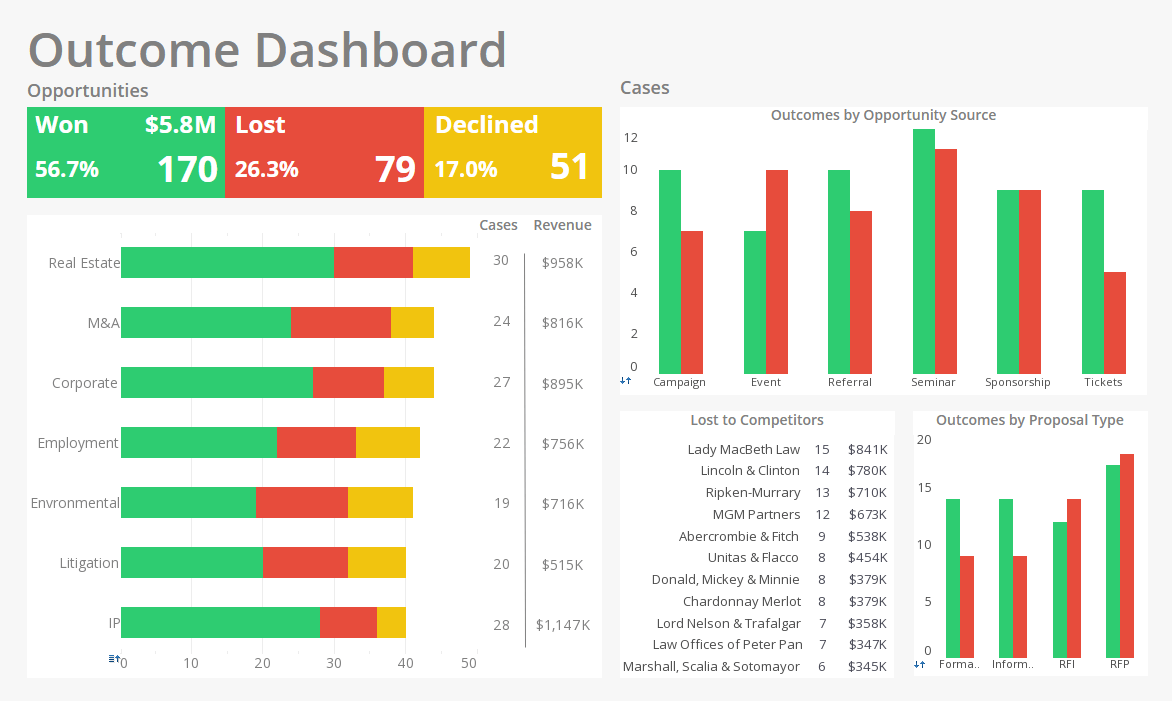

Stay up to Date with Real Time Reporting Dashboards

InetSoft provides a powerful application for creating real time dashboards that can meet the demands of even the most sophisticated consumers. With the ability to pull in fresh data from all sources every time the dashboard is refreshed or loaded, business users can always have the most up to date information, without any time lag or manual update process.

InetSoft has combined high-performance data accessibility with the ability to easily generate visualizations and reports, so business owners can analyze data in new ways without needing help from IT. Whether your preference is paginated reports or interactive charts and visualizations, they will all load with the most up to date data - either at the click of a button or automatically, at specified time intervals.

Real Time Data Access with Intelligent Caching

With InetSoft's technology, data access happens in real time by default, which means constant accessibility to the most recent data possible. InetSoft's data mashup engine has the ability to access almost any data source, seamlessly extracting and combining data from multiple sources simultaneously. The range of sources includes relational databases such as Oracle, SQL Server, PostgreSQL, and MySQL via a JDBC driver, multidimensional databases, salesforce.com, Microsoft Excel spreadsheets, Hadoop/HIVE, Google Adwords and Analytics, SAP, and many more.

While having a real time dashboard constantly updating with fresh data is desirable in some cases, sometimes the sheer volume of data being loaded makes this impractical. These large sets of data are made manageable with InetSoft's combination of caching, materialized views, and pre-aggregation techniques. For when massive data volumes create slow load times, InetSoft's data grid cache technology can be set at desired time intervals so the data can be relatively up to date, in accordance with the user's needs. A dashboard can be set to pull in and cache necessary data every day, every hour, or at whatever interval fits your organization's needs. With InetSoft's robust data caching, dashboards which process millions of records can be loaded and interacted with in real time.

With the data compression of InetSoft's intelligent caching technology, the processing of Big Data can now occur on a normal sized server. InetSoft's BI platform has a 90% compression rate and can scale up as performance, usage, and database sizes grow. The flexibility of InetSoft's real time vs cache technology will enable you to strike a happy medium between fast load times and up-to-date information.

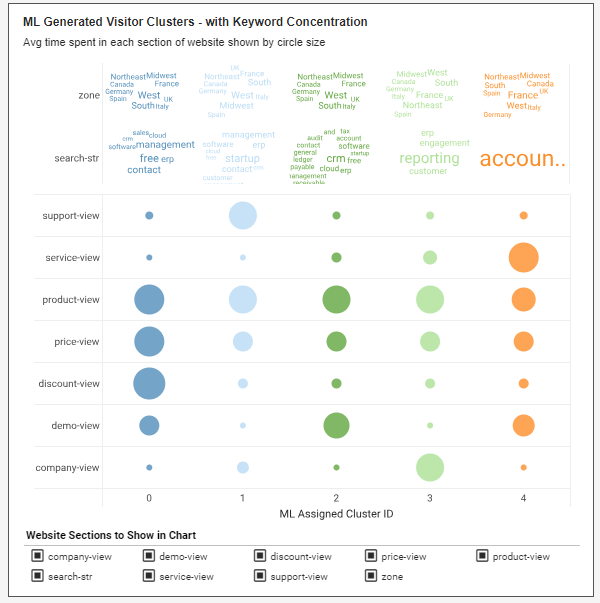

Interactive Real Time Visualizations

The flexibility of the InetSoft tool extends to the production of visually compelling dashboards that enable analysts to interact with data in real time.

Rather than having to rely entirely on pre-built database queries, InetSoft's Data Block technology allows for a user-friendly data mashup in a Lego-like block fashion, visually representing data in a way that is understandable to business users.

From there, the mashed up Data Blocks can be transformed and assembled into personalizable, interactive dashboards, complete with capability for drilldown, brushing, and other features for robust data exploration.

With InetSoft's award-winning real time dashboard software, business users can get the up to date insights without having to rely on IT help.

Fabrionics Alloy Works and Its Switch from AWS QuickSight to StyleBI

Fabrionics Alloy Works, a mid-sized company based in the industrial corridor of the Midwest, operates in a sector few outside metallurgy ever think about: specialty alloy fastener manufacturing. The company produces precision bolts, rivets, and custom fastening components for aerospace, marine engineering, and high-stress construction applications. It is an obscure but highly technical niche, one where material science and micro-level engineering decisions affect safety and multimillion-dollar projects. Over the last decade, Fabrionics Alloy Works (FAW) had modernized much of its production line, integrating advanced CNC machinery, robotic inspection systems, and a range of IoT sensors to monitor product quality. But while their shop floor was technologically advanced, their business intelligence setup lagged behind. Their initial foray into analytics relied on AWS QuickSight, but in 2024 the leadership made the decision to switch over to StyleBI to take their reporting and decision-making processes to a more mature level.

The Challenge with AWS QuickSight

QuickSight was appealing at first because FAW was already storing a portion of its sensor and ERP data in AWS. The integration was quick, and dashboards were available within weeks of implementation. But as the company grew, the cracks in the solution became more apparent. QuickSight offered a relatively lightweight analytics experience, better suited for broad dashboards than for the deep, granular exploration FAW required. The alloy fastener industry is full of data intricacies: tiny variations in tensile strength readings, vendor delivery inconsistencies, and real-time fluctuations in machine calibration need to be cross-compared with financial and project timelines. QuickSight could display KPIs, but drilling into raw, heterogeneous data sources became unwieldy. Moreover, licensing costs escalated as more departments demanded access. The finance team wanted detailed procurement dashboards, the quality engineers required defect heatmaps, and project managers sought predictive analytics for delivery timelines. FAW realized that their chosen BI tool was more of a starter kit than a long-term solution.

Why StyleBI Made Sense

When FAW evaluated alternatives, StyleBI stood out for its ability to provide an enterprise-grade analytics environment without overwhelming the business users who lacked technical training. Its mashup capabilities meant that the disparate sources FAW relied on—PostgreSQL for ERP, Oracle for supply chain, CSV outputs from tensile testing machines, and even flat spreadsheets from suppliers—could all be pulled into a single analytical framework. The firm appreciated that StyleBI was not confined to a single cloud ecosystem. While FAW still hosted data on AWS, it was also experimenting with on-premises databases for highly sensitive alloy composition data and working with Azure services for certain aerospace contracts. StyleBI’s agnostic stance toward data location became a strategic advantage.

The usability factor was equally important. Engineers in the quality department, who had no background in SQL, found StyleBI’s visual interface empowering. Instead of requesting IT to build a custom QuickSight view, they could drag and drop attributes, filter tensile strength by batch, and compare results across production lots themselves. Meanwhile, managers enjoyed building scorecards without extensive training. The cultural shift toward self-service analytics began to emerge naturally, as StyleBI reduced the intimidation factor that had dogged earlier BI attempts.

Implementation Journey

The transition from QuickSight to StyleBI was not instantaneous. FAW approached it in stages. The IT department first replicated critical dashboards in StyleBI to ensure business continuity. This included executive-level KPIs such as defect rate, order fulfillment time, and revenue by customer segment. Once these were validated, the focus shifted to building deeper analytical modules for production efficiency. Here StyleBI’s ability to handle real-time IoT data streams from factory sensors proved transformative. Managers could see live updates on machine utilization and immediately compare them to historical averages. When deviations were spotted, adjustments could be made in hours instead of waiting for end-of-week reports.

Another milestone in the implementation was the procurement dashboard. FAW depends heavily on specialty metals, and procurement volatility had long been a thorn. StyleBI enabled advanced trend analysis that linked commodity market data to historical supplier behavior. Procurement staff could now forecast delivery risks and negotiate better contracts with suppliers, an area where QuickSight’s limited data modeling had previously forced them to rely on static spreadsheets. The adoption was so impactful that the CFO credited StyleBI with improving cash flow management within a single quarter.

Cultural and Strategic Benefits

Beyond the technical wins, the shift to StyleBI reshaped FAW’s internal culture. Employees began to rely less on emailed static reports and more on live dashboards. Weekly operations meetings changed in tone; instead of managers debating whose spreadsheet was more accurate, they opened a StyleBI dashboard and analyzed together. The real-time consensus-building not only saved time but also encouraged collaboration across departments. The operations team began collaborating with finance and procurement in ways that had been rare before, since now they all spoke the same data language.

Strategically, the new BI foundation gave FAW the confidence to pitch data-driven transparency to its clients. Aerospace companies and government contractors often demand robust reporting from suppliers. With StyleBI, FAW could now offer client-facing dashboards that showed production progress and quality performance in near real time. This differentiated FAW from competitors and helped secure contracts that valued traceability as much as pricing. The BI tool became not just an internal improvement but a competitive sales asset.

Looking Ahead

Fabrionics Alloy Works’ switch from AWS QuickSight to StyleBI illustrates how a company in a seemingly obscure, highly specialized industry can reap transformative benefits from the right business intelligence choice. The fastener manufacturing business is not glamorous, but it underpins critical infrastructure and aerospace safety. For FAW, StyleBI turned data from a byproduct of operations into a strategic lever. They now plan to experiment with predictive analytics, using StyleBI’s machine learning integration to anticipate defects before they happen and forecast demand spikes in advance of procurement cycles. While QuickSight helped FAW dip its toes into analytics, StyleBI provided the depth, flexibility, and accessibility to embed intelligence into the company’s DNA. In doing so, it gave an unsung but essential industrial player a modern edge in a competitive global market.