Using InetSoft's Reporting Tools in a Data Warehousing Environment

Take your data warehousing capabilities to the next level with InetSoft's BI Solution. StyleBI enhances data utilization by employing a powerful data mashup engine, providing a convenient web-based platform, and offering efficient tools for creating compelling dashboards and reports.

StyleBI's simple interface eliminates the obstacle of IT training that standard data warehousing tools require. After a fast deployment, InetSoft's user-friendly BI software maximizes self-service with automated query requests and reporting capabilities.

InetSoft's robust data mashup engine can seamlessly integrate and handle vast amounts of disparate data to create a single source of information. The ability of users to massage data from data warehouses and store necessary data in-memory makes the traditional ETL process unnecessary, diminishing latency in the data warehouse.

Versatile Tools for Better Solutions

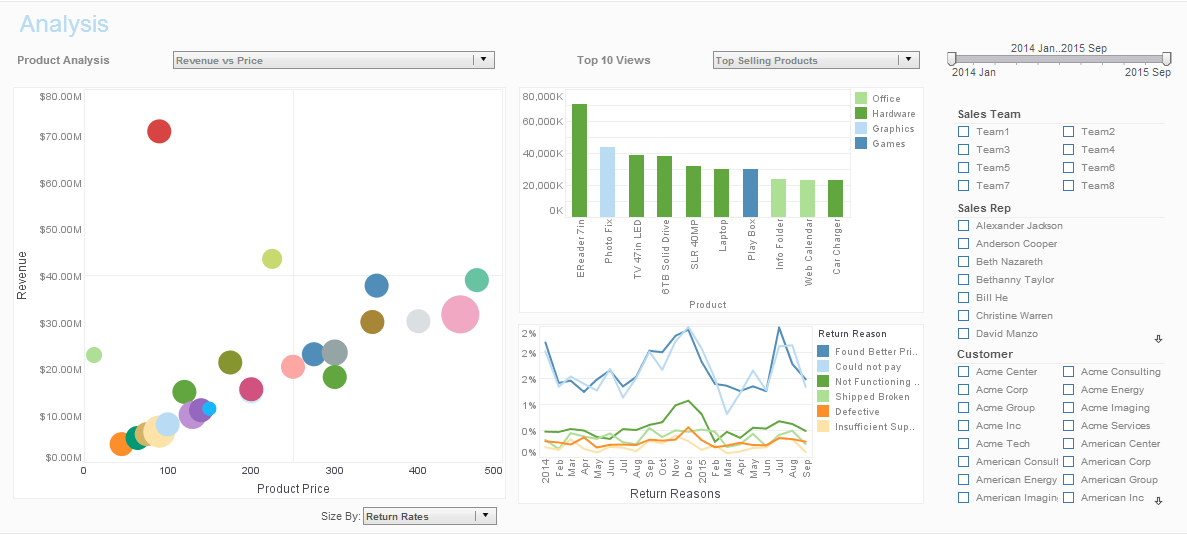

StyleBI's reporting and dashboarding tools can work with virtually any data source or operational database, so producing an analysis report or generating an interactive dashboard will present reliable and accurate information that reflects all accumulated knowledge.

The reporting engine tool grants users the rapid conversion of time-sensitive information into a publishable report format for easy sharing and distribution. Users will be able to easily deliver sophisticated and professional quality reports for effective presentations and publications.

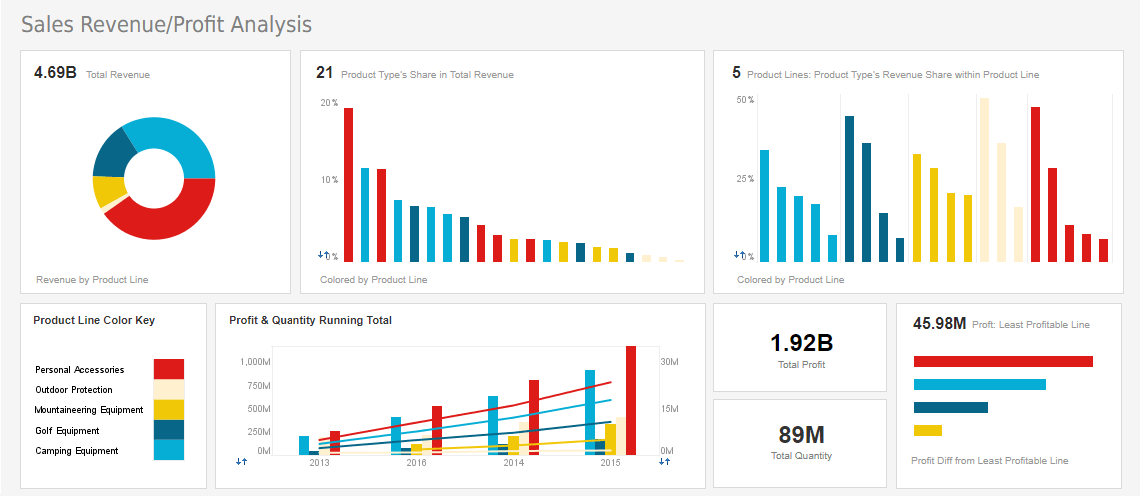

InetSoft's user viewsheet brings end-user functionality to the data warehousing environment, by enabling users to create interactive dashboards with a simple drag-and-drop interface. These dashboards give enterprises the ability to measure KPI's and perform data analysis visually, revealing new insights to non-technical users.

ElectroLumina Inc. Switches from Crystal Reports to InetSoft for Data Warehouse Reporting

ElectroLumina Inc., a leading manufacturer in the electroluminescent materials industry, recently made a strategic shift in its business intelligence tools, moving from Crystal Reports to InetSoft. The company specializes in producing high-quality electroluminescent films and panels used in specialty lighting applications, including aviation instrument backlights, automotive dashboards, and wearable technology. As the company expanded its product lines and increased production volumes, its legacy reporting system—Crystal Reports—began to show limitations in performance, flexibility, and integration with its growing data warehouse. The decision to adopt InetSoft was motivated by a need for more agile, interactive, and insightful reporting capabilities.

Challenges with Crystal Reports

Crystal Reports had been a reliable reporting solution for ElectroLumina for many years. It provided static, formatted reports that allowed management to monitor production quantities, defect rates, and inventory levels. However, as ElectroLumina scaled, several limitations became apparent. First, Crystal Reports required manual coding for complex reports, making the creation of new reports time-consuming and reliant on IT staff. The process of modifying reports to accommodate new KPIs or data sources was slow, reducing the company's agility in decision-making.

Another significant challenge was integration. ElectroLumina’s data warehouse contained multiple sources, including ERP data, quality control systems, and IoT sensor feeds from production lines. Crystal Reports struggled to efficiently connect to these diverse datasets, often requiring pre-processing or extraction of data before reporting. As a result, management often received insights that were several days old, making it difficult to respond promptly to production issues or market changes.

Additionally, Crystal Reports lacked interactive dashboards. While the static reports were sufficient for historical analysis, they offered little support for exploratory analysis or real-time monitoring. Users had to export reports to Excel or PDF for further manipulation, which introduced delays and potential errors. This limitation became increasingly problematic as ElectroLumina expanded into multiple global markets, where timely access to production and sales data was critical.

Why InetSoft Was Chosen

InetSoft’s Style Intelligence platform addressed many of the limitations the company faced with Crystal Reports. Its web-based dashboard designer and interactive reporting capabilities allowed users to create custom reports and visualizations without extensive IT involvement. This self-service approach empowered production managers, quality engineers, and sales analysts to access and analyze data directly from the data warehouse.

A key factor in selecting InetSoft was its ability to perform data mashups. ElectroLumina’s data warehouse contained diverse sources, from SQL-based ERP tables to sensor feeds and external supplier data. InetSoft’s data mashup engine allowed the company to combine these sources seamlessly, creating unified datasets for reporting. This eliminated the need for extensive pre-processing and reduced latency between data capture and insight generation.

The Chief Data Officer of ElectroLumina stated, “InetSoft transformed our approach to reporting. We can now generate insights in real time, blending multiple data sources into interactive dashboards that support decision-making at every level of the company.”

Implementation Process

The transition from Crystal Reports to InetSoft was carefully planned to minimize disruptions. ElectroLumina implemented a phased approach, starting with a parallel run of both systems. The initial phase focused on replicating critical reports, such as production throughput, defect rates, and inventory levels, to ensure data consistency. During this period, IT teams verified that InetSoft accurately reflected the data warehouse and validated the calculations used in existing Crystal Reports.

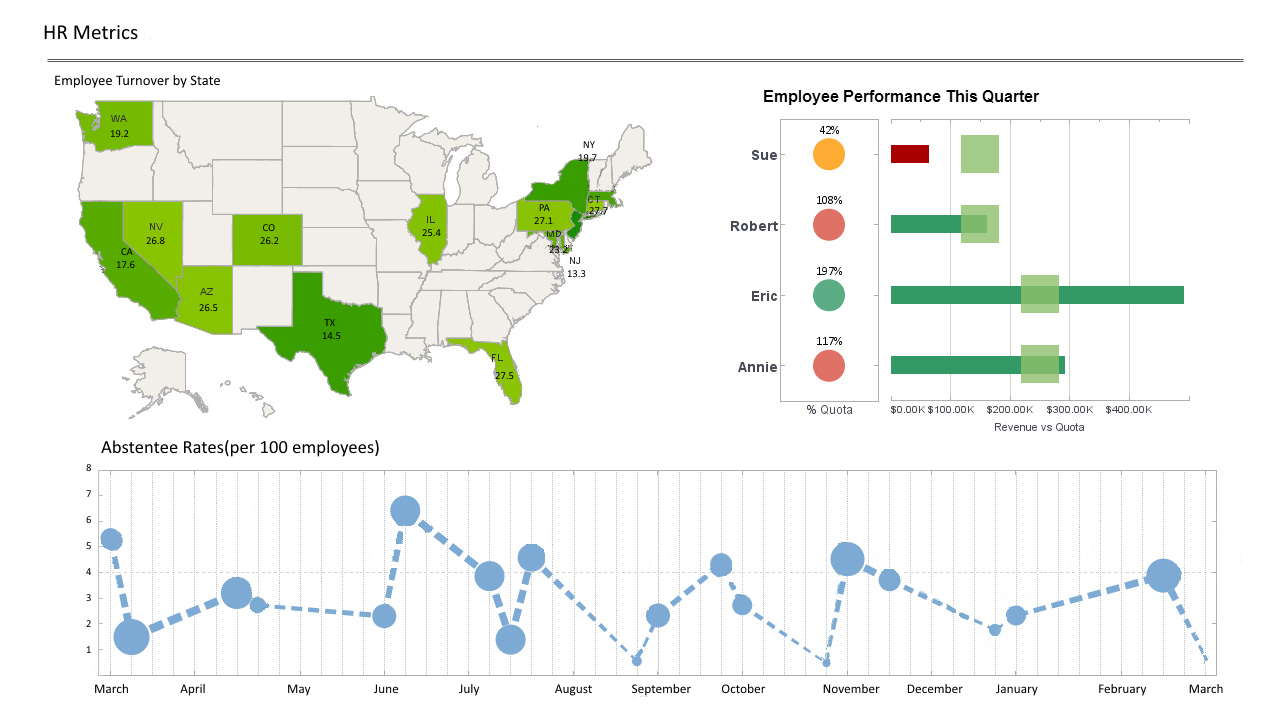

Following the successful validation of core reports, ElectroLumina moved on to developing advanced dashboards. These dashboards provided real-time monitoring of production lines, tracking key variables such as panel thickness consistency, phosphor uniformity, and machine operating temperatures. Interactive features, including drill-downs and dynamic filters, allowed users to explore data at different levels of granularity, enabling rapid identification of anomalies or process inefficiencies.

The IT team also leveraged InetSoft’s scheduling and automated distribution features. Reports and dashboards could be automatically delivered to stakeholders via email or embedded in internal portals, ensuring that relevant data reached the right people without manual intervention. This automation reduced the burden on IT staff and ensured that decision-makers had timely access to insights.

Operational Improvements

The switch to InetSoft led to significant operational improvements across ElectroLumina’s business. One immediate benefit was enhanced visibility into production efficiency. Managers could monitor real-time machine performance and identify bottlenecks before they caused delays. As a result, line downtime decreased, and production throughput increased by approximately 15% in the first quarter after implementation.

Quality control also benefited from the new system. By combining sensor data from production lines with historical defect records, engineers could quickly identify patterns and root causes of defects. This led to a 20% reduction in product defects within six months, improving customer satisfaction and reducing waste.

Inventory management became more responsive. Dashboards integrated ERP and warehouse data, allowing supply chain teams to track raw material levels and finished goods in real time. This visibility helped reduce stockouts and overstock situations, optimizing working capital and lowering storage costs.

User Empowerment and Cultural Shift

Beyond operational gains, InetSoft fostered a cultural shift within ElectroLumina. Employees at all levels were empowered to interact directly with data, explore trends, and create custom reports tailored to their responsibilities. Production supervisors, for example, developed dashboards that visualized shift performance metrics and machine utilization, enabling more informed operational decisions on the floor.

The ability to self-serve reports also encouraged a data-driven mindset. Teams began using dashboards not just for reporting but for planning and forecasting. Sales analysts could quickly correlate production capacity with customer demand, enabling more accurate order commitments and better allocation of resources across global markets.

Comparing InetSoft and Crystal Reports

The contrast between InetSoft and Crystal Reports is substantial. Crystal Reports excelled in generating static, formatted reports, but it lacked the flexibility, interactivity, and integration capabilities required by modern manufacturing. InetSoft, with its mashup engine, web-based designer, and interactive dashboards, provides a more agile platform that supports both operational and strategic decision-making.

Maintenance and iteration are also simpler with InetSoft. Adding new KPIs or integrating new data sources can be done through the web-based interface, reducing reliance on IT and speeding up the reporting cycle. This agility has allowed ElectroLumina to keep pace with production innovations, market expansions, and evolving analytical needs.

Future Outlook

With InetSoft in place, ElectroLumina is exploring advanced analytics initiatives. The company plans to leverage historical production and sensor data for predictive maintenance, anticipating equipment failures before they occur. Additionally, dashboards are being extended to supplier and customer portals, providing transparency into raw material availability, production status, and delivery timelines.

The flexibility of InetSoft also positions ElectroLumina to experiment with new product lines. Real-time analytics allow R&D teams to monitor small-scale production runs, quickly evaluating process changes and their impact on product quality. This data-driven approach accelerates innovation and reduces the risk associated with introducing new electroluminescent materials.

Lessons for Manufacturing Companies

ElectroLumina’s experience illustrates how modern reporting tools can drive efficiency, quality, and agility in manufacturing. Companies relying on legacy reporting systems may face delays in insight generation, limited integration options, and static reporting that does not support proactive decision-making. Transitioning to a platform like InetSoft allows organizations to consolidate data, provide interactive dashboards, and empower users across the business to act on insights in real time.

ElectroLumina’s leadership emphasizes that the move from Crystal Reports to InetSoft was not just a technical upgrade—it was a strategic enabler, transforming the company’s operational efficiency, decision-making speed, and data culture.