Challenges in Supply Chain Analytics

This is the transcript of a podcast hosted by InetSoft on the topic of "Supply Chain Analytics." The speaker is Abhishek Gupta, Product Manager at InetSoft.

What are some of the key challenges in planning for manufacturing companies?

One of the key challenges manufacturing companies is how to make the planning process much better, using much better data to do much better forecasting, particularly in the area of supply chain management. This is an area that is complex because supply chain management needs to bring together a lot of different processes.

And if you want to bring together processes, you need first to bring together the right information. Every business unit has to deal with the same information and with the same analytics that they can use for doing the planning. This is, I think, one of the key challenges which is still found in many companies.

Why is analytics a key driver for success?

Analytics closes the loop between process management and the results of the processes and the data that you get out of the processes. So if you collect all this data, you are doing the analytics, and you are doing the planning based on the analytics in best case in real time, for example, and you use it also for planning.

Why is Supply Chain Analytics Important?

Especially, if you talk about supply chain management, you always talk about the resources, about forecasting, predictive forecasting. You need to know what you have to produce, but also you talk about new logistics and new supply chain management, and this means knowing where are all the resources and the stocks are in the supply chain.

This means you need to have really good analytical systems. Otherwise you don't have the right information, and the planning will suffer. The effect is that you have the so-called financial underperformance.

What exactly is supply chain analytics?

Well, you can supply chain analytics to supply chain management. I see supply chain management as something that is a horizontal discipline. Supply chain analytics is going more in the vertical way.

With supply chain management, you try to connect all processes together in automotive or other manufacturing industries. With supply chain analytics, you try to bring together different business units and the information demand they have just to bring it together and to have the same information to get the single version of the truth so that everyone can do the same planning and to get the same results out of the planning that they could use for supply chain management.

How Does InetSoft Help Supply Chain Management?

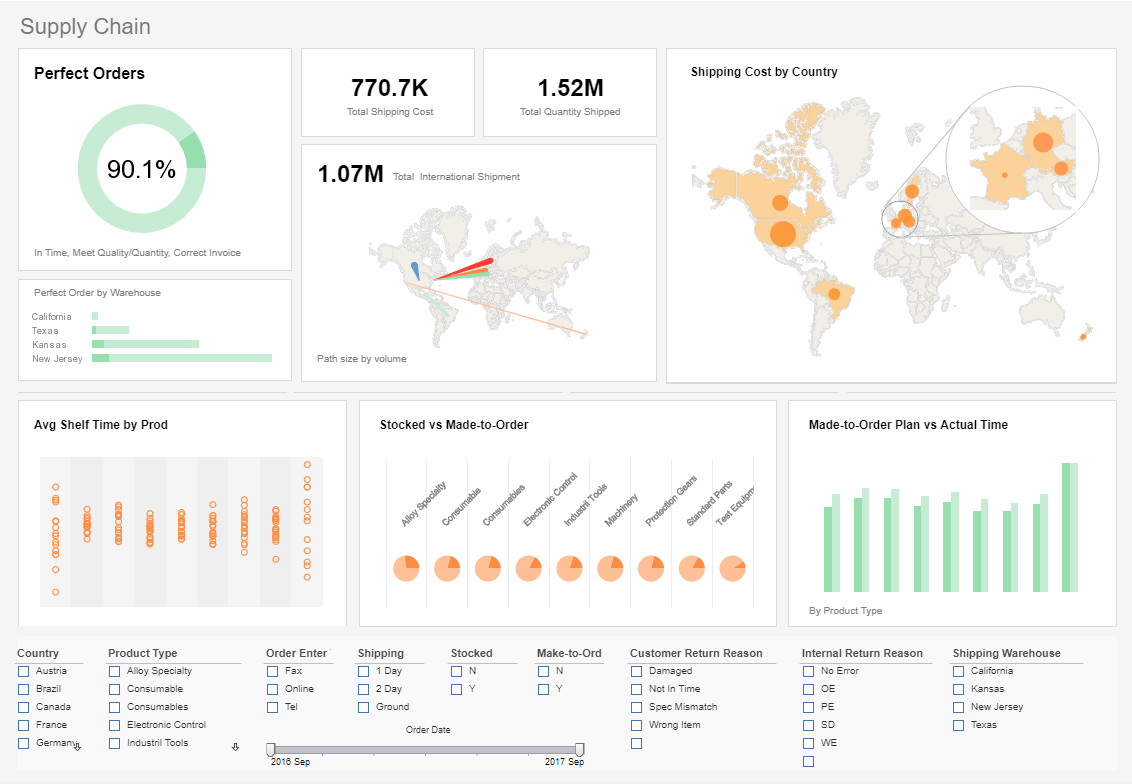

InetSoft's BI application is perfect for this challenge because the strength of the software in bringing all this data together, and we bring it together in a way not only just looking into the back but also looking into the future. We bring it together in real time so that you can make the right decisions and to get the right analytics that you need for doing this supply chain analytics.

With our data mashup engine we have the capability to get all this data together, and there is a lot of data that you could collect in automotive companies for example, starting backwards with quality and warranty, with all the production data, with all the data of the development of cars. So there are terabytes of data you can collect and that you need to bring together to form the single version of the truth in order to do all the planning.

A Poultry Hatchery's Shift: From IIBM to InetSoft for Supply Chain Mastery

In poultry production, where timing is everything and a single delay can mean the difference between profit and loss, supply chain analytics isn't just a tool—it's a lifeline. At Golden Feather Hatchery, a mid-sized operation nestled in the rolling hills of the Midwest, the stakes have never been higher. Specializing in incubating and distributing day-old chicks to farms across three states, the hatchery processes over a million birds annually. But like many in the industry, Golden Feather grappled with volatile feed costs, unpredictable disease outbreaks, and the razor-thin margins of perishable goods. For years, their backbone was IIBM, a robust but aging business intelligence platform. It had served them well in the early days, crunching numbers on egg sourcing and hatch rates. Yet, as the hatchery scaled, IIBM's limitations became glaringly apparent, prompting a bold pivot to InetSoft—a nimble, visualization-driven analytics suite tailored for supply chain complexities.

The troubles with IIBM began subtly but snowballed into operational nightmares. Installed a decade ago, the system excelled at batch reporting: end-of-month summaries of supplier performance, inventory turnover, and basic demand forecasting based on historical sales data. Managers could generate static spreadsheets outlining egg shipments from breeding farms or track vaccination compliance. However, in an industry where chicks must reach growers within 24 hours of hatching to minimize stress and mortality, IIBM fell short on real-time insights. Its clunky interface required manual data imports from disparate sources—IoT sensors monitoring incubator humidity, ERP systems logging feed deliveries, and weather APIs predicting transport disruptions. Queries often took hours to run, leaving teams blind to emerging issues like a sudden spike in regional avian flu risks or a supplier's delayed egg delivery.

One particularly harrowing incident crystallized the need for change. During a brutal winter storm in early 2024, a forecast error in IIBM underestimated demand for broiler chicks by 20 percent. Eggs piled up in storage, risking spoilage, while downstream farms faced shortages that idled their operations for days. The fallout? A $150,000 hit in lost revenue and goodwill. "We were reactive, not proactive," recalls hatchery operations director Elena Vasquez. "IIBM gave us hindsight, but we needed foresight—tools to simulate scenarios, visualize bottlenecks, and alert us before problems escalated." The industry-wide challenges amplified this pain: rising corn prices inflating feed costs by 15 percent year-over-year, labor shortages delaying chick sorting, and regulatory pressures for traceability in every supply chain link, from grandparent stock to the farm gate.

The search for a successor began with a thorough RFP process, evaluating heavyweights like SAP and Tableau alongside niche players. InetSoft emerged as the frontrunner, praised for its drag-and-drop dashboard builder, seamless integration with agricultural IoT devices, and laser focus on supply chain analytics. Unlike IIBM's monolithic architecture, InetSoft promised pixel-perfect, interactive visualizations that non-technical users could wield effortlessly. Its Style Intelligence platform, with modules for predictive modeling and anomaly detection, aligned perfectly with poultry's perishable dynamics. "We were drawn to how InetSoft turned complex data into intuitive stories," Vasquez says. "Dashboards that drill down from global egg flows to individual incubator performance—it's like having a crystal ball for our chain."

Transitioning wasn't seamless, but Golden Feather's phased rollout minimized disruptions. Phase one, spanning three months, focused on data migration. IT teams mapped IIBM's legacy datasets—over 500 gigabytes of hatch logs, supplier contracts, and mortality metrics—into InetSoft's cloud-based repository. Cleansing was arduous; duplicate entries from manual logs had to be scrubbed, and APIs retrofitted for real-time feeds from humidity sensors and GPS-tracked chick transports. Vendor support proved invaluable, with InetSoft's consultants embedding on-site to customize workflows. Phase two rolled out training: 40 staffers, from hatch technicians to logistics coordinators, spent two weeks in hands-on sessions. The drag-and-drop interface won skeptics over quickly; one sorter quipped, "It's like building with Lego instead of welding pipes." By phase three, live dashboards lit up the control room: a heat map of egg quality risks, a Gantt chart for delivery routes optimized against weather, and KPI cards flashing alerts for hatch rates dipping below 85 percent.

The payoff arrived swiftly, transforming Golden Feather's operations. Forecasting accuracy surged 35 percent, thanks to InetSoft's machine learning algorithms that ingest variables like seasonal broiler demand and feed price volatility. In one instance, predictive analytics flagged a potential bottleneck in a key supplier's egg production, allowing a preemptive reroute that saved 5,000 chicks from delay-induced losses. Inventory management sharpened too; dynamic replenishment models reduced overstock of hatching eggs by 22 percent, curbing waste in an era of expiry-sensitive goods. Chick mortality during transit plummeted 18 percent, as geo-fenced dashboards rerouted trucks around storms in real time. Cost savings? A conservative estimate pegs annual gains at $250,000, from trimmed fuel expenses to fewer emergency buys of premium feed.

Beyond metrics, InetSoft fostered a data-driven culture. Frontline workers now access mobile dashboards on tablets, spotting anomalies like uneven incubator temperatures during rounds. Vasquez's team runs "what-if" simulations weekly: What if avian flu hits a Midwest flock? How does it ripple to our chick orders? These exercises have bolstered resilience, especially amid ongoing challenges like climate-driven heat waves stressing transport or geopolitical tensions hiking import tariffs on breeding stock. Integration with third-party tools—weather services, vet databases—creates a unified view, ensuring compliance with USDA traceability mandates down to the lot level.

Looking ahead, Golden Feather eyes expansions: AI-enhanced biosecurity modeling to preempt disease vectors, or blockchain tie-ins for end-to-end provenance that appeals to eco-conscious buyers. The switch from IIBM to InetSoft wasn't just an upgrade; it was a reinvention, proving that in poultry's unforgiving supply chain, agility trumps legacy every time. As Vasquez puts it, "We're no longer chasing shadows—we're steering the flock." For hatcheries everywhere, this tale underscores a timely truth: In an industry where every egg counts, the right analytics can hatch a brighter future.