Supply Chain Dashboards and Reporting

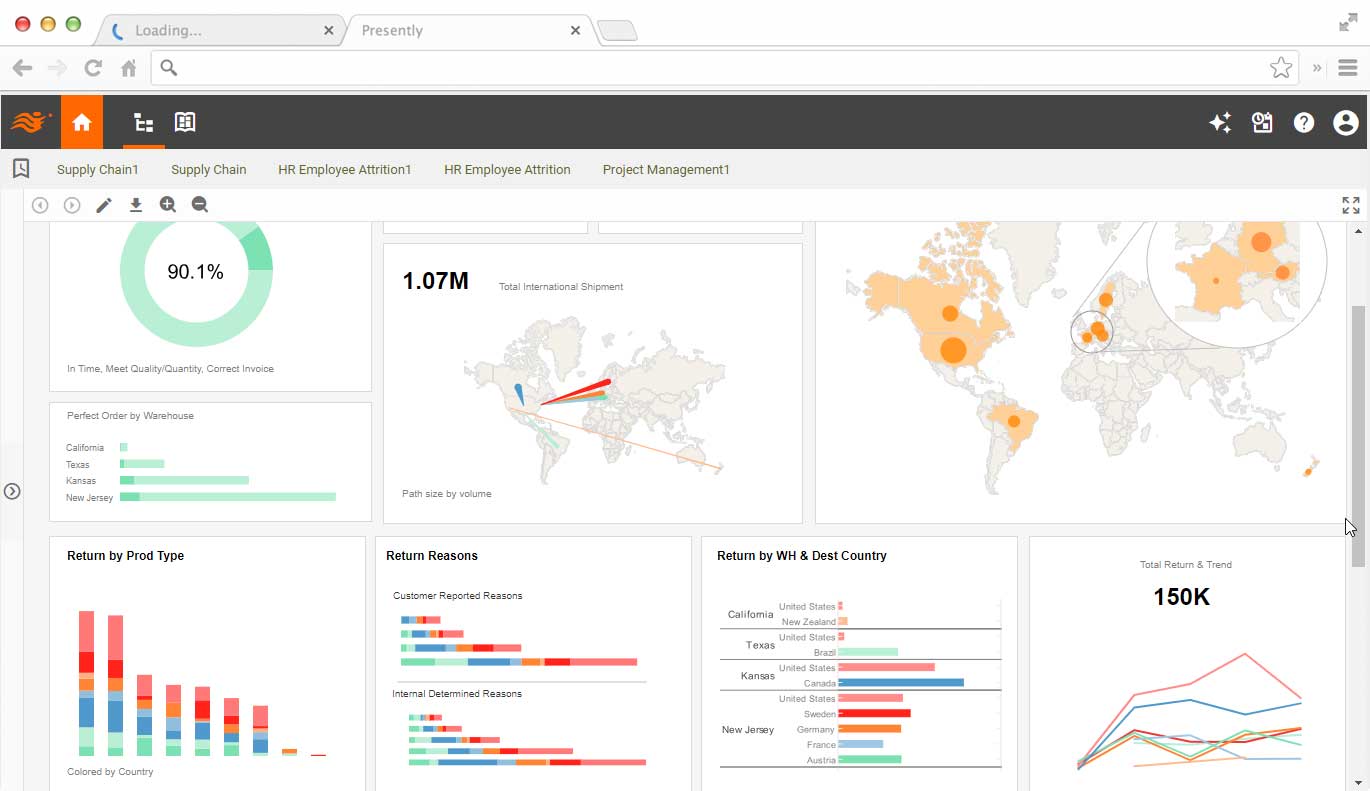

InetSoft's dashboards not only present a unified view of supply chain as intuitive visualizations, but they provide instant access to powerful business analytics through real-time interactivity and customization. Document reports, suitable for both online and offline distribution, make integrating 3rd party suppliers effortless.

Data Mashup for Complete Supply Chain Control

As supply chain extends globally, data becomes scattered in many places and in many formats. InetSoft's data mashup technology addresses this challenge head-on. As a tool for both designers and power users, it does not require heavy IT support. InetSoft's data mashup engine is integrated with visual dashboard design as a single web app. Data mashup can be immediately inspected with visualization. Likewise, visual dashboard design can quickly adjust underlying data mashups.

How a Jet Engine Component Refurbisher Switched from NetSuite to StyleBI for Supply Chain Dashboards and Reports

In the highly specialized world of jet engine component refurbishment, operational precision is paramount. Companies in this industry handle turbine blades, fuel nozzles, compressors, and other critical engine parts that must meet exacting specifications for performance and safety. Each component has a traceable history, undergoes multiple quality inspections, and requires timely delivery to aircraft maintenance providers worldwide. For a jet engine component refurbisher, the supply chain is intricate, spanning raw material suppliers, OEM certification processes, logistics providers, and internal fabrication and testing facilities. Visibility into every stage is critical to ensuring compliance, optimizing turnaround times, and maintaining profitability.

Traditionally, this refurbisher relied on NetSuite as its primary enterprise resource planning (ERP) platform. NetSuite provided a comprehensive system for financials, inventory, procurement, and basic reporting. However, as the business scaled and the complexity of its supply chain grew, limitations in NetSuite’s native reporting and dashboard capabilities became apparent. Managers found it difficult to generate real-time insights across multiple suppliers, track work-in-progress at a granular level, and anticipate potential bottlenecks before they impacted delivery schedules. The dashboards available in NetSuite were largely static, lacked customization flexibility, and offered limited integration with external data sources such as logistics tracking, OEM compliance records, and predictive maintenance systems.

Identifying the Need for Change

The decision to move from NetSuite to StyleBI was driven by several critical business requirements. First, the refurbisher needed advanced analytics that could consolidate multi-source data into actionable insights. Supply chain performance metrics, such as supplier lead times, component yield rates, quality defect trends, and order-to-delivery timelines, had to be available in real time. Second, stakeholders required highly interactive dashboards to perform root-cause analysis, identify recurring issues, and model alternative scenarios. Third, the company sought a more scalable solution that could accommodate its growth into new geographic markets while maintaining strict compliance with aviation standards.

StyleBI emerged as the ideal platform due to its flexibility, ease of integration, and ability to deliver rich, interactive dashboards. Unlike NetSuite’s built-in tools, StyleBI could pull data from multiple sources, including ERP modules, MES (Manufacturing Execution Systems), logistics tracking feeds, and quality management systems, creating a single source of truth for supply chain management. Furthermore, StyleBI’s semantic layer enabled consistent definitions of KPIs across departments, ensuring that all stakeholders operated with the same metrics and terminology.

Data Integration and Modeling

The migration process began with a detailed assessment of the existing NetSuite data model. Data architects mapped critical entities such as component inventory, work orders, supplier information, and procurement history to corresponding structures within StyleBI. This step was essential to maintain data integrity and ensure that historical records were preserved for trend analysis. StyleBI’s ETL tools allowed the refurbisher to extract, transform, and load data from NetSuite while also integrating external feeds, such as shipping updates from logistics providers and inspection results from third-party labs.

The semantic layer in StyleBI played a crucial role in unifying the supply chain data. By establishing clear relationships between suppliers, component batches, work orders, and delivery schedules, the refurbisher could create dashboards that showed end-to-end visibility. Managers could drill down from high-level KPIs — like average turnaround time per component type — to detailed views of individual supplier performance or specific quality inspection outcomes. This unified view was critical for identifying bottlenecks, mitigating risk, and making informed operational decisions.

Dashboard Design and Functionality

The next phase focused on designing dashboards tailored to different roles within the organization. Supply chain directors needed executive-level dashboards summarizing supplier reliability, inventory turnover, and order fulfillment metrics. Production supervisors required real-time visibility into work-in-progress, component status, and workstation efficiency. Quality managers needed dashboards highlighting defect rates, inspection outcomes, and non-conformance trends. By leveraging StyleBI’s drag-and-drop interface and interactive visualizations, the refurbisher could provide each role with a highly customized, actionable view of the supply chain.

One of the most valuable features was interactive filtering and drill-through capabilities. For instance, if a supply chain director noticed a spike in delayed deliveries, they could immediately drill down to see which suppliers were contributing to the issue, what components were affected, and whether there were patterns linked to specific production lines. Similarly, production supervisors could forecast bottlenecks by simulating different workload scenarios, allowing them to adjust schedules proactively rather than reactively. This level of interactivity transformed decision-making from reactive to predictive, improving overall operational efficiency.

Real-Time Monitoring and Alerts

In the jet engine component refurbishment industry, timing is critical. Delays in receiving, refurbishing, or shipping components can have cascading effects on airline maintenance schedules. StyleBI enabled the refurbisher to set up real-time monitoring and automated alerts for key supply chain events. For example, dashboards could highlight delayed shipments from critical suppliers, flag components failing inspection, or signal inventory levels dropping below predefined thresholds. These proactive notifications allowed managers to take immediate corrective action, minimizing downtime and avoiding costly disruptions.

Compliance and Traceability

Aviation components are subject to stringent regulatory requirements, including documentation of material provenance, inspection records, and refurbishment history. NetSuite provided basic tracking, but generating compliance reports often required manual data aggregation. StyleBI streamlined this process by integrating data from all relevant sources into a centralized reporting platform. Managers could generate traceability reports for specific components, showing supplier details, quality inspection outcomes, refurbishment steps, and shipment history. This capability not only improved regulatory compliance but also enhanced customer confidence by demonstrating rigorous quality control procedures.

Performance Improvements

One of the immediate benefits observed after the switch was improved system performance. Previously, generating complex reports in NetSuite could take several minutes, limiting their usefulness for operational decision-making. With StyleBI, dashboards loaded rapidly even when pulling data from multiple sources. The ability to process large datasets efficiently allowed managers to monitor the supply chain in near real-time, identify issues faster, and respond more effectively. Additionally, the simplified user interface reduced training requirements, enabling staff across departments to leverage dashboards without extensive technical expertise.

Scalability and Future Growth

As the refurbisher expanded its operations, StyleBI’s scalability became increasingly important. The platform could accommodate additional suppliers, new component types, and multiple manufacturing facilities without requiring major system redesigns. This flexibility ensured that dashboards and reports would continue to provide accurate and actionable insights even as the company’s supply chain grew in complexity. Furthermore, StyleBI’s support for embedding dashboards into other applications meant that insights could be delivered directly within operational tools, streamlining workflows and increasing adoption.

User Adoption and Change Management

Transitioning from NetSuite to StyleBI required careful change management to ensure user adoption. The refurbisher implemented a phased rollout, starting with pilot dashboards for key supply chain managers. Feedback from these early users was used to refine visualizations, adjust KPI definitions, and optimize drill-through paths. Training sessions focused on practical use cases, such as monitoring supplier performance or forecasting component delivery, helping users understand the value of the new platform. Over time, adoption spread across departments, with employees increasingly relying on StyleBI for day-to-day decision-making rather than static NetSuite reports.

Cost and ROI Considerations

From a financial perspective, the switch to StyleBI provided a clear return on investment. By improving supply chain visibility, reducing delays, and enhancing quality management, the refurbisher achieved operational efficiencies that translated directly into cost savings. The ability to consolidate multiple reporting functions into a single platform reduced the need for manual data reconciliation and redundant reporting tools. Additionally, the scalable licensing model allowed the company to extend analytics capabilities to more users without significant incremental costs, making the solution sustainable for long-term growth.

Strategic Benefits

Beyond operational improvements, StyleBI offered strategic advantages. Real-time supply chain insights allowed the company to respond to market changes more quickly, improve customer satisfaction, and differentiate itself in a competitive industry. By integrating quality data, inventory tracking, and supplier performance metrics, the firm could make informed decisions about sourcing strategies, maintenance scheduling, and capacity planning. The enhanced reporting capabilities also supported executive decision-making, enabling leadership to identify trends, anticipate risks, and prioritize investments in infrastructure or workforce development.