Optimizing Tunnel Infrastructure Projects with InetSoft’s StyleBI: A Heavy Civil Contractor’s Journey

In the realm of heavy civil construction, data visibility and operational agility are critical. From managing multimillion-dollar budgets to tracking progress across geographically dispersed tunnel sites, firms must rely on modern information systems to maintain efficiency and accountability. This article explores how a tunnel-specialized heavy civil contractor—let's call them StrataCore Infra—leveraged InetSoft’s StyleBI, an open-source information reporting and dashboarding tool, to modernize their KPIs, improve project transparency, and empower technical teams with real-time insights.

Background: Complexity Beneath the Surface

StrataCore Infra operates across multiple continents and executes long-term, high-risk tunneling projects. Their projects often span:

- TBM (Tunnel Boring Machine) operations and maintenance

- Excavation progress monitoring

- Concrete lining installations

- Geological mapping and safety compliance

Historically, data was siloed in legacy systems, Excel reports, and PDF weekly summaries. Project managers spent countless hours reconciling budgets and schedules, while engineers lacked real-time access to equipment metrics. The firm needed a platform that was lightweight, customizable, and capable of integrating disparate data sources—enter StyleBI.

Implementation: Why StyleBI?

StyleBI stood out for several reasons:

- Open-source flexibility – Allowed StrataCore’s IT department to tailor data connectors and embed dashboards in internal portals.

- Java-based architecture – Compatible with StrataCore’s existing enterprise stack (Spring Boot microservices).

- HTML5 & SVG charts – Enabled crisp rendering on mobile devices used in the field.

- Modular visual elements – Perfect for creating interactive portlets across dashboards for TBM operators, geologists, and finance teams.

Dashboard Ecosystem: Purpose-Built for Operations

The IT team created four core dashboard portals:

- Operations Portal – Focused on daily TBM performance, crew assignments, and excavation progress.

- Project Controls Portal – Used by project managers to monitor budgets, change orders, and milestone timelines.

- Safety & Compliance Portal – Aggregated incident reports, training completions, and geological risk indices.

- Financial Insights Portal – Delivered executive-level KPIs on project burn rate, vendor costs, and ROI estimates.

Core KPIs Tracked Across Portals

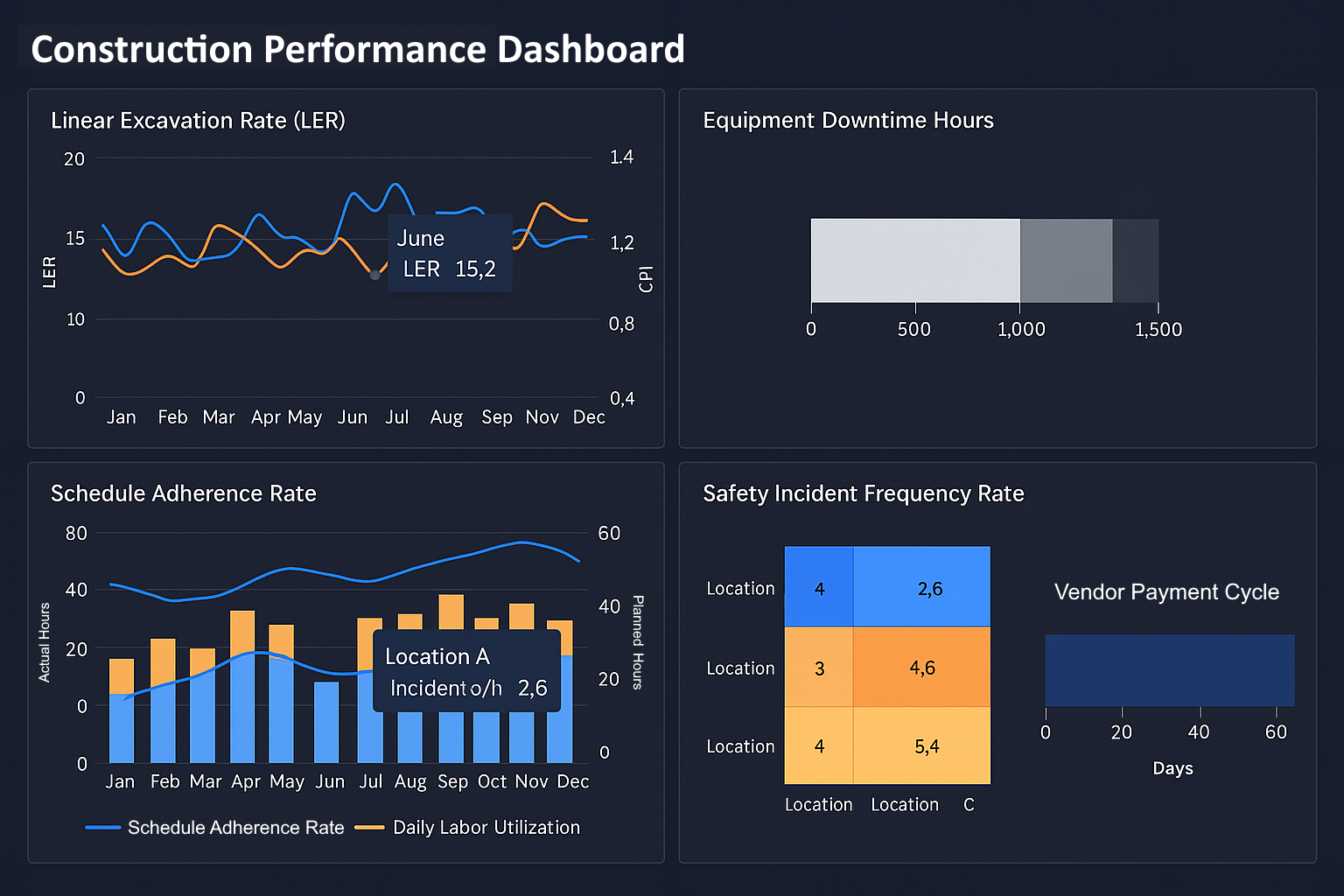

- Linear Excavation Rate (LER) – Measured in meters/day by TBM.

- Cost Performance Index (CPI) – Earned value vs. actual cost.

- Schedule Adherence Rate – % of activities completed as planned.

- Daily Labor Utilization – Tracked crew deployments vs. planned hours.

- Equipment Downtime Hours – Logged and categorized per machine type.

- Safety Incident Frequency Rate – Incidents per 100,000 labor hours.

- Vendor Payment Cycle – Avg. days to process and pay invoices.

1. Linear Excavation Rate (LER)

- Definition: The average number of meters excavated per day by a TBM or manual crew.

- Why it matters: Indicates drilling efficiency and progress versus schedule.

- Typical Visualization: Line charts with trend overlays; combined with rock hardness metrics for deeper insights.

2. Cost Performance Index (CPI)

- Definition: Earned Value / Actual Cost; a ratio used in earned value management.

- Why it matters: Measures budget efficiency. CPI > 1 means cost underrun; CPI < 1 means cost overrun.

- Chart Types: Dual-axis trend lines or bullet charts that compare cumulative actuals vs. forecasts.

3. Schedule Adherence Rate

- Definition: % of scheduled activities completed on time.

- Why it matters: Provides real-time schedule performance and flags delays.

- Visualizations: Gantt overlays, completion tickers, milestone heatmaps.

4. Daily Labor Utilization

- Definition: Ratio of actual crew hours worked vs. planned.

- Why it matters: Highlights crew deployment efficiency and over-/under-utilization risks.

- Charts: Stacked column charts by shift and crew type.

5. Equipment Downtime Hours

- Definition: Hours that key machinery like TBMs, ventilation systems, or pumps are non-operational.

- Why it matters: Impacts project continuity and cost. Root-cause analysis often follows high downtimes.

- Visualization: Pareto charts showing top causes; pie charts by equipment category.

6. Safety Incident Frequency Rate

- Definition: Incidents per 100,000 labor hours — a normalized safety metric.

- Why it matters: Safety compliance and risk prevention; critical for high-risk underground environments.

- Visuals: Heatmaps by location; hover tooltips detail type, time, and resolution.

7. Vendor Payment Cycle

- Definition: Average number of days taken to process and pay vendor invoices.

- Why it matters: Affects vendor relations and supply chain stability.

- Chart Types: Sankey diagrams for flow, histograms for distribution.

The Role of StyleBI in Managing These KPIs

- Cross-filtering: Drill from CPI down to activity or vendor level.

- Dynamic visuals: Real-time updates tied to ERP or IoT feeds.

- Custom alerts: Triggered when KPIs fall outside thresholds — like low LER or rising incident rates.

Chart Types and Visualizations

StyleBI’s flexible visual layer enabled dynamic filtering, drilldowns, and intuitive navigation. Among the most used components:

- Dual Axis Line Chart – Overlaid LER vs. CPI over time to find productivity bottlenecks.

- Heatmaps – Used in safety dashboards to visualize high-risk zones based on incident location.

- Bullet Charts – Ideal for executive summaries showing budget vs. forecasted spend.

- Stacked Column Charts – Displayed labor hour breakdowns across trades and shifts.

- Tree Maps – Helped procurement visualize vendor allocations by spend category.

- Interactive Timeline Charts – Used by geotechnical teams to visualize faults and bore path anomalies.

- Geospatial Overlay Widgets – Integrated with internal GIS tools to show tunneling alignment vs. terrain risks.

Reporting and Distribution

StyleBI supported ad-hoc and scheduled reports via HTML, Excel, and embedded iFrames. Some key workflows:

- Daily TBM Metrics Report – Automated emails to field teams showing prior 24-hour stats.

- Weekly Progress Summary – Sent to stakeholders with interactive graphs and milestone updates.

- Monthly Financial Digest – Shared with CFO showing cumulative CPI, forecasted overrun, and vendor performance charts.

Interactivity That Drives Action

By incorporating drilldowns and hover tooltips, dashboards moved from passive reports to actionable interfaces. For example:

- Hovering on LER data points showed shift-specific crew details and rock hardness ratings.

- Clicking on vendor bars opened payment history and delivery timelines.

- Selecting a zone on heatmaps triggered pop-ups with incident causes, OSHA notes, and links to training reports.

Lessons Learned

StrataCore’s IT department noted three important takeaways:

- Customization is key – StyleBI allowed for deep tailoring, but required strong developer ownership.

- User feedback drives adoption – Field teams helped shape which metrics were most useful, improving buy-in.

- Combine data sources early – Integrating ERP, GIS, and IoT feeds upfront made dashboard rollout smoother.