What Metrics Does a Quality Operations Analyst Use?

Keeping operations at a high standard is essential for success and guaranteeing client happiness. The efficiency and efficacy of numerous processes inside a company are closely monitored and improved by a Quality Operations Analyst. To do this, they use analytics and key performance indicators (KPIs) to evaluate performance, identify areas for development, and inform decision-making.

In order to improve operations and provide remarkable results, a Quality Operations Analyst employs 18 important KPIs and analytics, which we will discuss in this article.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

Customer Satisfaction (CSAT)

Any successful firm is built on the success of its customers. The Quality Operations Analyst can determine how effectively the company is fulfilling customers' expectations by measuring CSAT. This measure, which is often gathered via surveys or feedback forms, offers useful insights into client sentiment. To improve the general customer experience, the analyst may identify problems and potential improvement areas.

Net Promoter Score (NPS)

The Net Promoter Score (NPS) gauges customer loyalty and the chance that consumers would refer the business's goods or services to others. It is a crucial KPI for determining brand advocacy and consumer loyalty. The analyst may determine which areas of the company are generating good or negative feedback by segmenting NPS data, enabling them to take strategic measures in response.

First Contact Resolution (FCR)

FCR keeps track of the proportion of client complaints or questions that are answered within the first conversation with a customer service agent. Customer happiness is highly dependent on effective and efficient customer service, which is shown by a high FCR. By identifying training requirements, simplifying procedures, and offering assistance to frontline staff, the Quality Operations Analyst will concentrate on raising FCR rates.

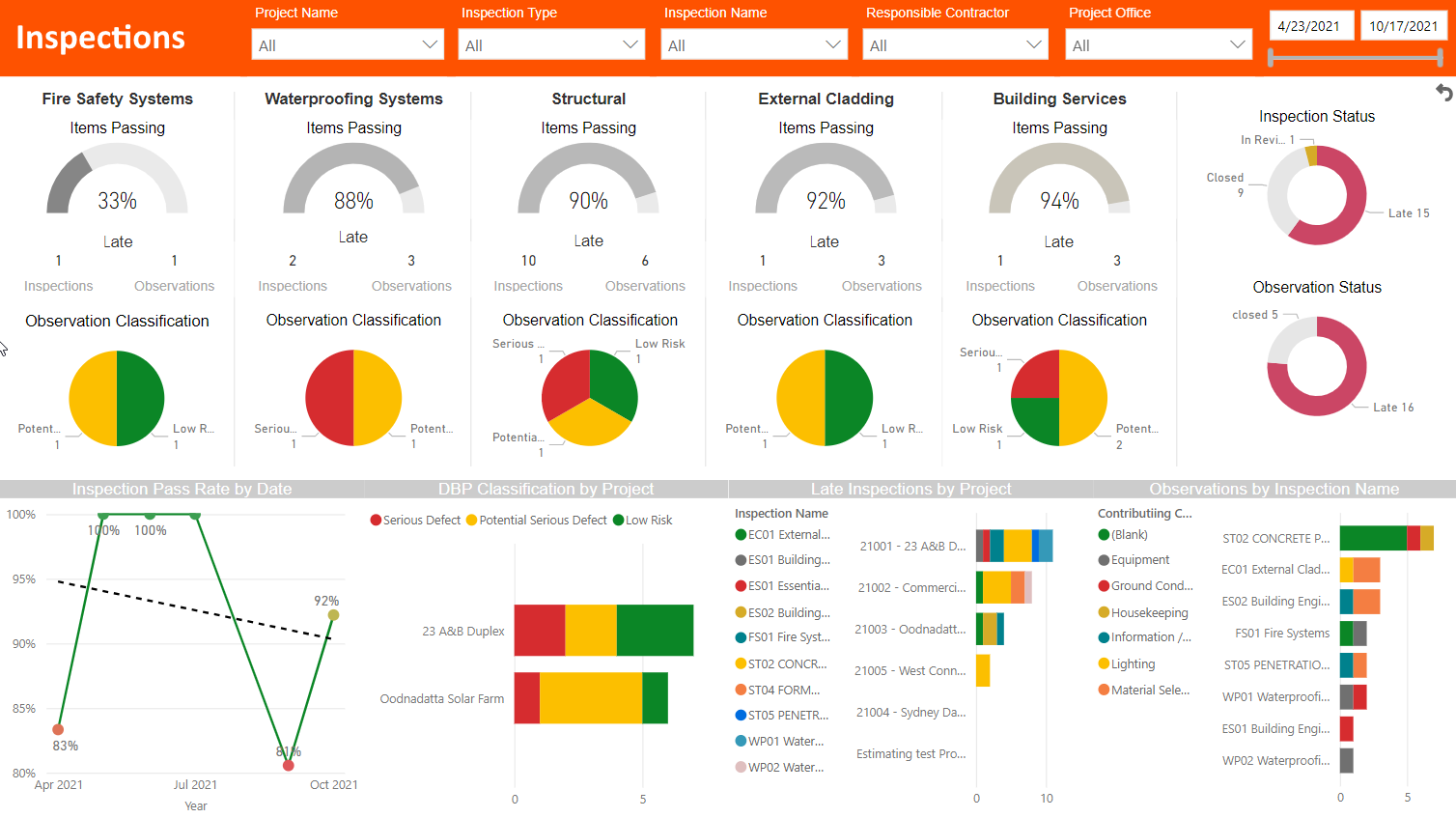

|

View the gallery of examples of dashboards and visualizations. |

Service Level Agreement (SLA) Compliance

In businesses focused on services, SLA is essential. It specifies the response and resolution times that the company agrees to provide for client questions or problems. To guarantee that service standards are regularly met or surpassed, the Quality Operations Analyst analyzes SLA compliance. If they aren't, they look into the underlying issues and suggest solutions.

Quality Assurance (QA) Score

Based on predetermined criteria and norms, the QA score assesses the quality of client interactions, including phone calls, emails, and online chats. To ensure consistency and adherence to standards, Quality Operations Analysts regularly perform reviews. The QA ratings are used to identify areas for individual performance improvement, process gaps, and training requirements.

Time to Resolution (TTR)

TTR calculates the typical time required to address customer concerns or finish activities. It serves as a crucial KPI for evaluating operational effectiveness. To improve processes, remove bottlenecks, and decrease customer wait times while also increasing overall productivity and customer happiness, the Quality Operations Analyst examines TTR data.

Employee Engagement and Satisfaction

The involvement and contentment of an organization's workforce have a significant impact on its success. To assess morale and pinpoint areas that want improvement, the Quality Operations Analyst may consult employee surveys and comments. Employees who are satisfied and engaged are more likely to provide superior customer service and support the growth of the business.

Error and Defect Rates

This KPI is concerned with the quantity and regularity of mistakes or flaws in goods or services. To identify the underlying reasons and apply remedial measures, Quality Operations Analysts examine mistake and defect rates. The overall quality and dependability of the company's goods are improved by lowering mistake rates.

Process Efficiency Metrics

Cycle time, throughput, and capacity utilization are examples of process efficiency measures that provide light on how well-functioning operational processes are. The Quality Operations Analyst may find possibilities for simplifying procedures, cutting waste, and improving resource allocation by analyzing these data.

Cost of Poor Quality (COPQ)

COPQ stands for "cost of poor quality," which includes all expenditures such as rework, returns, warranty claims, and missed sales opportunities. This KPI illustrates the financial implications of quality problems and directs the Quality Operations Analyst in selecting cost-saving and profitability-boosting improvement initiatives.

Customer Retention Rate

Customer retention is a major factor in the expansion and success of businesses. The proportion of customers that continue to conduct business with the firm over a certain time period is measured by the customer retention rate. This KPI is used by the Quality Operations Analyst to evaluate the success of customer retention initiatives and spot any problems that might be driving away current clients.

|

View the gallery of examples of dashboards and visualizations. |

On-Time Delivery Performance

On-Time Delivery (OTD) Performance is a crucial KPI for businesses engaged in manufacturing or supply chain activities. It calculates the proportion of orders or shipments that reach consumers on time. To make sure the business is fulfilling delivery obligations, boosting customer happiness, and keeping a competitive advantage, the Quality Operations Analyst monitors OTD.

Employee Training and Certification

For operations to remain high-quality, personnel skills and knowledge must be continually improved. The proportion of staff who have finished necessary training and earned certifications is tracked by the Quality Operations Analyst. This KPI assists in identifying training needs and guarantees that the staff is adequately prepared to carry out its duties.

Defect Tracking and Root Cause Analysis

Defect monitoring entails keeping track of and evaluating the kinds and quantity of flaws discovered in goods or services. To determine the underlying causes of these flaws, the Quality Operations Analyst performs root cause analysis. The company may proactively avoid future quality concerns and improve production or service processes by addressing fundamental causes.

Supplier Performance

Supplier Performance is a critical KPI in sectors that depend on suppliers. It gauges how well external suppliers perform in terms of on-time delivery, high-quality products, and adherence to requirements. To guarantee that the company maintains a strong and dependable supply chain and, eventually, raises the caliber of the final goods or services provided, the Quality Operations Analyst assesses supplier performance data.

|

Learn about the top 10 features of embedded business intelligence. |

Employee Productivity Metrics

Metrics for measuring employee productivity evaluate the effectiveness and production of specific people or teams inside the company. These measurements, including activities performed per hour or sales per employee, are used by the Quality Operations Analyst to identify high-performing people or teams and to spot areas that may need more assistance or training.

Compliance and Regulatory Adherence

Compliance and regulatory adherence are crucial for sectors working under rigorous regulatory regimes. The Quality Operations Analyst makes sure the company complies with all legal requirements and adheres to accepted business practices. Serious repercussions, including as penalties, legal troubles, and harm to the company's image, may result from noncompliance.

Cost per Quality (CPQ)

Cost per Quality (CPQ) is a statistic that gauges how much it costs a business to maintain quality standards. It accounts for the expenses connected to training, quality assurance, and other quality-related operations. The Quality Operations Analyst monitors CPQ to identify potential for cost reduction while maintaining high-quality operations.