A Reporting Tool for Business Analysts

Business analysts (BA) uphold the responsibility to interpret an organization's data, using the information to create solutions that will progress towards achieving business objectives.

InetSoft has developed StyleBI, an agile and robust BI software application that can manipulate massive amounts of raw data and convey it as detailed information in simple-to-manipulate visualizations.

The cost-efficient BI application provides a modern take on the conventional methods that would waste valuable time and delay the execution of solutions.

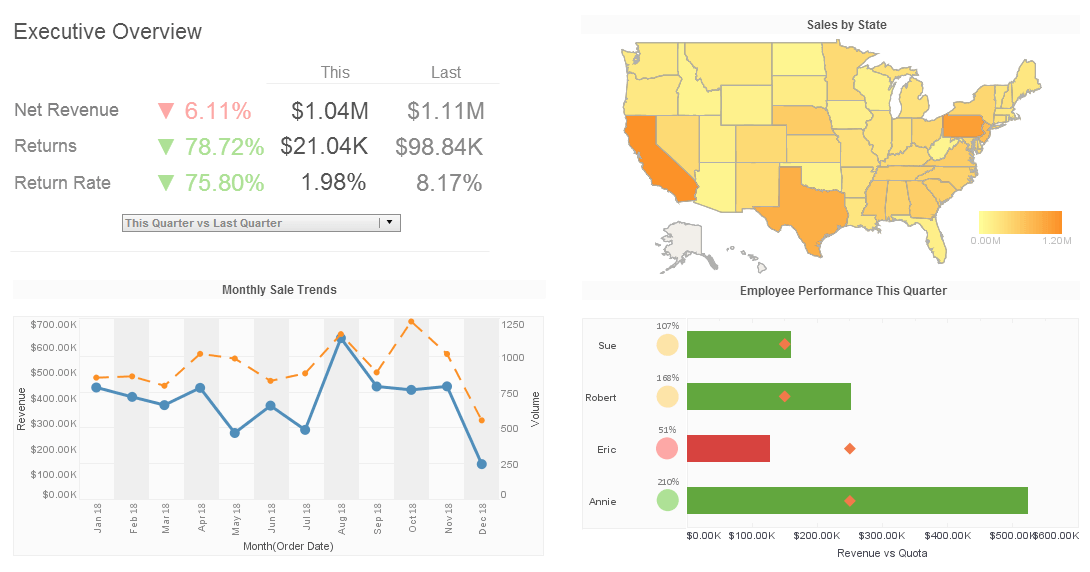

InetSoft's flagship BI empowers business analysts with productive dashboarding and visualization tools that facilitate finding reliable solutions. Business analysts have a maximum amount of self-service, need minimal IT intervention, and have absolute control of real-time data mashups and automated reporting capabilities.

Captivating Visualizations that Communicate for BA's

Since InetSoft's StyleBI is web-based, communicating the state of an organization to users in many locations is now easier than ever. The user friendly reporting engine enables the easy generation of pixel perfect reports that help define and monitor the metrics and status of an enterprise.

Anyone within the organization, from stakeholders to partners, have the ability to share and view real-time visualizations and business information. The software can also be accessed through any web browser and mobile device. With StyleBI implemented, reports and information can be shared with any locations that are given access.

Gain a Deeper Understanding with Data Mashup

InetSoft features a data mashup engine that organizes and consolidates massive amounts of data, which is structured to be manipulated within a single-view. StyleBI's easy drag-and-drop interface automatically writes queries for data exploration and precise reporting.

Strategies and assumptions about future actions can be answered with the software's capability to run statistical analyses on historical and real-time data.

Accessing InetSoft's Data Block technology through a drag-and-drop viewsheet, users can integrate their own data from spreadsheets and other diverse sources and create data mashups. This flexibility gives analysts complete freedom in running unique ad hoc reports, making predefined data models unnecessary.

Take advantage of InetSoft's easy, agile, and robust business intelligence for your BA needs.

How a Glassworks Switched from Jaspersoft to InetSoft for Reporting

In the niche world of handcrafted industrial glass production, few companies stand out like Egmont Glassworks, a mid-sized manufacturer located in northern Europe. Glassmaking as an industry is often overlooked compared to larger manufacturing sectors, yet it requires precision, safety, and operational oversight at every stage. Egmont Glassworks had long relied on Jaspersoft for its reporting needs, but as the company scaled up production and expanded into international markets, its management realized that Jaspersoft was no longer keeping pace with its evolving needs. After careful evaluation, the company decided to migrate its reporting tool to InetSoft, and the results have been transformative.

The Challenges with Jaspersoft

For years, Jaspersoft had served as Egmont Glassworks’ primary reporting system. The platform provided static reports that allowed managers to track furnace performance, energy consumption, defect rates, and shipping data. While functional, these reports lacked the interactivity and customization that modern manufacturing teams required. Production supervisors often complained that by the time they received weekly reports, the information was outdated. Adjustments to production schedules or raw material usage had to be made reactively instead of proactively.

Another issue was the difficulty in integrating Jaspersoft with newer data sources. Egmont had introduced IoT sensors into its furnaces and glass molding machines to monitor temperature fluctuations and detect micro-defects in real time. Jaspersoft required significant technical effort to connect to these streams, and when it did, the system often struggled with performance. The IT team found itself bogged down in report maintenance, spending more time troubleshooting than enabling innovation.

Why InetSoft Was Selected

InetSoft’s reporting and dashboarding capabilities aligned perfectly with Egmont’s requirements. The company was drawn to InetSoft’s data mashup engine, which allowed them to blend IoT sensor data, ERP data, and supply chain information into a single unified model. This was something Jaspersoft could not handle without heavy customization.

Furthermore, InetSoft’s web-based designer offered Egmont’s analysts the freedom to create interactive dashboards without needing extensive technical skills. Unlike Jaspersoft, which required heavy XML editing and configuration, InetSoft provided a drag-and-drop interface. This meant production managers themselves could design dashboards showing furnace temperature trends, defect heat maps, and delivery timelines without waiting for IT.

The CIO of Egmont summarized the shift: “We chose InetSoft not just because it was more powerful, but because it gave our operations team independence. They can now see what’s happening in the plant in real time, rather than waiting on a static PDF from last week.”

Implementation Process

The migration process was phased to minimize disruptions. Egmont began by running InetSoft in parallel with Jaspersoft, focusing first on replicating the most critical reports: furnace performance, batch defect rates, and shipping accuracy. Once the team verified that InetSoft could match and surpass the accuracy of Jaspersoft, they started rolling out more advanced dashboards.

One of the biggest wins came from the real-time monitoring dashboards. IoT sensors embedded in furnaces fed temperature and pressure data into InetSoft, where managers could see live trends. Alerts were configured to notify supervisors if a furnace began drifting from optimal operating ranges. With Jaspersoft, such visibility would have been impossible without waiting for a nightly batch process.

Impact on Operations

The shift to InetSoft produced noticeable operational improvements within months:

- Reduced Energy Waste: By visualizing live furnace performance, Egmont identified inefficiencies in energy usage. Adjustments saved the company nearly 12% on monthly energy costs.

- Lower Defect Rates: InetSoft dashboards displayed correlations between furnace conditions and defect occurrences. Supervisors used this information to fine-tune processes, reducing defect rates by 18% in the first quarter after implementation.

- Improved Supply Chain Visibility: By combining ERP and logistics data, InetSoft provided a consolidated view of raw material shipments and outbound deliveries. This visibility helped Egmont reduce late deliveries by 22%.

- Empowered Managers: Managers and team leads created their own dashboards without IT mediation. This self-service approach freed IT resources to focus on system improvements instead of repetitive reporting tasks.

Cultural Shift at Egmont Glassworks

The introduction of InetSoft also sparked a cultural shift. Before, reports were seen as a necessary but tedious part of operations. Now, dashboards became a central tool for decision-making. Daily production meetings included reviewing live InetSoft dashboards projected on large screens in the plant’s conference room. Workers on the shop floor gained more trust in management decisions because they could see the data behind them.

Additionally, InetSoft’s intuitive interface allowed younger employees, who were more tech-savvy, to experiment with creating custom reports. These efforts often revealed new insights that had been hidden in the data. For instance, one junior analyst built a dashboard correlating supplier lead times with defect rates, revealing that certain raw materials arriving late were linked to hurried production and higher breakage.

Comparing InetSoft and Jaspersoft

While Jaspersoft is well-regarded as an open-source reporting tool, it operates best when generating static, formatted reports. Egmont found this increasingly inadequate for the demands of modern glassmaking. InetSoft, on the other hand, emphasized real-time interactivity, mashup capabilities, and embedded analytics. The difference was not just technological but philosophical. Jaspersoft was about delivering documents; InetSoft was about empowering decisions.

Another comparison came down to maintenance. Jaspersoft required more coding and XML configuration to adjust reports, making even small changes cumbersome. InetSoft’s drag-and-drop design reduced reliance on IT and made iterative improvements easier. This agility proved essential in a manufacturing environment where conditions change daily.

Future Outlook

With InetSoft in place, Egmont Glassworks is now exploring advanced applications such as predictive analytics. The plan is to use InetSoft to integrate historical furnace performance data with weather forecasts, anticipating how external temperature and humidity affect production quality. Another initiative involves embedding InetSoft dashboards into customer portals, giving clients transparency into their orders and expected delivery dates.

Egmont’s leadership believes the investment will pay dividends for years to come, not only in operational savings but also in customer satisfaction and competitive positioning. In an industry where margins are thin and reliability is paramount, better reporting has become a strategic advantage.