What KPIs and Analytics Are Used on Industrial Waste Dashboards?

Managing industrial waste is essential for maintaining environmental sustainability and adhering to regulations. Keeping an eye on and controlling industrial trash may be difficult because of the variety of waste that is produced and the requirement to adhere to strict environmental regulations.

Industries use analytics and Key Performance Indicators (KPIs) on industrial waste dashboards to expedite this process. With the help of these instruments, waste management procedures may be enhanced, the environmental effect can be reduced, and compliance can be guaranteed.

The many KPIs and metrics found on industrial waste dashboards, as well as their importance, will be discussed in this article.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

KPIs for Industrial Waste Management

Waste Generation Rate

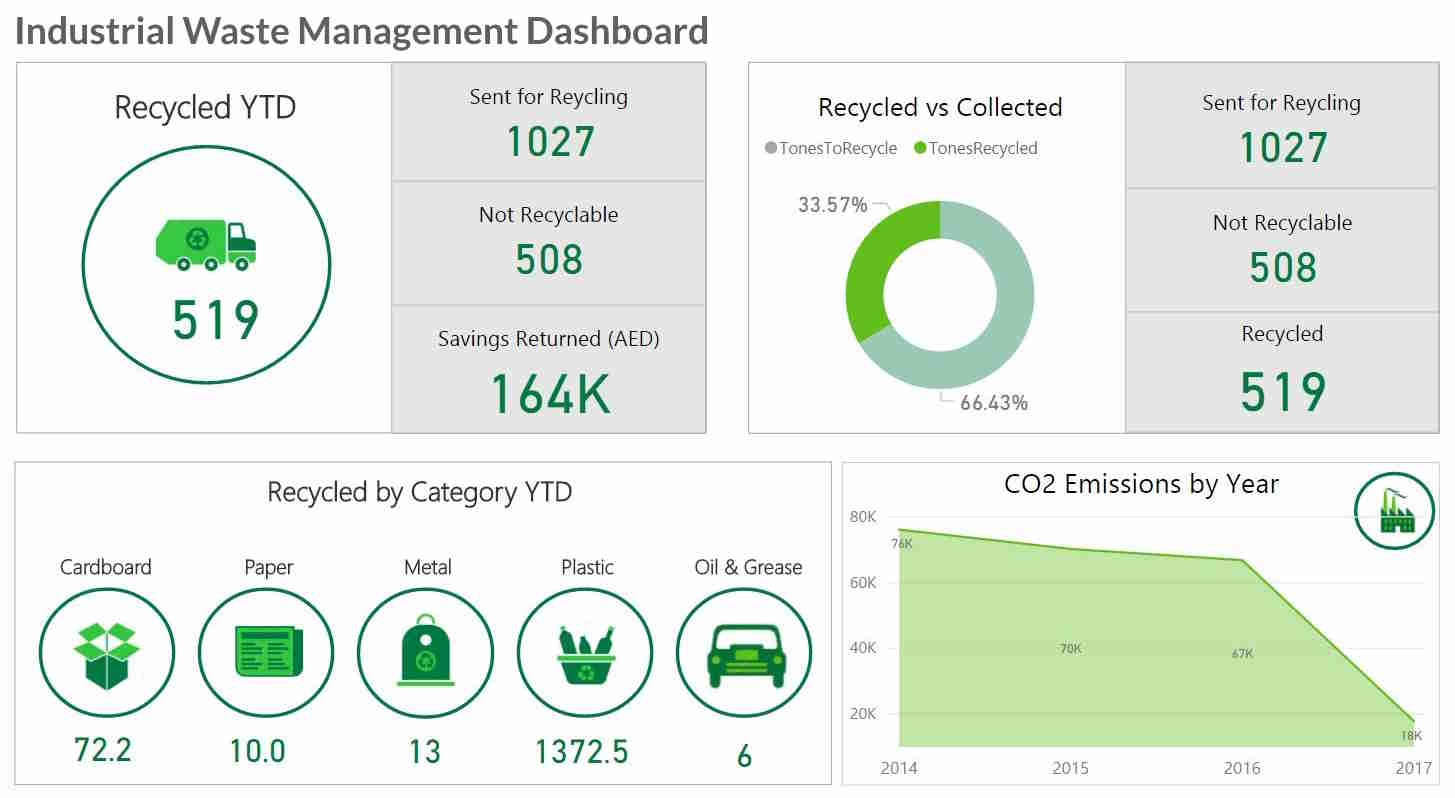

The trash production rate is a crucial key performance indicator that measures the quantity of garbage generated in a certain period of time. It facilitates resource allocation and trash reduction initiatives by assisting companies in understanding the scope of their waste output. Businesses may spot patterns, anomalies, and inefficiencies in their waste generating operations by monitoring this KPI.

Waste Composition

For disposal and recycling plans to be efficient, it is essential to understand the composition of industrial waste. KPIs for waste composition provide light on the kinds and proportions of various components in the waste stream. By using this information, companies may create focused recycling and disposal strategies that maximize resource recovery.

Waste Disposal Costs

Costs related to managing industrial waste include disposal charges, transportation costs, and expenditures related to complying with regulations. For the purpose of cost reduction and financial planning, waste disposal expenses must be closely monitored. Businesses may find ways to save costs and boost operational effectiveness by monitoring this KPI.

Waste Recycling Rate

The percentage of garbage that is recycled or reused is measured by the waste recycling rate. A waste management approach that is more sustainable is indicated by a greater recycling rate. This KPI pushes businesses to use environmentally friendly procedures, cut down on garbage that ends up in landfills, and maybe even turn a profit from recycled materials.

Compliance with Environmental Regulations

In industrial waste management, ensuring adherence to environmental rules is of utmost importance. Compliance-related KPIs assess how effectively a business complies with municipal, state, and federal waste disposal laws. Industry groups may steer clear of fines, legal problems, and brand harm by monitoring compliance KPIs.

Waste Segregation and Source Identification

Reducing trash and raising recycling rates need an understanding of the sources of waste formation and the use of efficient segregation techniques. This category of KPIs helps with focused waste reduction efforts by giving information on which areas or processes produce the most waste.

Waste Handling Efficiency

Efficiency of waste handling KPIs evaluate the effectiveness of an industrial facility's waste collection, transportation, and processing. Effective waste management minimizes the negative effects of waste management on the environment while simultaneously lowering operating expenses.

|

Learn about the top 10 features of embedded business intelligence. |

Analytics for Industrial Waste Management

Predictive Analytics

Utilizing past waste data, predictive analytics makes predictions about the creation and tendencies of trash in the future. Industries are able to make well-informed judgments on scheduling, waste management, and resource allocation by using machine learning algorithms and pattern analysis. This assists in mitigating overflows, streamlining collection routes, and averting shortages of resources.

Sustainability Metrics

Sustainability metrics examine how waste management techniques affect the environment. They calculate the energy, resource, and carbon footprint of producing, disposing of, and recycling garbage. Eco-friendly decisions and sustainability objectives are made easier for companies by using sustainable analytics.

Real-Time Monitoring

Real-time monitoring gathers information on trash levels, temperature, and other characteristics within waste containers and facilities using sensors and Internet of Things devices. After processing, this data is shown on dashboards. Industries can react quickly to problems like overfilled bins, temperature variations, or improper waste disposal by using real-time analytics.

Geospatial Analytics

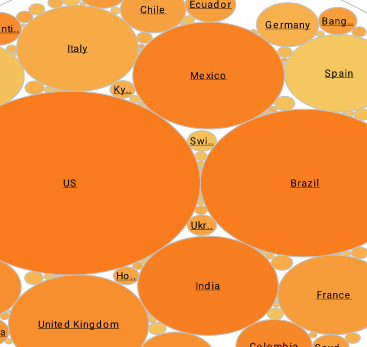

Waste data and geographic data are combined by geospatial analytics to provide location-specific insights. This is especially helpful for detecting high-waste-generation locations, streamlining garbage transportation, and optimizing waste collection routes.

|

Learn the advantages of InetSoft's small footprint BI platform. |

Root Cause Analysis

An analytical method called root cause analysis aids industry in determining the fundamental reasons behind waste-related problems. This analytics approach helps identify if issues are caused by operational inefficiencies, equipment failures, or human mistake by examining data on waste incidences.

Cost-Benefit Analysis

Decisions on waste management are evaluated financially using cost-benefit analysis. Businesses may use this analytical method to compare the possible advantages, such financial savings and reduced environmental impact, against the expenses of adopting certain waste reduction or recycling initiatives.

Performance Benchmarking

Through performance benchmarking, waste management practices within an industry are compared to rivals' or industry norms. Organizations may better understand their place in the market and pinpoint opportunities for development by analyzing this data.

|

Read the top 10 reasons for selecting InetSoft as your BI partner. |

Significance of KPIs and Analytics in Industrial Waste Management

Improved Decision-Making

KPIs and analytics provide insights derived from data that facilitate well-informed decision-making. With the use of this data, industries may minimize waste creation and its negative effects on the environment, improve resource allocation, and optimize waste management techniques.

Cost Reduction

Through the monitoring of key performance indicators pertaining to trash creation, disposal costs, and recycling rates, enterprises may detect avenues for cost reduction. Analytics that aid in cost reduction decision-making include performance benchmarking and cost-benefit analysis.

Environmental Sustainability

Industrial waste management may be made more environmentally sustainable with the use of geospatial analytics and sustainability indicators. Industries may contribute to a cleaner future by lowering their carbon footprint, energy usage, and resource use via monitoring and improving operations.

Regulatory Compliance

KPIs pertaining to environmental regulatory compliance are crucial for preventing negative legal and financial effects. These KPIs may be used by industries to make sure they adhere to all regulations and don't break any of them.

|

Learn how InetSoft's data intelligence technology is central to delivering efficient business intelligence. |

Resource Recovery

Predictive analytics and KPIs for trash composition and recycling rate assist enterprises in recovering valuable resources from their waste streams. By selling recycled products, this may not only save waste but also bring in money.

Operational Efficiency

Operational efficiency is improved via KPIs and analytics that concentrate on the effectiveness of waste management and real-time monitoring. Industries may expedite their waste management procedures by streamlining garbage collection routes and promptly addressing difficulties.