Firearm Manufacturer Leverages InetSoft's StyleBI for Advanced Analytics

This article explores how a firearm manufacturer, Precision Arms Co., harnessed InetSoft’s open-source StyleBI platform to revolutionize its operational efficiency, supply chain management, and regulatory compliance, offering insights into the technical implementation and benefits for an IT audience.

Precision Arms Co., a mid-sized firearm manufacturer based in the United States, produces a range of products, from handguns to tactical rifles, for both civilian and law enforcement markets. The company faced several challenges common to the industry:

- Data Silos: Data was scattered across multiple systems, including an SAP ERP for inventory and production, a Salesforce CRM for customer and sales data, and compliance databases for tracking serial numbers and regulatory requirements. These siloed systems hindered comprehensive analysis and timely decision-making.

- Regulatory Compliance: The firearm industry is subject to stringent regulations, such as those enforced by the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). Tracking serial numbers, production batches, and dealer transactions required real-time, auditable reporting.

- Supply Chain Volatility: Fluctuating raw material costs, supplier reliability, and logistics complexities demanded dynamic monitoring to avoid production delays.

- Market Responsiveness: Rapid shifts in consumer demand, such as spikes in sales following legislative changes, required agile forecasting and inventory management.

The IT team at Precision Arms was tasked with finding a BI solution that could unify these data sources, deliver real-time insights, and enable non-technical staff—such as production managers and compliance officers—to access and analyze data without heavy IT intervention.

Why StyleBI?

InetSoft's StyleBI, a web-based BI platform, was selected for its ease of use, robust data mashup capabilities, and open-source flexibility. For IT professionals, StyleBI offers several technical advantages that align with the needs of a firearm manufacturer:

- Web-Based, Zero-Client Architecture: StyleBI operates as a Java-based server application, accessible via any modern web browser (e.g., Chrome, Firefox, Edge) without client-side installations. This reduces deployment and maintenance overhead, allowing Precision Arms' distributed teams—across production facilities, warehouses, and offices—to access dashboards on desktops and mobile devices.

- Data Mashup Engine: StyleBI's patent-pending Data Block technology enables seamless integration of disparate data sources, such as SAP ERP, Salesforce CRM, and relational databases like MySQL for compliance tracking. This was critical for Precision Arms, which needed to combine structured data (e.g., production schedules) with semi-structured data (e.g., supplier contracts in CSV format).

- Scalability and Performance: StyleBI's server-based architecture supports load balancing and failover through J2EE server clustering, ensuring high availability for handling large transactional datasets. Its data streaming technology processes only relevant data chunks, enabling faster report loading—a key requirement for real-time production monitoring.

- Self-Service Analytics: StyleBI's drag-and-drop interface and visual data pipeline empower non-technical users to create reports and dashboards, reducing IT dependency. This was a game-changer for Precision Arms' compliance and production teams, who needed to generate ad hoc reports without coding expertise.

- Open-Source Flexibility: As an open-source platform, StyleBI allows IT teams to customize and extend functionality, integrating with existing systems and workflows. This was particularly appealing for Precision Arms' IT department, which required a solution compatible with their Java-based infrastructure.

Implementation Process

The implementation of StyleBI at Precision Arms was led by the IT team in collaboration with department heads to ensure alignment with business needs. The process unfolded in several key phases:

1. Data Source Integration

The IT team began by mapping out data sources critical to operations:

- SAP ERP: Provided inventory levels, production schedules, and procurement data.

- Salesforce CRM: Contained customer orders, sales trends, and dealer performance metrics.

- MySQL Compliance Database: Stored serial numbers, ATF audit trails, and regulatory reporting data.

- IoT Sensors: Monitored real-time production line metrics, such as machine uptime and defect rates.

Using StyleBI's data mashup engine, the team created virtual data blocks to normalize and combine these sources. For example, they integrated SAP inventory data with IoT sensor outputs to monitor raw material usage in real time. The visual data pipeline simplified transformations, such as standardizing date formats across systems, without requiring complex SQL queries.

2. Dashboard Design

The IT team worked with stakeholders to design tailored dashboards for different departments:

- Production Dashboard: Displayed KPIs like production throughput, machine downtime, and defect rates. Visualizations included gauges for live sensor data and line charts for production trends.

- Supply Chain Dashboard: Tracked supplier delivery times, raw material costs, and inventory turnover. Bar charts highlighted supplier performance, while automated alerts flagged delays.

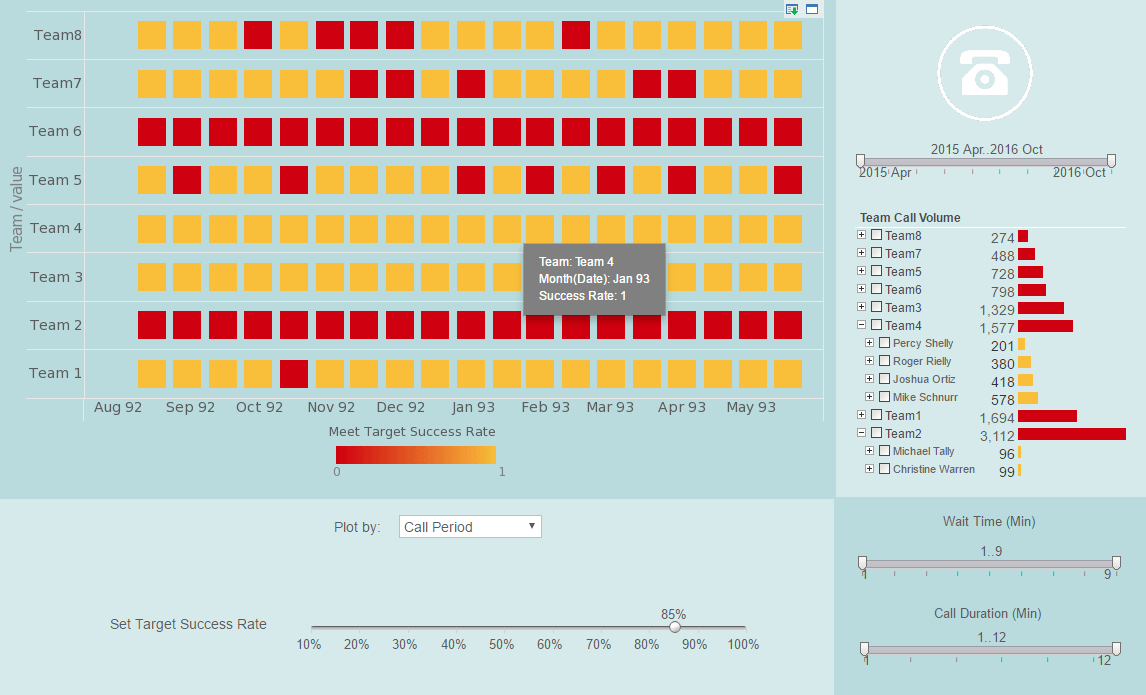

- Compliance Dashboard: Monitored serial number tracking, ATF audit compliance, and batch traceability. Tables and drill-down reports allowed compliance officers to investigate specific transactions.

- Sales Dashboard: Analyzed customer orders, regional sales trends, and dealer performance, using heatmaps to visualize demand by geography.

StyleBI's drag-and-drop designer enabled rapid prototyping, with department heads providing feedback to refine visualizations. The platform's interactive features, such as sliders and selection lists, allowed users to filter data dynamically—e.g., viewing production metrics for a specific product line or time period.

3. Deployment and Scalability

StyleBI was deployed on a Linux-based server cluster to ensure scalability and high availability. The IT team configured load balancing to handle peak usage during month-end reporting cycles. The platform's zero-client architecture eliminated the need for client-side installations, enabling seamless access across Precision Arms' facilities. Mobile compatibility allowed field sales teams to access sales dashboards on iPads and smartphones, enhancing responsiveness to market shifts.

4. User Training and Adoption

To maximize self-service, the IT team conducted training sessions for production managers, compliance officers, and sales staff. StyleBI's intuitive interface, requiring only basic Excel skills, ensured quick adoption. For example, compliance officers could generate ATF-compliant reports using pre-built templates, while production managers created ad hoc reports to analyze machine performance.

Technical Benefits for IT Teams

For IT professionals, StyleBI delivered several technical advantages:

- Ease of Integration: The platform's Java API and support for REST APIs simplified integration with Precision Arms' existing systems, reducing development time.

- Low Maintenance: The zero-client, web-based architecture minimized IT overhead for software updates and user support.

- Security: StyleBI's customizable access controls allowed the IT team to restrict data visibility—e.g., ensuring compliance officers could only access regulatory data. Integration with existing authentication systems (e.g., LDAP) streamlined user management.

- Performance Optimization: Data streaming and caching ensured fast report loading, even for large datasets like production logs. Parallel processing handled real-time IoT data streams efficiently.

Business Outcomes

The adoption of StyleBI transformed Precision Arms' operations:

- Improved Compliance: Real-time serial number tracking and automated ATF reports reduced audit preparation time by 40%, ensuring regulatory compliance.

- Supply Chain Efficiency: Dashboards identified underperforming suppliers, reducing delivery delays by 25%. Real-time inventory monitoring cut excess stock by 15%, lowering costs.

- Production Optimization: IoT-integrated dashboards reduced machine downtime by 20% through predictive maintenance alerts.

- Market Agility: Sales dashboards enabled rapid response to demand spikes, increasing order fulfillment rates by 10%.

Lessons Learned

The IT team at Precision Arms noted several lessons:

- Stakeholder Collaboration: Early involvement of department heads ensured dashboards met specific needs, boosting adoption.

- Incremental Rollout: Starting with a single department (production) allowed the team to refine the implementation before scaling.

- Training Investment: Comprehensive training was critical for empowering non-technical users, reducing IT support requests.