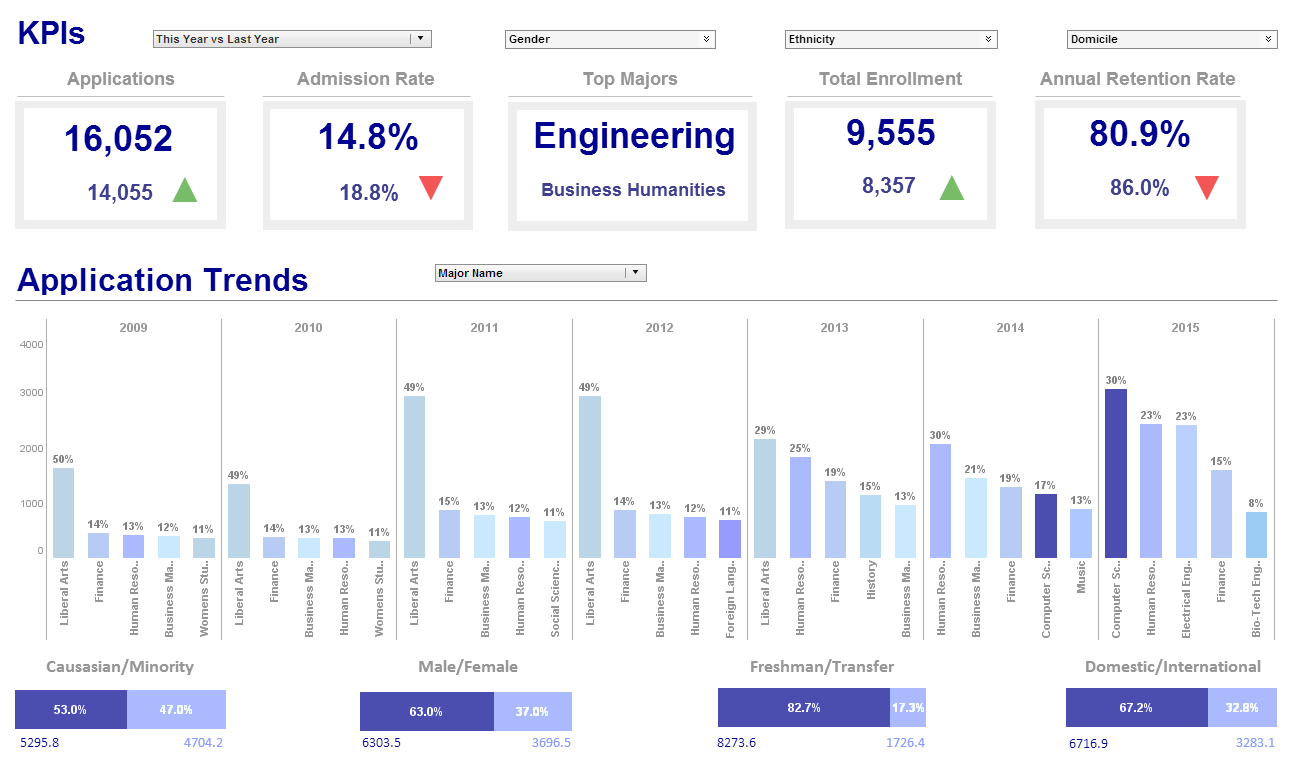

Data Reporting System

Whether you have customer data, manufacturing data, sales data, or any other type of data, you to make sense of and present it.

InetSoft makes this easy with StyleBI, a fully featured BI solution for your organization. Once deployed, it makes sorting and reporting your data easy.

Report Creation

StyleBI provides businesses with top of the line enterprise reporting through a 100% Web-based zero client application. Users can create ad hoc, interactive, or other kinds of reports simply through the use of an innovative drag-and-drop design.

Users can drag data from a large variety of different kinds of databases directly onto a WYSIWYG report designer to quickly create professional reports. Textual information can be added to any report through a familiar word processor-esque interface.

Utilizing the drag-and-drop interface, data can be placed into tables, freely positioned on the field, or charted by a library of over 30 different chart varieties. Users can then automate these reports to run of their own accord at specified times during the year.| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

Report Viewing

Once a report is created, it can be shared quickly and efficiently throughout an organization. StyleBI supports mobile reporting accessible from any Web-enabled device, including Android and Apple devices, as well as all popular Web browsers.

Report viewers can sort, hide, and filter data to find that which is relevant to their interests. Reports support full drilldown functionality to access another report or URL directly from the initial report.

Reports can be exported to Excel, PowerPoint, PDF, RTF-Word, CSV, PostScript, Text, SVG, and even email for ultimate flexibility.

Visualization-Driven Ad Hoc Reporting

Business users are looking for quick and easy ways to create new reports or visualizations of their data. Rather than the old model of giving time and resource consuming requests to database analysts, IT and business managers are looking for the kind of self-service functionality provided by StyleBI to meet the demands for ad hoc reports.

|

View the gallery of examples of dashboards and visualizations. |

Hydraulic Press Manufacturing Uses InetSoft's Data Reporting System

Hydraulic press manufacturers face a unique challenge: maintaining uptime while ensuring quality and cost control across high-value, heavy-duty machinery production lines. Integrating a modern data reporting system can transform operations, and InetSoft's StyleBI has proven to be a valuable tool for hydraulic press manufacturers aiming to enhance performance visibility and actionable insights. This article details how a mid-sized hydraulic press manufacturer leveraged InetSoft's StyleBI to monitor, analyze, and optimize their operational, quality, and financial performance using advanced dashboards and real-time analytics.

Challenges in Hydraulic Press Manufacturing

Before adopting StyleBI, the manufacturer faced:

- Manual data collection from PLCs, MES, and ERP systems causing delays and errors.

- Lack of real-time visibility into press cycle time efficiency and downtime reasons.

- Difficulty tracking preventive maintenance and parts usage patterns.

- Inconsistent quality monitoring across different press models and operators.

- Fragmented financial visibility, making cost-per-unit tracking difficult.

Implementing InetSoft's StyleBI

InetSoft's StyleBI was implemented across production, quality, and financial operations, connecting to data sources including SQL Server-based ERP, OPC UA-based machine data, and cloud-based CRM and financial systems. Using its data block architecture, the manufacturer created reusable data blocks for:

- Production metrics aggregation (cycle time, downtime, OEE).

- Quality monitoring (defect rates, scrap reasons, rework volumes).

- Maintenance KPIs (MTTR, MTBF, scheduled vs. unscheduled maintenance).

- Financial tracking (cost per unit, material usage, variance analysis).

StyleBI’s self-service capability allowed engineers, plant managers, and financial analysts to design customized dashboards while maintaining central governance for metric definitions and security.

Key KPIs Tracked with StyleBI

The manufacturer selected the following KPIs to align operational goals with actionable insights:

- Overall Equipment Effectiveness (OEE): Tracks the availability, performance, and quality across each hydraulic press.

- Cycle Time Efficiency: Compares planned vs. actual cycle times for each product type and press.

- Downtime Reasons: Categorizes downtime into mechanical, hydraulic, tooling, and operator delays.

- Scrap and Rework Rates: Tracks by machine, operator, and product line to identify patterns.

- Preventive Maintenance Compliance: Monitors adherence to maintenance schedules, reducing unplanned breakdowns.

- Cost Per Unit: Breaks down material, labor, energy, and overhead costs per press cycle.

- MTTR and MTBF: Tracks mean time to repair and mean time between failures for critical components.

- Order Fulfillment Time: Measures time from order to shipment, tracking delays tied to production inefficiencies.

Dashboards and Advanced Charting

InetSoft’s StyleBI enabled the manufacturer to build layered dashboards to provide actionable views for operators, supervisors, and executives:

1. Production Dashboard

- Heatmaps: Show presses with the highest downtime frequency and total downtime duration.

- Bullet Charts: Display OEE against monthly targets per press.

- Line Charts: Show cycle time trends over days and shifts.

- Gantt Charts: Display maintenance schedules and actual maintenance events.

2. Quality Dashboard

- Stacked Bar Charts: Display defect types per press and operator for the month.

- Scatter Plots: Analyze rework rates vs. cycle times across different models.

- Trend Lines: Show monthly scrap rates with control limits.

3. Financial Dashboard

- Stacked Area Charts: Visualize cost per unit by component (material, labor, energy).

- Waterfall Charts: Illustrate variance analysis between planned and actual production costs.

- Pivot Tables: Enable slicing cost data by product line, press, and order type.

Analytics for Continuous Improvement

InetSoft’s StyleBI advanced analytics enabled the manufacturer to move beyond passive monitoring. They used:

- Time Series Forecasting: Predictive analysis of maintenance needs based on usage and performance trends.

- Correlation Analysis: Determining how cycle times, temperature, and operator shifts impact defect rates.

- Root Cause Analysis: Interactive drill-down from high scrap rates into machine configurations and maintenance logs.

- What-If Simulations: Estimating OEE impacts when adjusting planned downtime schedules.

These capabilities facilitated Kaizen initiatives on the shop floor, allowing teams to reduce average cycle times by 8% while lowering scrap rates by 12% within six months of implementation.

Integrating with Existing Systems

Using InetSoft's REST API and connectors, StyleBI was integrated with the manufacturer’s existing MES and ERP systems without heavy customization. Data refresh rates were configured for near-real-time (every 5 minutes) on key production and maintenance data streams, while financial and quality data updated hourly. Role-based access control ensured that sensitive cost data remained secure while operators accessed production and quality dashboards directly from their HMI stations.

Benefits Realized

Key results achieved by using InetSoft’s StyleBI include:

- Reduction in unplanned downtime by 15% due to clearer visibility into downtime causes and maintenance compliance.

- 8% improvement in average cycle time efficiency, leading to higher throughput with the same machine capacity.

- 12% reduction in scrap rates due to better defect tracking and operator accountability.

- Improved maintenance scheduling through predictive analytics, reducing reactive repairs and costly delays.

- Streamlined cost reporting, enabling finance teams to quickly identify material cost overruns tied to specific presses or operators.

Future Plans with StyleBI

The manufacturer plans to further expand their StyleBI deployment by:

- Embedding dashboards within their supplier portal to share real-time demand and defect data with key suppliers.

- Integrating IoT sensor data for hydraulic pressure, temperature, and vibration monitoring for predictive maintenance models.

- Automating downtime alert notifications to maintenance teams via Slack and Microsoft Teams using StyleBI webhook capabilities.

- Building executive summary dashboards to align operations, quality, and financial metrics into a single real-time view.