid nitrogen, liquid oxygen, and liquefied natural gas. For decades, these companies have quietly played a critical role in fields ranging from medical research to aerospace and energy. Yet, like businesses in more mainstream sectors, cryogenic equipment manufacturers also face the universal challenge of measuring performance effectively. When one mid-sized cryogenic firm relied on SimpleKPI for tracking metrics, it initially seemed like the right fit. But as operations expanded, the company realized it needed a more robust performance management tool—leading to its eventual switch to StyleBI.

At first, SimpleKPI provided the company with a straightforward way to monitor key indicators such as production volume, delivery timelines, and safety compliance. The platform’s simplicity was attractive: dashboards were easy to set up, and team members could access visual reports without extensive training. For a niche manufacturer that wanted to move away from static spreadsheets, SimpleKPI represented a step forward. However, the limitations quickly surfaced. The system could handle basic tracking but struggled with the complexities of cryogenic manufacturing, where multiple data sources—from engineering design systems to supply chain logs—needed to be integrated. As a result, performance insights were fragmented, and the leadership team often lacked a unified view of operations.

One of the most pressing issues was data integration. Cryogenic equipment manufacturing requires close coordination between design engineers, production staff, safety officers, and logistics teams. Each department relied on different software, from CAD systems to inventory management platforms. SimpleKPI lacked the capacity to seamlessly combine these sources, forcing employees to manually import and update data on a regular basis. This not only consumed time but also introduced errors, undermining confidence in the dashboards. StyleBI’s data mashup capabilities solved this pain point by enabling real-time integration from disparate systems, ensuring that the dashboards reflected accurate and comprehensive performance metrics without manual intervention.

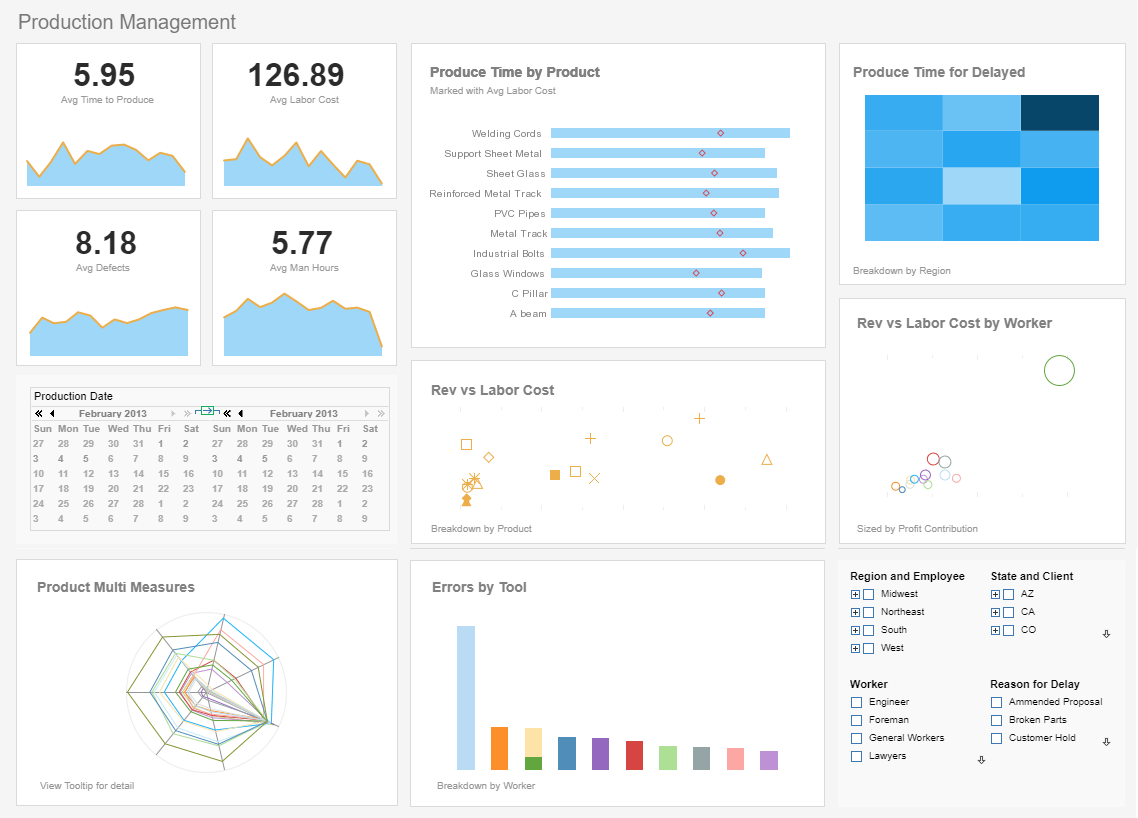

Another critical factor was the need for more advanced analytics. While SimpleKPI provided static visualizations and straightforward trend charts, it did not offer the depth of analysis required for strategic decision-making. The cryogenic manufacturer needed to forecast demand for liquid gas storage tanks, analyze defect rates across different product lines, and monitor the performance of suppliers who provided specialized materials. With StyleBI, the company gained access to multidimensional analysis, predictive modeling, and drill-down capabilities. Executives could now explore why delays were occurring in a particular product line or identify correlations between raw material quality and long-term equipment performance. These insights were far beyond what SimpleKPI could deliver.

StyleBI also addressed a long-standing challenge around role-based access and customized reporting. In the cryogenics sector, safety and compliance data must be tightly controlled due to the risks of working with extreme temperatures and volatile substances. With SimpleKPI, access controls were basic, leaving the IT team struggling to configure permissions for different user groups. StyleBI, by contrast, offered granular control, allowing safety officers, production managers, and executives to each view dashboards tailored to their responsibilities. This not only protected sensitive information but also improved productivity, since each user only saw what was relevant to their work.

The transition also brought major improvements to performance management at the strategic level. Before, leadership meetings often involved debating the accuracy of data and reconciling figures pulled from different systems. With StyleBI, the firm could establish a single source of truth. Dashboards showed up-to-date metrics across the entire value chain—from procurement to engineering to delivery—enabling more confident and data-driven decision-making. For example, the leadership team could monitor how well production goals aligned with customer delivery deadlines, track the impact of new safety protocols, and measure financial outcomes like profit margins per product line. These insights allowed the company to adjust strategies more quickly, avoiding costly delays or resource misallocations.

Another advantage came from StyleBI’s scalability and white-labeling options. The cryogenic manufacturer often worked with large international clients who demanded regular performance updates on project progress, equipment testing, and compliance certification. With SimpleKPI, reports for these clients had to be prepared manually and exported into PDF files. StyleBI allowed the company to create secure, branded dashboards that clients could access directly online. This transparency strengthened client relationships, as customers could monitor their projects in real time rather than waiting for periodic reports. For a business operating in such a technically demanding field, this added credibility and differentiated the firm from competitors still reliant on outdated reporting practices.

Financially, the move also proved advantageous. SimpleKPI’s pricing was reasonable for small-scale use, but as the company expanded, the limited functionality made it harder to justify the costs. StyleBI offered more value by combining performance management, data integration, and advanced analytics in one platform. The reduction in manual data handling saved hundreds of staff hours annually, which translated into tangible cost savings. Moreover, the ability to identify bottlenecks and inefficiencies in the production process improved throughput and reduced waste, directly boosting profitability.

Internally, the switch boosted employee engagement and accountability. Workers on the factory floor could see dashboards tracking safety incidents, production efficiency, and quality scores, which encouraged a culture of continuous improvement. Engineers appreciated being able to tie design decisions to production outcomes, while executives valued the clarity in financial and operational reporting. The visibility StyleBI provided helped align all departments around shared performance goals, reducing silos and fostering collaboration.