What KPIs and Analytics Does a Manufacturer of CBD Hemp Products Use

A manufacturer of CBD hemp products operates in a highly competitive and tightly regulated market. From raw material procurement to product formulation, and from packaging to distribution, each step in the value chain must be tightly monitored to ensure compliance, quality, and profitability. To thrive in this environment, companies must rely heavily on key performance indicators (KPIs) and advanced analytics to guide decisions, optimize operations, and manage risk.

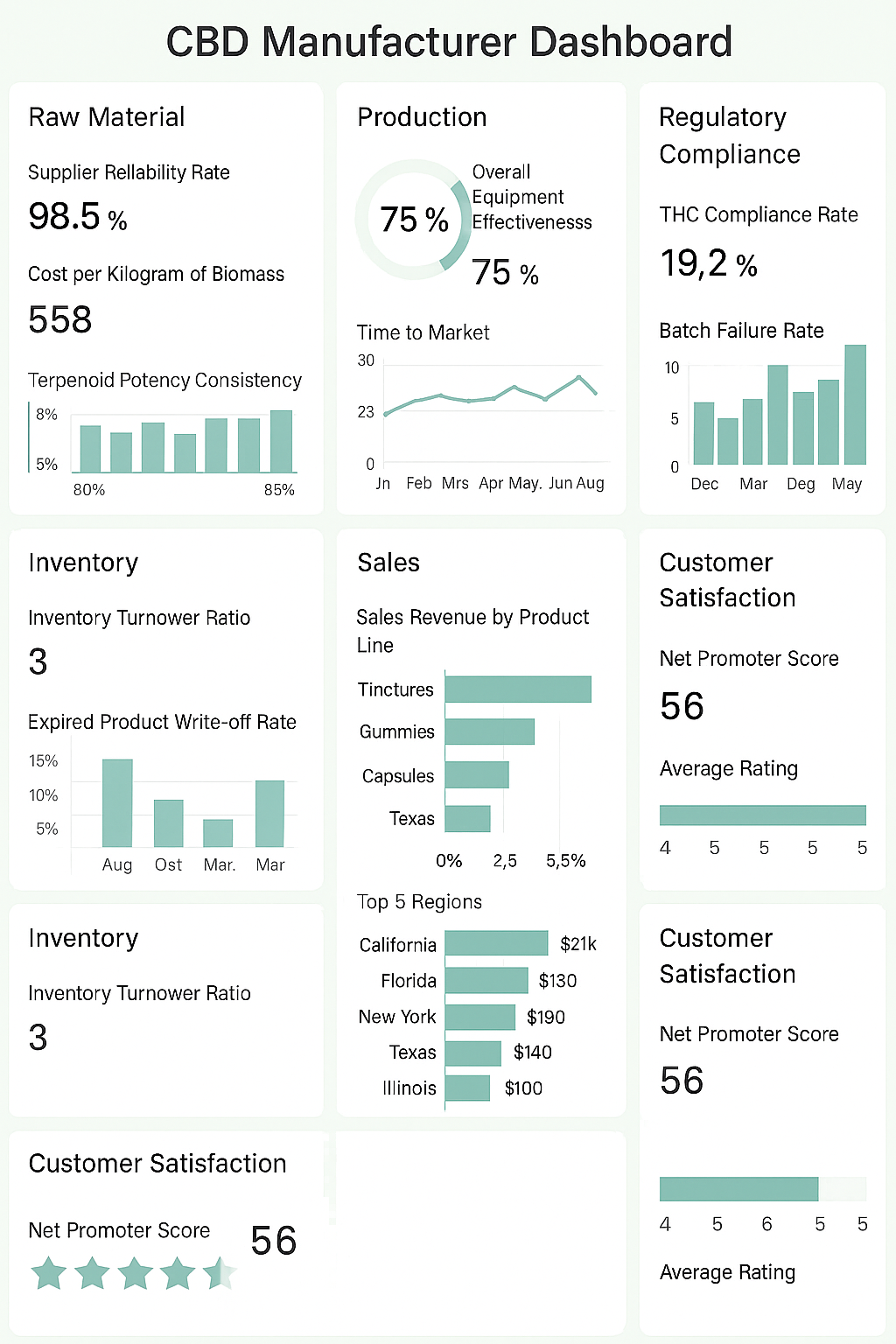

In this article, we’ll explore the essential KPIs and analytics tools used by a CBD hemp product manufacturer. We’ll cover various domains including cultivation sourcing, compliance, production efficiency, inventory control, sales performance, customer satisfaction, and financial health. We'll also examine how data visualization and business intelligence (BI) tools like InetSoft’s StyleBI can provide a holistic view of performance metrics and drive better decision-making.

However, InetSoft's application, StyleBI, is designed to be as easy as possible to deploy and use.

1. Raw Material and Supply Chain KPIs

For a CBD manufacturer, the supply chain begins at the farm. Whether sourcing hemp biomass or CBD isolate, quality and reliability are paramount. Supply chain KPIs focus on supplier performance, raw material quality, and input costs.

- Supplier Reliability Rate: Measures the percentage of on-time and complete deliveries. Delays in hemp biomass delivery can disrupt production timelines.

- Cannabinoid Potency Consistency: Variations in CBD, THC, or other cannabinoids can alter final product formulations and affect compliance.

- Cost per Kilogram of Biomass: Tracks pricing trends from various growers or brokers. Fluctuations in this KPI impact product pricing and margins.

- Pesticide and Heavy Metal Screening Rates: CBD manufacturers must ensure all inputs meet strict safety standards. Regular testing and pass rates are critical.

- Lead Time from Order to Delivery: Helps assess logistics efficiency and predict production downtime due to supply delays.

Analytics platforms can visualize these KPIs to help purchasing teams vet suppliers, forecast costs, and avoid disruptions.

2. Manufacturing and Production KPIs

Once the biomass is received and tested, it is processed into CBD oil or isolate and then formulated into final products like tinctures, gummies, capsules, or topicals. At this stage, production KPIs become vital.

- Yield per Batch: Measures how much usable CBD extract is obtained from each batch of biomass. Lower yields may signal extraction inefficiencies or poor raw material quality.

- Overall Equipment Effectiveness (OEE): A composite KPI that includes equipment availability, performance, and quality. Maximizing OEE leads to higher throughput and lower costs.

- Downtime Hours per Week: Indicates equipment reliability. High downtime might require preventive maintenance or capital upgrades.

- Batch Failure Rate: Measures how often a batch doesn't meet formulation or regulatory requirements. Frequent failures waste materials and time.

- Time to Market: The time it takes for a product to move from production initiation to finished packaging. This is critical in a fast-moving and trend-driven market like CBD.

- Quality Assurance (QA) Pass Rate: Percentage of batches passing final quality checks. High QA pass rates reduce rework and recalls.

Manufacturers use analytics dashboards to monitor these KPIs in real time, enabling agile responses to issues and continuous improvement.

3. Regulatory Compliance and Testing KPIs

The CBD industry operates under scrutiny from state and federal regulators, including the USDA, FDA, and DEA. Failing to meet testing and labeling standards can lead to costly recalls, fines, and reputational damage.

- THC Compliance Rate: Tracks how many batches stay under the federally legal 0.3% THC threshold. Exceeding this limit may render a product illegal.

- Third-party Lab Turnaround Time: Delays in lab results can bottleneck product launches and shipments.

- Label Accuracy Error Rate: Ensures all ingredients, cannabinoid contents, and usage instructions are correctly stated.

- Audit Readiness Score: A composite metric derived from internal audit checklists and documentation completeness.

- Certificate of Analysis (COA) Match Rate: Measures how often the actual product contents match the third-party test results published on websites or QR codes.

Modern BI systems can link compliance KPIs to lab reports, labeling systems, and production records to create a traceable digital audit trail.

4. Inventory and Warehouse KPIs

CBD manufacturers often deal with a complex mix of perishable biomass, bulk extract, and packaged SKUs. Managing inventory efficiently is essential to avoid spoilage, shortages, and overproduction.

- Inventory Turnover Ratio: Measures how often stock is sold and replaced. High turnover indicates efficient inventory practices.

- Days of Inventory on Hand (DOH): Shows how long current stock will last based on average usage rates. Too high or low DOH can signal problems.

- Stockout Rate: Tracks the frequency of running out of critical ingredients or SKUs, leading to missed sales.

- Warehouse Picking Accuracy: Important for fulfilling customer orders without error.

- Expired Product Write-off Rate: Especially relevant for perishable tinctures or edibles with use-by dates.

StyleBI or similar tools can integrate inventory management systems and visualize trends in real time, improving demand forecasting and warehouse operations.

5. Sales and Marketing KPIs

CBD products are sold through a variety of channels—e-commerce, dispensaries, health food stores, and sometimes direct-to-consumer (DTC) subscription models. Sales KPIs help measure the effectiveness of these channels and campaigns.

- Sales Revenue by Product Line: Identifies the most and least profitable products.

- Customer Acquisition Cost (CAC): Helps determine how much marketing spend is needed to bring in a new customer.

- Conversion Rate (Online and Retail): Especially critical for digital campaigns and product landing pages.

- Repeat Purchase Rate: CBD products are often bought on a recurring basis. This KPI signals brand loyalty.

- Average Order Value (AOV): Higher AOV often correlates with successful bundling or up-selling strategies.

- Sales per Channel: Measures performance of online vs. in-store vs. wholesale distribution.

Segmenting sales analytics by region, channel, and demographic gives marketing teams deep insights into campaign ROI and product-market fit.

6. Customer Experience and Satisfaction KPIs

CBD brands that provide a superior experience and build trust are more likely to secure long-term loyalty. Customer-centric KPIs give insight into brand health.

- Net Promoter Score (NPS): A universal measure of customer loyalty and satisfaction.

- Customer Support Ticket Volume: A sudden increase may indicate product quality issues or poor communication.

- Time to Resolution: The speed at which customer issues are handled.

- Review and Rating Trends: Aggregated from platforms like Trustpilot, Google, and product pages.

- Return and Refund Rate: High rates could indicate labeling confusion, unmet expectations, or shipping damage.

Advanced analytics can use sentiment analysis to scan reviews and identify common complaints or areas for innovation.

7. Financial Performance KPIs

At the end of the day, the company must remain profitable and financially healthy. Finance teams monitor traditional KPIs but also analyze cost structures unique to the CBD market.

- Gross Margin per Product: Measures profitability after accounting for raw materials and direct labor.

- Cost of Goods Sold (COGS): Can be broken down by stage—extraction, formulation, packaging.

- EBITDA Margin: Provides a high-level snapshot of profitability excluding interest, tax, and depreciation.

- Cash Flow from Operations: Crucial in an industry where banking is still complicated due to federal regulations.

- Burn Rate (for Startups): Helps determine how long the business can survive with its current cash reserves.

Dashboards that integrate financial data with production and sales KPIs offer a 360-degree view of enterprise performance.

8. Strategic and Predictive Analytics

Beyond operational dashboards, forward-looking manufacturers in the CBD space use AI-driven analytics to gain a competitive edge.

- Demand Forecasting Models: Incorporate seasonality, marketing calendars, and historical trends to optimize production planning.

- Churn Prediction Models: Use customer behavior to flag users at risk of attrition.

- Pricing Elasticity Simulations: Predict how price changes will affect demand and profitability.

- Geo-Mapping Sales Trends: Identify regional growth opportunities or underperforming markets.

- New Product Success Score: Predicts the likelihood of a successful product launch using historical analogs and real-time data.

Platforms like StyleBI can ingest diverse data sources—from CRM systems to ERP software—and apply machine learning to uncover hidden insights.