InetSoft's Reporting Tool for SAP

Enterprises that utilize SAP as their primary data processing software will further enhance their ERP capabilities with the addition of InetSoft's easy, agile, robust StyleBI BI software application.

The software application maximizes self-service, cutting out IT intervention and allocating usability for business users. StyleBI's easy drag-and-drop interface automatically writes queries that manipulates massive amounts of data, for accurate reporting.

Deployed within weeks and requiring a minimum of training, even those who lack IT skills can use Style Intelligence to manipulate data relationships and create visualizations. Business end-users obtain the direct control of real-time data mashups and automated reporting capabilities.

Merge Data From Diverse Sources With Ease

StyleBI can simultaneously manage and integrate raw data from all SAP suites and modules. The BI software application is not only restricted to SAP products, however; it is also capable of integrating data from other ERP solutions such as JD Software, Peoplesoft, and Oracles, in addition to numerous other data sources.

InetSoft's data mashup engine is a significant feature that combines and consolidates massive amounts of data, which is structured to be manipulated and analyzed within a single-view. With the patent pending Data Block Technology, users can integrate their own data spreadsheets from remote sources. Even partners and vendors can create data mashups without a predefined data model.

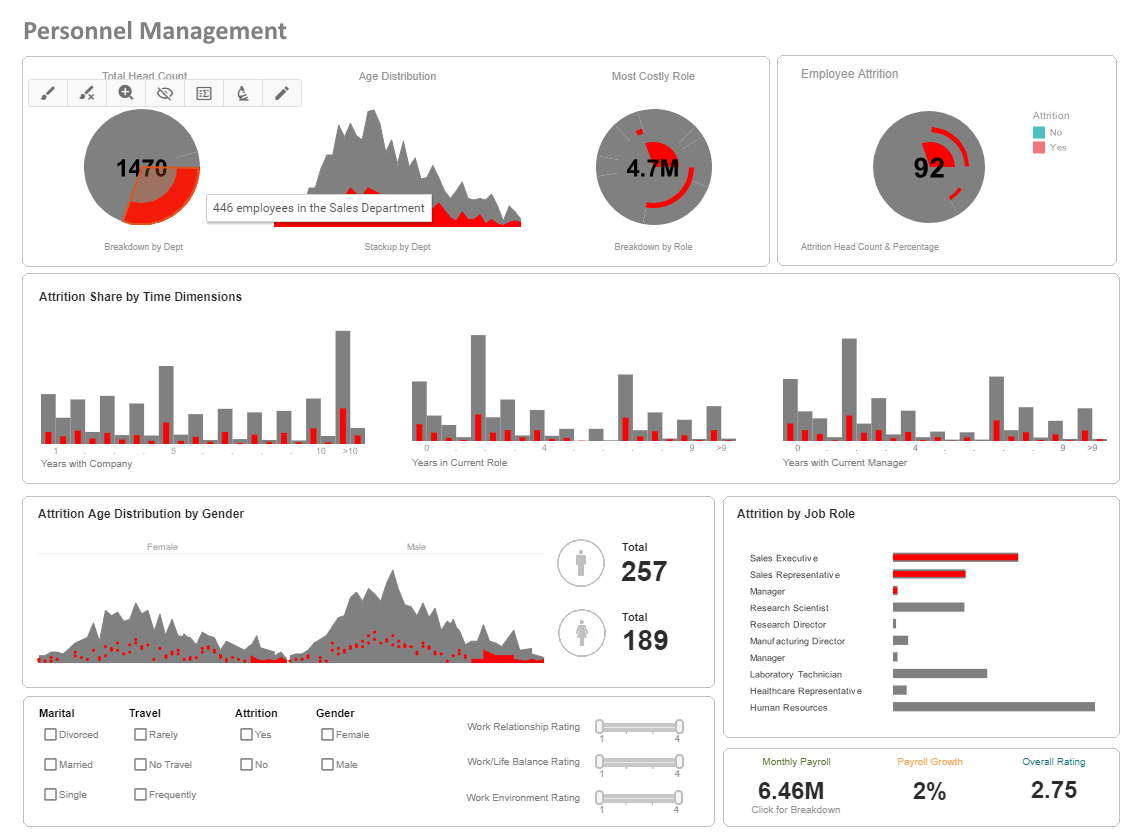

Enhanced Report and Dashboard Aesthetics

Even though SAP has proven itself to be a suitable ERP data processing software, it falls short in the ability to create visually enticing reports and interactive dashboards. InetSoft's all-inclusive BI platform gives end-users an unlimited range of customizations of chart styles, to add interactivity to their reports and dashboards. Users will be able to deliver sophisticated and professional quality reports for presentations, and real-time visualizations for data exploration.

StyleBI is deployed as a web-based solution that enables users to access and modify reports and dashboards from any web browser or mobile device. Any affiliate within the organization can access, share, and analyze real-time business information, off or on-premise.

StyleBI's reporting and dashboarding tools amplify the functionality of SAP, with its versatile data mashup engine, straight-forward data analysis, and the ability to create visually alluring reports and interactive dashboards.

Deutsche MechAntrieb GmbH Switches from SAP to InetSoft for Reporting

Deutsche MechAntrieb GmbH, a mid-sized German manufacturer of diesel engines for industrial and marine applications, recently made a deliberate shift in its reporting stack: moving away from SAP’s embedded reporting modules to adopt InetSoft’s Style Intelligence as its primary reporting and dashboarding tool. The decision was driven by practical needs — faster access to operational KPIs, less reliance on scarce BI development resources, and the desire to deliver embedded, role-specific analytics to engineers, plant managers, and the executive team without sacrificial performance or governance. The switch was not a rejection of SAP as a transactional system, but a recognition that reporting requirements had outgrown the agility and usability of SAP’s out-of-the-box reporting.

Pain Points with SAP Reporting

For years Deutsche MechAntrieb relied on SAP for ERP, production planning, and master data; reports were generated through SAP’s native tools and a handful of custom ABAP reports. As the company expanded into new product lines and retrofitting services, reporting demands multiplied: shop-floor telemetry from PLCs and IoT sensors needed to be joined with ERP batch records, warranty claims, and supplier quality data. Creating these cross-source reports in SAP required heavy developer involvement, long backlog cycles, and frequent rework when metrics changed. Managers often received static PDFs or spreadsheets that lacked interactivity, and the latency degraded decision quality on issues like scrap rates, engine performance trends, and on-time delivery.

Why InetSoft Was Attractive

InetSoft offered several characteristics that matched Deutsche MechAntrieb’s needs. First, its data mashup capabilities let the company join SAP tables with sensor streams, MES exports, and external logistics feeds without building a massive intermediary data pipeline. Second, InetSoft’s web-based designer empowered non-technical users — production leads and QA engineers — to create or tweak dashboards via drag-and-drop, reducing time-to-insight. Third, InetSoft’s embeddability allowed the analytics team to place interactive dashboards directly into the company portal used by plant operators and service technicians, providing contextual KPIs next to operational workflows. Critically, the licensing model and deployment flexibility fit the company’s cost and compliance constraints; they could host the BI layer on-premises while keeping SAP as the single system of record.

Implementation Strategy

The rollout was executed in phases. Phase one replicated key SAP reports in InetSoft to validate data fidelity: production throughput, yield by batch, supplier defect rates, and warranty cost by model. Phase two introduced mashups: combining sensor temperature profiles with batch IDs to visualize conditions leading to metallurgical anomalies. Phase three focused on self-service: targeted training sessions enabled line managers to create shift-level dashboards that automated what used to be weekly manual reconciliations. Throughout, the BI team ran InetSoft in parallel with existing SAP reports to build trust and provide a fallback while users acclimated.

Operational and Financial Impact

Within six months, Deutsche MechAntrieb reported meaningful gains. Production throughput visibility reduced unplanned downtime by enabling quicker root-cause analysis; by spotting a pattern of bearing overheating tied to a supplier’s batch, the company avoided extended failures and lowered scrap by nearly 14% on affected lines. Warranty analytics surfaced high-cost failure modes earlier, allowing engineering to redesign a vulnerable component and reduce warranty spend. From a cost perspective, the ability to create and maintain dashboards without constant developer cycles translated to a lower cost-to-serve for analytics: IT freed up several developer weeks per quarter previously dedicated to report changes, and the business reclaimed those hours for process improvement.

Cultural and Process Changes

Beyond metrics, the transition sparked cultural change. Operators began their shifts by reviewing live KPIs embedded in the plant portal, turning analytics into a routine part of operations rather than an afterthought. Accountability changed: targets, trends, and exceptions were visible and discussed in daily huddles, which shortened problem resolution cycles. The analytics team also adopted an iterative delivery model — releasing small dashboard improvements weekly rather than waiting for quarterly reporting cycles — which improved adoption and lowered resistance to change.

Challenges and Lessons Learned

The migration wasn’t frictionless. Ensuring consistent master data between SAP and the BI layer required governance: the company implemented a lightweight data dictionary and reconciliation jobs to prevent divergent metrics. Security and access control needed careful mapping — translating SAP roles to InetSoft dashboards while preserving data privacy for customer and warranty records. Finally, change management was crucial; the most successful teams were those who combined training with clear use cases, templates, and a short "office hours" cadence for the analytics team to help users build their first dashboards.