Precision Manufacturing Meets Real-Time Intelligence: How a Vertical Lift Stage Manufacturer Optimized Operations with StyleBI

In the realm of high-precision motion control, vertical lift positioning stages are the unsung heroes behind industries ranging from semiconductor fabrication to medical diagnostics. For one U.S.-based manufacturer committed to tight tolerances and flawless execution, real-time insights became the missing ingredient to scaling quality and throughput. Enter InetSoft's open source StyleBI—a light-footprint, agile business intelligence solution that transformed reactive processes into proactive excellence.

Legacy Constraints: The Case for Real-Time Reporting

Prior to StyleBI's deployment, the manufacturer relied on static ERP reports generated weekly by IT staff. Production line managers operated without visibility into live order progress, maintenance flags, or shift efficiency metrics. Any deviation in KPIs—be it cycle time variance or yield dips—was only discovered post-mortem, often days after the damage was done.

To maintain competitiveness in a market dominated by speed, accuracy, and lean manufacturing, leadership pivoted toward a data democratization strategy using StyleBI’s open platform. Designed for direct integration with popular SQL data sources, StyleBI offered the modularity and real-time charting the team needed—with a much shorter implementation curve than traditional BI suites.

StyleBI Deployment: A Lightweight but Powerful Framework

Within three weeks, StyleBI was fully integrated with the company’s PostgreSQL production database and MES (Manufacturing Execution System). With a web-based drag-and-drop interface, department heads crafted dashboards autonomously, reducing report request load on IT by 85%.

Real-time reporting pipelines were established for key operational areas:

- Production Line Monitoring: Live cycle times, unit completion rates, and downtime alerts.

- Inventory Control: Real-time raw material consumption and reorder thresholds.

- QA Metrics: Yield percentages by product type, defect distribution, and inspection throughput.

- Workforce Efficiency: Individual operator throughput, overtime tracking, and cross-shift comparisons.

Key Performance Indicators (KPIs): What Gets Measured Gets Improved

Among the dozens of tracked KPIs, five emerged as the backbone of continuous improvement:

- Cycle Time Variance – Target: ±3%, Alert Threshold: ±7%

- Yield Ratio – Target: >98% finished product without defects

- Line Downtime – Target: <5% of scheduled uptime per week

- Material Waste per Unit – Target: <$0.50/unit

- Operator Efficiency Index (OEI) – Target: >1.2 units/hour

Each KPI was visualized using conditional formatting in dashboards—green for in-target, amber for warning, and red for critical deviation.

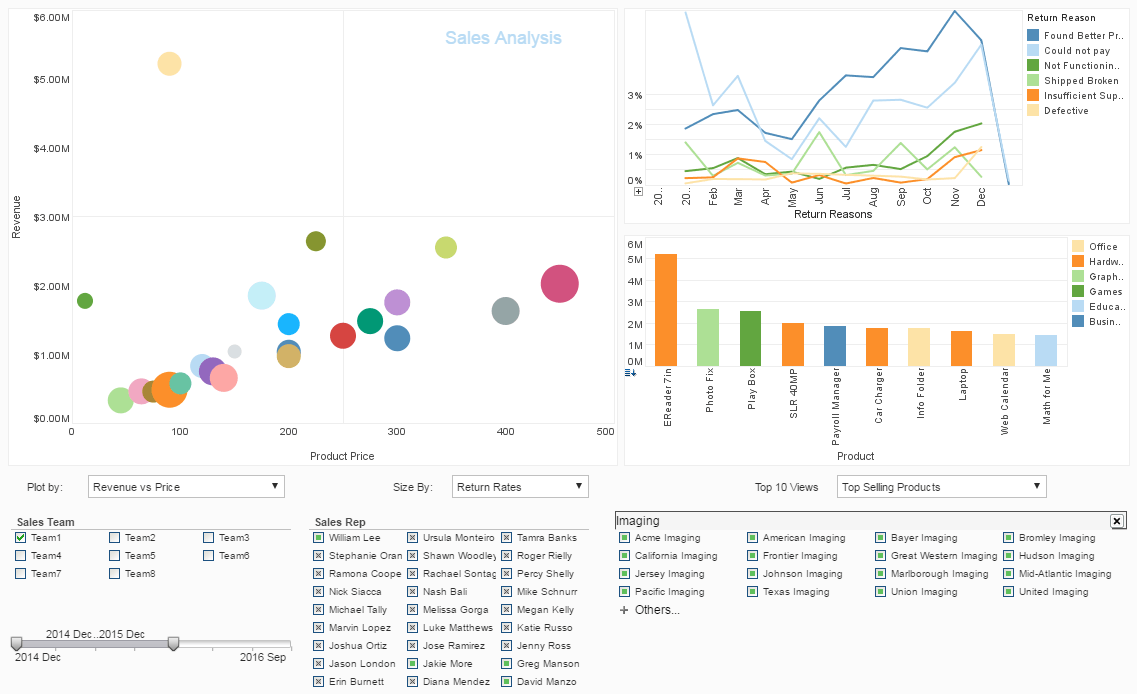

Charting Smart Decisions: Embedded Visualization Tools

StyleBI’s lightweight visualization engine allowed engineering teams to create layered chart types for deeper exploration:

- Sankey Diagrams for tracking production flow bottlenecks.

- Heat Maps highlighting defect frequency by workstation.

- Time Series Line Charts for OEI trends by week.

- Treemaps comparing SKU-level profitability and yield.

- Pareto Charts showing the most frequent defect categories.

Teams used interactive dashboards during daily standups to prioritize production adjustments. For example, when the yield for LiftStage X3 fell below 97.5%, the heat map revealed that Operator Station 12 had a 40% defect spike due to a misaligned sensor. This enabled immediate retraining and recalibration before the next production cycle.

Report Types: Real-Time Meets Role-Based Delivery

The reporting strategy emphasized contextual relevance, ensuring every stakeholder received the right insights at the right time:

- Daily Shift Summary Reports: PDF export emailed automatically to operations managers.

- Weekly KPI Digest: Interactive dashboard shared with executives.

- Live Shop Floor Monitors: TV screens displaying real-time line throughput and alerts.

- Monthly Efficiency Review: Trend analysis report presented during cross-functional review sessions.

- Ad Hoc Exploration: Engineers used StyleBI’s filterable dashboards to explore anomaly root causes.

Security and Accessibility: Open Source without Compromise

StyleBI’s open-source nature didn’t translate to security trade-offs. The IT team implemented role-based access and LDAP integration, ensuring that users could view only the dashboards and KPIs relevant to their responsibilities.

With HTML5-friendly embedding, dashboards were viewable from desktops, tablets, and shop floor terminals alike. This enabled seamless access across shifts and departments, promoting a culture of awareness and accountability.

The Impact: From Insight to Outcomes

Six months after deployment, operational metrics improved markedly:

- Yield improved from 97.2% to 99.1%

- Average cycle time deviation reduced by 60%

- Material waste per unit cut by 35%

- Downtime incidents decreased from 12/week to 4/week

- Operator throughput increased by 18% overall

By embedding BI into the heartbeat of the factory floor, the vertical lift stage manufacturer not only gained efficiency—they built resilience. Problems became patterns, patterns became predictions, and predictions informed timely interventions.