What Is a Key Performance Indicator Report?

A Key Performance Indicator (KPI) report is a document or dashboard that displays critical metrics used to evaluate the success of an organization, department, or specific business process in achieving its objectives. These reports help stakeholders quickly assess performance against predefined targets, identify trends, and make informed decisions to improve operations.

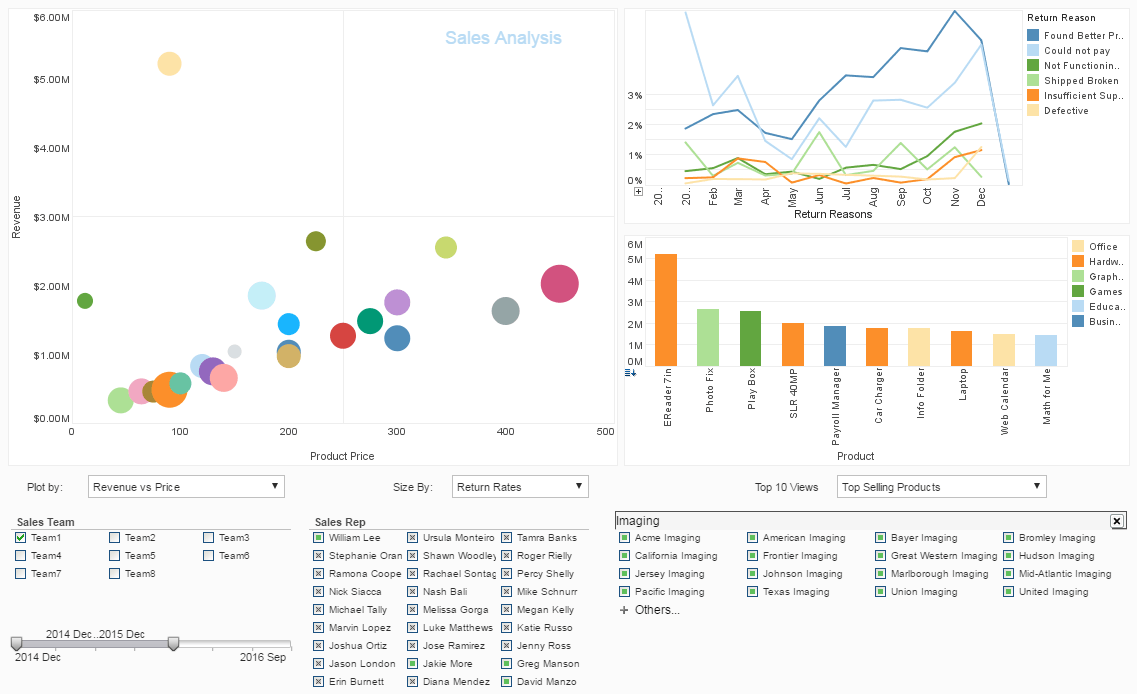

KPI reports often include data visualizations such as charts, graphs, and tables to present performance metrics clearly and concisely. They typically track metrics related to sales, customer satisfaction, operational efficiency, financial performance, and other areas relevant to the organization's goals. By regularly reviewing KPI reports, organizations can monitor progress, adjust strategies as needed, and maintain accountability across teams and departments.

Manufacturer Uses InetSoft's Serverless StyleBI App for KPI Reporting

In the precision manufacturing sector, especially in the production of vitrified bond grinding wheels, operational efficiency and quality consistency are non-negotiable. These manufacturers operate in a competitive environment, requiring precise control over material costs, production yield, downtime, and customer order fulfillment rates. One forward-thinking vitrified bond grinding wheels manufacturer adopted InetSoft’s serverless StyleBI app to modernize their KPI reporting workflows, integrating real-time insights directly into production and operational processes.

Legacy Challenges in KPI Reporting

Before adopting StyleBI, the manufacturer relied on a patchwork of manual data exports from their ERP and MES systems into spreadsheets. Weekly KPI reports were compiled manually, taking hours of IT and operations team resources. Reports often included:

- Scrap rates across different production lines

- Yield percentages per product type

- Order fulfillment timelines

- Downtime incidents and causes

- Operator efficiency tracking

However, the lack of real-time insights made it difficult for managers to adjust production plans proactively. IT teams were frequently asked to generate ad hoc reports, resulting in report delays that prevented rapid response to production bottlenecks and quality issues.

Adopting InetSoft's Serverless StyleBI App

InetSoft’s serverless StyleBI app provided a lightweight, API-first analytics solution that could be quickly integrated into the manufacturer’s cloud-based infrastructure. By leveraging StyleBI’s ability to connect to the company’s Azure SQL Database and IoT device feeds, the IT team enabled continuous data streaming into the BI layer without the overhead of managing dedicated BI servers.

The serverless architecture allowed the manufacturer to:

- Deploy dashboards and KPI reports without provisioning new virtual machines or managing underlying infrastructure

- Scale usage based on demand with cost-effective pay-per-use billing

- Securely share KPI dashboards with production managers, quality engineers, and executives across devices

Key KPIs Tracked Using StyleBI

The manufacturer defined a set of actionable KPIs aligned with operational goals:

- Overall Equipment Effectiveness (OEE): Combines availability, performance, and quality rates, allowing managers to pinpoint bottlenecks in the grinding wheel production process.

- Scrap Rate: Percentage of wheels failing quality inspection or customer acceptance, broken down by defect type and production batch.

- Cycle Time per Wheel: Tracks actual vs. planned cycle time for each product type, critical for meeting customer delivery deadlines.

- On-Time Delivery Rate: Percentage of orders shipped on or before the customer’s requested delivery date.

- Cost per Unit: Combines material, labor, and energy costs to monitor financial efficiency.

- Downtime by Cause: Categorizes unplanned downtime (machine failure, material shortage, quality hold) to drive root cause analysis.

Chart Types and Dashboards Implemented

Using StyleBI’s drag-and-drop designer, the IT team built dashboards featuring:

- Time Series Line Charts: Displaying OEE trends and scrap rates over time, with filters for production lines and shifts.

- Stacked Bar Charts: Showing downtime categorized by cause to identify persistent issues with certain machines.

- Heat Maps: Visualizing defect rates by operator and production shift, enabling targeted retraining where needed.

- Gauge Charts: For real-time cycle time vs. target cycle time, used on the shop floor for immediate feedback to operators.

- Geographic Maps: Displaying delivery performance across customer regions, useful for logistics teams to monitor delivery SLA compliance.

The dashboards are interactive, allowing managers to drill down from plant-wide views to machine-level details, or from quarterly trends to daily and hourly views.

Automated KPI Reporting with StyleBI

The IT team configured StyleBI to automate the generation of daily and weekly KPI reports:

- Reports are generated each morning with the previous day’s data automatically refreshed from SQL and IoT feeds.

- PDF and interactive HTML reports are emailed to relevant stakeholders, reducing the dependency on IT for manual report creation.

- Users can subscribe to receive notifications when specific KPIs exceed thresholds, such as scrap rates crossing the acceptable 2% limit or cycle times exceeding planned limits by 10%.

The serverless nature of StyleBI allowed these automation processes to run without additional scheduling services or virtual machine dependencies, keeping infrastructure management minimal while maintaining reliability.

Benefits Observed Post-Implementation

After rolling out StyleBI, the manufacturer experienced measurable improvements in operations and IT workflows:

- Faster Decision-Making: Managers now have real-time visibility into production performance, enabling rapid adjustments to scheduling and maintenance planning.

- Reduced Scrap: By monitoring defect types and rates daily, quality teams could identify and address root causes, reducing scrap rates by 18% in the first quarter of deployment.

- Improved On-Time Delivery: Live cycle time tracking allowed operations to reallocate resources dynamically, improving on-time delivery rates by 9%.

- IT Resource Optimization: Automated report generation and user self-service dashboards reduced the manual workload on the IT department by 60% for recurring reports.

- Cost Savings: Serverless deployment reduced the overhead costs of traditional BI infrastructure while providing elastic scalability during production peaks.

Security and Access Management

InetSoft’s StyleBI supports fine-grained, row-level security, allowing the IT team to restrict access:

- Production supervisors can view KPIs for their own lines and shifts only.

- Executives have access to plant-wide and financial KPIs.

- Quality engineers can drill down into defect data without seeing financial cost data.

Integration with Azure Active Directory allowed seamless Single Sign-On (SSO) with existing company credentials, maintaining compliance with internal security policies.

Lessons for IT Teams Considering Serverless BI

For IT leaders in manufacturing, this case highlights practical takeaways when adopting a serverless BI strategy:

- API Integration Is Key: StyleBI’s API-first design made it straightforward to integrate with existing SQL databases and IoT streams without requiring ETL rework.

- Elastic Scaling Matters: A serverless architecture allows the system to handle spikes in report generation during peak review times without overprovisioning resources.

- Focus on Self-Service: Enabling business users to interact with dashboards reduces the dependency on IT, freeing up resources for strategic projects.

- Security Must Be Planned: Fine-grained access control should be configured early to align with the organization’s data governance policies.

Future Plans: Predictive Analytics and AI Integration

The manufacturer plans to extend StyleBI’s capabilities by incorporating predictive analytics, using machine learning models to forecast:

- Machine failures based on sensor patterns

- Defect probability based on environmental and operational data

- Material usage optimization to reduce waste further

By layering AI models within the existing serverless BI dashboards, the manufacturer aims to move from reactive monitoring to predictive optimization, aligning with Industry 4.0 goals.