Manufacturing Analytics For Quality Control

Quality control has always been an important aspect of manufacturing. Good quality control can bring lots of benefits to the business, including improving efficiency and cost, increasing customer loyalty, gaining new customers from referrals, and maintaining or improving market position. On the other hand, when things go awry, quality issues can drive up material and labor costs, threaten margins, result in missed orders, and harm business reputation.

As more and more data is being collected in recent years, organizing, accessing, and analyzing quality control data has become one of the biggest challenges that manufacturing companies face today. Automating tasks that ensure real-time monitoring of the quality control process can enable the rapid deployment and correction of quality problems when they occur.

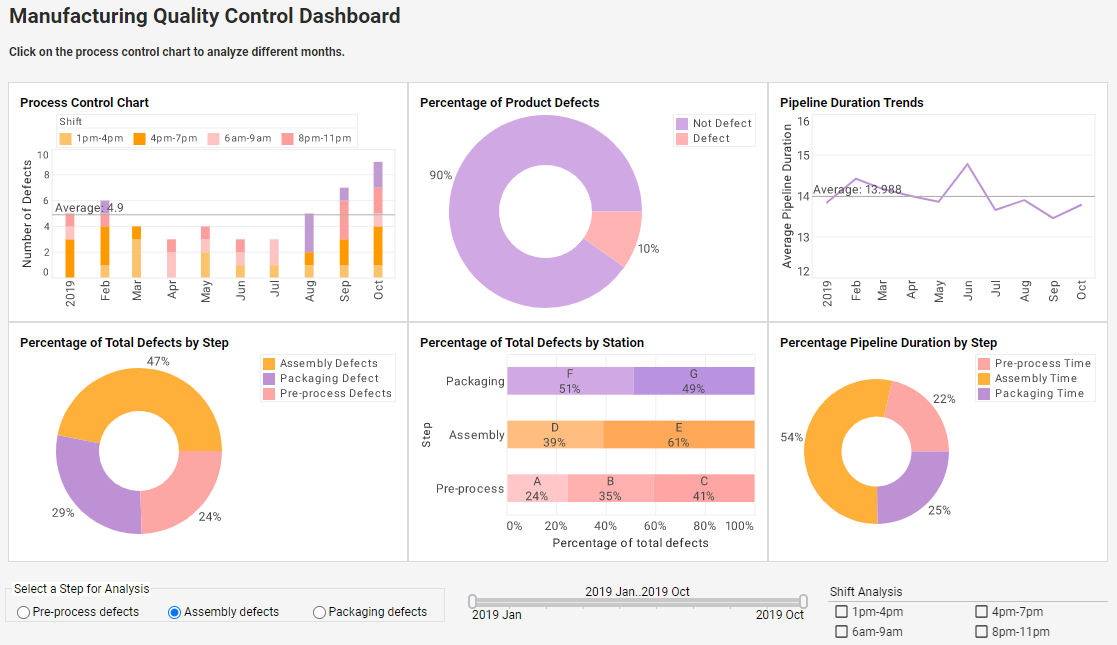

To this end, InetSoft has created a Manufacturing Quality Control Dashboard that mashes up quality control data, connects all the pieces of the supply chain in one place, and presents detailed information ready for instant actionable insights.

Manufacturing Reporting for Quality Control

This Manufacturing Quality Control Dashboard enables quality control managers to monitor and analyze everything, from defects rate and pipeline duration to shift performance and technician performance, all in one dynamic view. With built-in filtering components, manufacturing professionals can easily slice and dice data with simple point-and-click methods to get various insights.

For example, by glancing at the process control chart, manufacturing managers can quickly see that something has been going wrong since August, when the number of defects started to increase over the course of several months. They can investigate deeper by using the process control chart as an interactive filter. By simply clicking on a specific month and shift, the whole dashboard will adapt, enabling manufacturing managers to perform further analysis without writing any code or creating extra charts.

Apart from performing analysis over time, the Manufacturing Quality Control Dashboard also allows professionals to perform analysis for different steps with the built-in selection list. By selecting the step they are interested in they can understand how the defect rate for a specific step changes over time, they can identify the shift that needs the most attention, and they can immediately get a list of technicians that should be scrutinized for further investigation.

With InetSoft's Manufacturing Quality Control dashboard, the quality control process can be placed on a path of continuous improvement, quickly and efficiently.

Blown Film Extrusion Manufacturer Moves from AG TrendMiner to StyleBI for Quality Control Analytics

In the world of plastics manufacturing, few industries are as specialized and demanding as blown film extrusion. These manufacturers produce thin, durable plastic films used in everything from agricultural covers to food packaging. Because the process involves melting polymers, blowing them into thin tubes, and carefully cooling them to maintain uniform thickness, the margin for error is extremely small. Quality control is the lifeblood of the business, as even minor variations in thickness, opacity, or tensile strength can render entire batches unusable. One such company, which we’ll call FilmFlow Industries, had been relying on AG TrendMiner for process data analysis, but ultimately switched to StyleBI to build a more holistic, flexible, and user-driven quality control analytics system.

Why AG TrendMiner Fell Short

TrendMiner is a capable tool for analyzing time-series process data. For FilmFlow Industries, it was helpful in examining polymer melt temperatures, line speeds, and cooling rates over time. However, the company found that TrendMiner often forced a “control-room” approach to analytics. Engineers could slice and compare sensor trends, but integrating those insights with quality lab data, supplier resin properties, and customer defect reports was difficult. The analytics stayed in silos, and operators on the shop floor rarely saw the bigger picture.

Another challenge was accessibility. TrendMiner’s learning curve limited use to process engineers, leaving quality managers and line supervisors dependent on reports rather than being able to explore the data themselves. In a manufacturing context where rapid iteration and real-time decisions matter, this created bottlenecks.

Enter StyleBI: A Unified Platform

By switching to StyleBI, FilmFlow Industries was able to break down these silos and centralize quality control analytics. StyleBI’s open-source foundation allowed easy connections to multiple systems: shop-floor PLCs, laboratory databases, ERP material records, and even spreadsheets maintained by quality teams. Instead of simply viewing trend graphs, FilmFlow built interactive dashboards where users could mash up sensor logs with downstream test results and supplier batch certifications.

This integration was critical. For example, when tensile strength dips below tolerance, StyleBI dashboards can now immediately correlate the defect to resin supplier lots, operator shift schedules, or minor variations in blower pressure. This full-context visibility has changed the company’s approach from reactive problem-solving to proactive quality assurance.

Building Quality Control Dashboards

FilmFlow’s dashboards evolved through collaboration between engineers and quality teams. Some of the key analytics they developed included:

- Film Thickness Heatmaps: Pulling inline gauge data into StyleBI to visualize where across the width of the film variation occurs, enabling fast mechanical adjustments.

- Defect Pareto Charts: Merging customer complaint categories with in-house QC tests to prioritize which quality issues to resolve first.

- Supplier Performance Tracking: Correlating resin supplier lots with downstream extrusion performance, giving purchasing teams leverage in negotiations.

- Process Stability Dashboards: Overlaying process control parameters (temperature, pressure, cooling rate) with quality metrics to identify early warning patterns.

- Scrap Cost Analytics: Converting scrap quantities into financial impact, allowing management to quantify the ROI of process improvements.

Why StyleBI Fit the Culture Better

The real difference wasn’t just technical capability; it was how StyleBI aligned with FilmFlow’s culture. As an open-source platform, it encouraged tinkering and iteration. Quality managers could build their own dashboards without waiting weeks for IT intervention. Supervisors on the shop floor could drill into KPIs and see live updates. This democratization of analytics gave everyone a stake in quality control and reduced the lag between detecting a problem and acting on it.

StyleBI’s mashup engine also provided a pragmatic edge. Instead of reengineering data pipelines every time a new supplier, test, or sensor type was introduced, the mashup layer let the company add and blend new data sources on the fly. For a manufacturer constantly adapting to customer specifications, this flexibility was invaluable.

Outcomes of the Switch

Within the first year of switching to StyleBI, FilmFlow Industries saw tangible results:

- Reduction in scrap rate by 12% thanks to early detection of process drift.

- Improved customer satisfaction as complaint rates dropped due to consistent film quality.

- Faster root cause analysis with integrated dashboards cutting problem-solving time by half.

- Empowered workforce with supervisors and operators actively using dashboards rather than waiting for engineering reports.

Beyond these measurable gains, the shift also built confidence in the company’s ability to scale production while maintaining quality. Customers noticed the consistency, and FilmFlow leveraged this reputation to win new contracts in the packaging sector.