InetSoft's Business Intelligence Performance Management Software

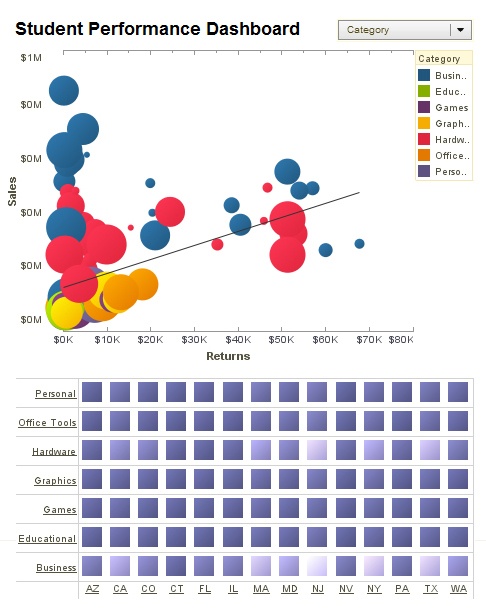

Dashboards have become the face of business intelligence performance management software. Ranging from monitoring dashboards to analytics dashboards, they are the primary view into business performance and the way to analyze why performance is deviating from target, favorably or unfavorably.

InetSoft's business intelligence performance management software is called StyleBI, and its chief advantages can be summarized as easy, agile and robust:

Easy

■ Enjoy a rapid implementation; minimum specialized IT expertise required

■ Experience a shallow learning curve for business users; only Excel-level skills needed

■ Make it easy for analysts & administrators; no SQL experience required

■ Scale up with zero-client deployment and no per-user licensing

Agile

■ Provide maximum self-service through ad hoc and visualization analysis

■ Enable self-service also at data level: end-user defined data mashup

■ Accommodate quick, formal, and experimental changes

Robust

■ Address advanced and mass needs

■ Run on a high performance, secure infrastructure

Leveraging InetSoft’s StyleBI for Performance Management in G-10 Machined Plastics Manufacturing

G-10, a high-strength, glass-epoxy laminate known for its excellent electrical insulation and mechanical properties, is widely used in industries such as aerospace, electronics, and automotive. Manufacturers of G-10 components face unique challenges, including maintaining tight tolerances, minimizing material waste, and optimizing production processes to meet stringent quality standards. To address these challenges, many manufacturers are turning to advanced business intelligence (BI) tools to gain actionable insights and streamline operations.

InetSoft's StyleBI, an open-source, cloud-native BI platform, has emerged as a powerful solution for manufacturers seeking to enhance performance management. With its robust data transformation pipeline, visualization microservices, and interactive dashboard capabilities, StyleBI enables G-10 manufacturers to monitor key performance indicators (KPIs), integrate disparate data sources, and foster real-time collaboration through integrated chat functionalities. This article explores how a G-10 machined plastics manufacturer can leverage StyleBI to manage performance, with a focus on the specific analytics and chat features that drive operational excellence.

The Role of Business Intelligence in G-10 Manufacturing

G-10 manufacturing involves complex processes, including CNC machining, material cutting, and quality assurance, all of which generate vast amounts of data. From machine performance metrics to defect rates and inventory turnover, this data holds the key to optimizing production and reducing costs. However, without a unified platform to aggregate, analyze, and visualize this data, manufacturers risk missing critical insights that could improve efficiency and competitiveness.

StyleBI addresses these challenges by providing a lightweight, scalable BI solution that integrates seamlessly with existing systems. Its open-source nature allows for customization to meet the specific needs of G-10 manufacturers, while its cloud-native architecture ensures flexibility and scalability. By deploying StyleBI, manufacturers can transform raw data into actionable intelligence, enabling proactive decision-making and continuous improvement.

Key Features of StyleBI for G-10 Manufacturers

StyleBI's core strength lies in its combination of a data transformation pipeline and a visualization engine, which together enable rapid development of analytics, dashboards, and reports. Below are the key features that make StyleBI particularly suited for G-10 manufacturing:

- Data Connectivity and Integration: StyleBI supports a wide range of data connectors, allowing manufacturers to integrate data from disparate sources such as Computerized Maintenance Management Systems (CMMS), Manufacturing Execution Systems (MES), and Enterprise Resource Planning (ERP) platforms. For a G-10 manufacturer, this means consolidating data from CNC machines, quality control systems, and inventory databases into a single platform for comprehensive analysis.

- Real-Time Monitoring and Alerts: StyleBI's real-time monitoring capabilities enable manufacturers to track critical parameters such as machine uptime, defect rates, and throughput. Automated alerts can be configured to notify managers of anomalies, such as a spike in scrap rates or equipment downtime, ensuring rapid response to potential issues.

- Interactive Dashboards: StyleBI's drag-and-drop interface allows users to create interactive dashboards tailored to specific KPIs. These dashboards can be accessed on both desktop and mobile devices, providing flexibility for production managers and shop floor operators.

- Advanced Analytics: Beyond basic reporting, StyleBI offers trend analysis, forecasting, and anomaly detection, which are crucial for predicting equipment failures and optimizing maintenance schedules.

- Role-Based Access Control: Security is paramount in manufacturing, particularly when dealing with sensitive production data. StyleBI's role-based access control ensures that only authorized personnel can access specific dashboards and data sets, protecting proprietary information.

- Chat and Collaboration Features: StyleBI includes built-in collaboration tools that allow team members to communicate directly within the platform, streamlining decision-making and issue resolution.

Performance Management with StyleBI: Key Analytics for G-10 Manufacturing

To illustrate how StyleBI enhances performance management, let's consider a hypothetical G-10 machined plastics manufacturer, Precision Composites Inc., which produces components for aerospace and electronics applications. Precision Composites leverages StyleBI to monitor and optimize its production processes through the following analytics and KPIs:

1. Yield Rate and Defect Density

Yield rate, the percentage of usable G-10 components produced compared to the total manufactured, is a critical KPI for assessing production efficiency. Defect density, which measures defects per unit area of the material, helps identify quality issues. StyleBI's dashboards allow Precision Composites to visualize yield rates across production batches, with interactive charts highlighting trends over time. For example, a line chart might reveal a recurring dip in yield every third shift, prompting further investigation into operator training or machine calibration. Anomaly detection algorithms in StyleBI can flag unusually high defect densities, triggering alerts for quality control teams to intervene.

2. Throughput and Cycle Time

Throughput measures the number of G-10 components processed per hour, while cycle time tracks the duration of specific machining steps. StyleBI's real-time dashboards display throughput metrics alongside cycle time data, enabling production managers to identify bottlenecks. For instance, a bar chart comparing cycle times across CNC machines might reveal that one machine consistently takes longer to complete a milling operation, indicating a need for maintenance or process optimization.

3. Overall Equipment Effectiveness (OEE)

OEE, a composite metric combining availability, performance, and quality, is a cornerstone of manufacturing performance management. StyleBI calculates OEE in real time by integrating data from CNC machines and quality control systems. A dashboard might display OEE as a gauge chart, with color-coded thresholds (e.g., green for >85%, yellow for 70-85%, red for <70%). Precision Composites uses this to prioritize maintenance on underperforming machines, reducing downtime and improving productivity.

4. Scrap and Rework Rates

High scrap and rework rates can significantly impact profitability in G-10 manufacturing due to the material's cost. StyleBI's data mashup engine allows Precision Composites to correlate scrap rates with variables such as machine settings, operator shifts, or raw material batches. A scatter plot might reveal that certain material suppliers are associated with higher scrap rates, informing procurement decisions.

5. Inventory Turns

Efficient inventory management is critical for minimizing costs in G-10 manufacturing, where raw materials are expensive. StyleBI's dashboards track inventory turns, showing how quickly raw materials and finished goods move through the production cycle. A stacked bar chart could break down inventory turns by product type, helping Precision Composites optimize stock levels and avoid overstocking.

6. Predictive Maintenance

StyleBI's advanced analytics capabilities enable predictive maintenance by analyzing historical equipment data to forecast potential failures. For example, by integrating sensor data from CNC machines (e.g., vibration, temperature), StyleBI can predict when a spindle is likely to fail, allowing maintenance teams to schedule repairs proactively. This reduces unplanned downtime, a common issue in G-10 manufacturing where precision machining requires consistent equipment performance.

Enhancing Collaboration with StyleBI's Chat Features

Effective communication is essential for addressing the complex challenges of G-10 manufacturing. StyleBI's built-in chat and collaboration tools enable seamless interaction among production managers, quality control teams, and shop floor operators. These features are particularly valuable in the following scenarios:

1. Real-Time Issue Resolution

When StyleBI's real-time alerts detect an issue, such as a spike in defect density, the platform allows managers to initiate a chat thread directly within the dashboard. For example, a quality control manager at Precision Composites might notice an alert indicating a high defect rate on a specific CNC machine. They can start a chat with the machine operator and maintenance team, sharing a screenshot of the defect density chart and discussing potential causes (e.g., tool wear, incorrect settings). This immediate collaboration ensures rapid resolution, minimizing production delays.

2. Cross-Functional Coordination

G-10 manufacturing involves multiple departments, including procurement, production, and quality assurance. StyleBI's chat feature enables cross-functional teams to collaborate on shared dashboards. For instance, the procurement team might notice a correlation between a specific supplier and high scrap rates. They can initiate a chat with the production manager, linking to the relevant dashboard and proposing a switch to a different supplier. This data-driven dialogue ensures alignment across departments.

3. Knowledge Sharing

StyleBI's collaboration tools also facilitate knowledge sharing by allowing users to save and share dashboard bookmarks. For example, a production supervisor might create a customized dashboard view showing OEE trends for a specific product line. They can share this view via chat with other supervisors, who can then use it as a template for their own analyses, fostering a culture of continuous improvement.

4. Audit Trails and Accountability

In a regulated industry like aerospace, maintaining audit trails is critical. StyleBI's chat feature includes timestamps and user identification, creating a record of discussions and decisions. This ensures accountability and provides documentation for compliance audits, a key consideration for G-10 manufacturers serving high-stakes industries.

Implementation and Deployment

Deploying StyleBI in a G-10 manufacturing environment is straightforward, thanks to its Docker-based architecture. Precision Composites can deploy StyleBI on Docker Desktop for local testing or scale it to cloud platforms like AWS, GCP, or Azure for enterprise-wide use. The open-source version requires a minimum of 2 cores and 4GB of RAM, making it accessible for small to medium-sized manufacturers. For advanced security needs, StyleBI Enterprise offers multi-tenant support and enhanced auditing capabilities.

To get started, Precision Composites would:

- Download the StyleBI community edition from GitHub and extract the provided .yaml file.

- Run docker compose up -d to start the server and access the application at http://localhost:8080.

- Import example datasets to explore StyleBI's capabilities, such as creating dashboards for yield rate and OEE.

- Configure data connectors to integrate with existing systems like ERP and MES.

- Customize dashboards and set up role-based access for different teams.

Benefits and Outcomes

By adopting StyleBI, Precision Composites has achieved several tangible benefits:

- Improved Efficiency: Real-time monitoring and predictive maintenance have reduced downtime by 15%, boosting throughput.

- Enhanced Quality: Anomaly detection and defect tracking have decreased scrap rates by 10%, improving profitability.

- Cost Savings: The open-source nature of StyleBI eliminates licensing costs, freeing up resources for other investments.

- Better Collaboration: Integrated chat features have streamlined communication, reducing issue resolution time by 20%.

- Scalability: The cloud-native architecture allows Precision Composites to scale analytics as production volumes grow.