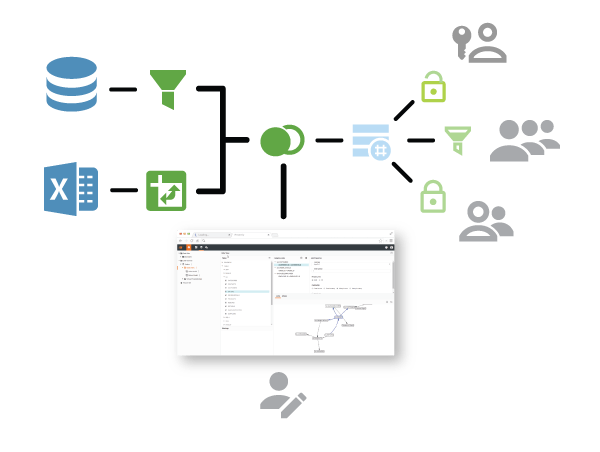

Professional Data Mashup & Governed Self-Service Mashup

BI professionals can not only easily mashup disparate data into analytic data blocks, but they can also enable controlled self-service data mashup for users via data models. Data models map prepared data to business terms and completely shield end users from underlying technical details. Data blocks' built-in visual transformation and data cleansing functions make data preparation effortless with minimal technical skills.

Models' built-in governance enforces data consistency and safeguards data processing engine integrity. As part of data governance, the data security model can secure data down to the cell level where users will only access their personalized data.

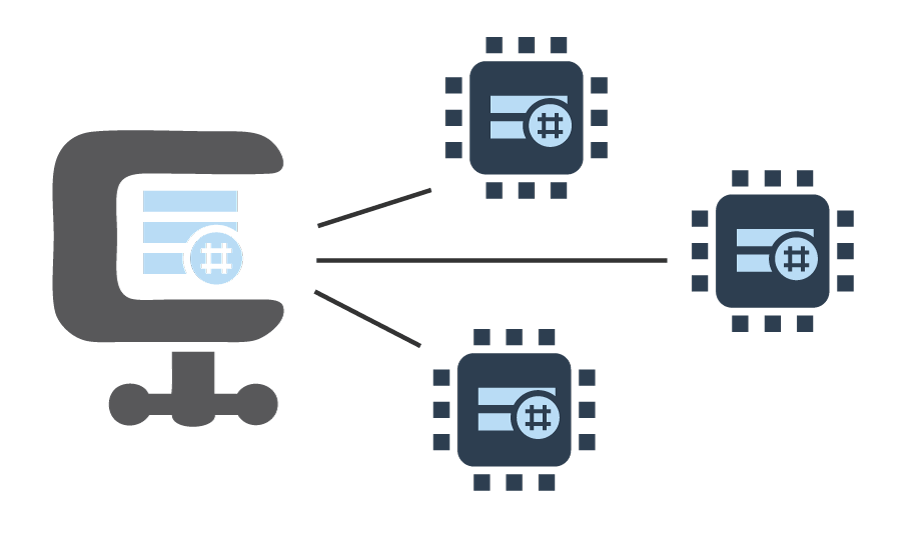

Compressed, Cluster Ready, In-Memory Cached Data

InetSoft's data mashup engine results in highly flexible data blocks. A data block can either pull in data from data sources in real time or be set up as a high performance cache. Cached data blocks are compressed and optimized for in-memory operations. User actions are served by in-memory calculations performed at lightning speeds.

How a Goniophotometer Manufacturer Switched from Workato to InetSoft for Its Enterprise Data Mashup Tool

In the precision lighting industry, data accuracy is everything. For a manufacturer specializing in goniophotometers — devices used to measure the angular distribution of light — the shift to digital transformation has not been just about automation but also about achieving deeper visibility into testing, production, and calibration data. When this niche manufacturer realized that its existing data integration platform, Workato, was becoming more of a constraint than a catalyst, the company made a bold move to adopt InetSoft as its enterprise data mashup and visualization tool. The transition fundamentally changed how the company managed its internal and customer-facing analytics, resulting in faster insights, tighter operational control, and far greater flexibility in connecting complex datasets.

The Nature of Goniophotometer Data

Goniophotometers generate large amounts of high-fidelity optical measurement data. Each test can involve hundreds of angles, multiple luminance readings, and spectral distributions captured over time. The company’s systems must correlate this data with production batch information, environmental conditions, calibration logs, and customer specifications. That data often resides across multiple silos — SQL databases for instrument logs, ERP systems for production scheduling, cloud storage for test files, and CRM platforms for customer records. Integrating all this information cohesively was critical not only for internal R&D and production optimization but also for generating customer reports that comply with ISO and CIE standards.

Initially, the company used Workato to automate data flows between its various systems. Workato’s strength lies in connecting cloud applications and executing event-driven automation. However, as the manufacturer’s needs evolved toward real-time analytics, data blending, and visual storytelling, the limitations of a pure integration platform became evident. Workato could move data efficiently, but it wasn’t designed to perform deep transformations, aggregations, or visual mashups that engineers and quality analysts required. The IT team began to search for a platform that could not only integrate data but also empower users to interpret it directly through dashboards and analytics.

Limitations Encountered with Workato

While Workato was helpful in automating repetitive tasks such as syncing calibration logs to the ERP or notifying quality teams when test data exceeded tolerance thresholds, several operational pain points became increasingly apparent:

- Complex Transformation Requirements: Goniophotometric data involves large numerical matrices that need multi-level transformations — angular normalization, unit conversions, and calibration curve fitting. Workato’s formula framework proved cumbersome for these advanced transformations.

- Lack of Unified View: Data integrations built with Workato fed into separate databases and spreadsheets, requiring additional manual compilation to visualize trends or deviations across instruments.

- Limited Visualization Capability: Workato focuses on automation rather than analytics. Engineers had to export data to third-party visualization tools like Tableau, which introduced delays and data synchronization issues.

- Growing Cost Over Time: As integrations scaled, so did the number of recipes and connectors. Licensing costs became disproportionately high for the volume of data processed daily.

In essence, Workato solved the data movement problem but not the data understanding problem. For a company that depended on precision analytics, that gap was significant. The leadership team wanted an end-to-end platform that could integrate, transform, and visualize data in one continuous flow — without multiple tools stitched together.

Why InetSoft Was Selected

InetSoft entered the picture during a proof-of-concept phase. The manufacturer evaluated several alternatives — including Talend, Pentaho, and Domo — but InetSoft’s unique combination of data mashup and embedded analytics stood out. Its Style Intelligence and Style Scope products offered an integrated environment where IT teams could connect diverse data sources and business users could explore data through intuitive dashboards.

Three primary factors drove the decision:

- Integrated Mashup Layer: InetSoft allows users to visually combine data from multiple structured and unstructured sources, apply complex transformations, and expose those results directly to dashboards. This eliminated the need for external ETL scripts or separate integration platforms.

- Self-Service Analytics: Engineers could build custom dashboards for optical testing or calibration validation without waiting for IT. This empowered departments to analyze results in near real time.

- Lightweight Deployment: InetSoft’s web-based architecture fit perfectly within the manufacturer’s hybrid infrastructure, allowing both on-premise and cloud data to coexist seamlessly.

InetSoft’s pricing model also proved more favorable for a mid-sized manufacturer. Unlike Workato’s usage-based costs that rose with each integration and data transaction, InetSoft offered a predictable licensing structure with scalability options. This was appealing to finance teams looking for long-term budget stability.

Implementation and Transition Process

The switch was not instantaneous. The manufacturer’s IT team spent about four months migrating critical data workflows from Workato to InetSoft. They began by identifying key integration points — primarily between the goniophotometer test database, ERP, and customer report systems. The new data mashup layer was designed to connect all these sources through InetSoft’s connectors and create unified datasets for analytics.

InetSoft’s data transformation functions were particularly valuable. Engineers could now apply complex formulae — such as calculating luminous intensity distributions or efficiency ratios — within the mashup interface itself. Once the data was prepared, dashboards were developed for various stakeholders:

- Production Dashboards: Visualized daily throughput, test results, and failure rates per instrument type.

- Quality Control Dashboards: Mapped deviations from standard photometric curves and linked them to calibration history.

- Customer Service Dashboards: Generated performance summaries for clients, replacing static PDF reports with interactive visual dashboards accessible through the customer portal.

InetSoft’s embedding capabilities allowed these dashboards to appear directly within the manufacturer’s internal and client-facing web applications, maintaining consistent branding and single sign-on authentication. That integration was far smoother than the previous data exports and visualization routines that depended on multiple systems.

Benefits Achieved After Switching

The shift from Workato to InetSoft delivered several tangible improvements across the organization:

- End-to-End Data Flow: Instead of moving data between applications and storing intermediate results, InetSoft allowed direct visualization of live data streams from sensors and databases.

- Reduced System Overhead: With fewer platforms to manage, IT maintenance dropped by nearly 30%. All analytics, mashups, and visualizations were contained within a single solution.

- Real-Time Insights: Engineers could identify calibration drifts or measurement inconsistencies immediately, rather than after scheduled data exports.

- Improved Collaboration: Shared dashboards and role-based permissions meant production, quality, and customer service teams were always working from the same data version.

- Lower Licensing Costs: Annual software expenses decreased due to InetSoft’s more predictable pricing and reduced dependency on third-party visualization tools.

These benefits compounded quickly. The engineering team reported faster root cause analysis during production anomalies, while management gained access to KPI dashboards summarizing yield rates, compliance percentages, and instrument uptime. Customers also appreciated the new interactive reports that visualized their luminaires’ photometric performance — strengthening client relationships and trust.

Technical Highlights

InetSoft’s data mashup architecture introduced features that Workato simply could not support, including:

- Real-Time Query Federation: Ability to join data from the company’s on-premise MySQL measurement database with cloud-based ERP and CRM systems on demand.

- Advanced Transformations: Use of inline calculated fields and dynamic formulas for luminous intensity and flux calculations without external scripting.

- Embedded Visualization API: REST and JavaScript APIs to embed dashboards in custom web interfaces while maintaining brand consistency.

- Role-Based Access: Fine-grained control ensuring that technicians, engineers, and executives viewed only relevant slices of data.

These capabilities allowed the goniophotometer manufacturer to unify its operational and analytical landscapes for the first time. What once took hours of manual data processing and visualization became instantaneous, interactive, and actionable.

Strategic Implications for the Future

With InetSoft as the foundation for enterprise data mashups, the manufacturer is now exploring predictive analytics and machine learning integration. The company plans to model failure probabilities for lamp and luminaire samples, forecast calibration intervals, and optimize testing schedules based on historical throughput. InetSoft’s open integration model supports such advanced extensions, connecting easily with Python-based AI models or external analytics engines.

Moreover, the firm is using InetSoft to build a consolidated data warehouse that not only serves internal needs but could eventually support industry benchmarking. By aggregating anonymized photometric test results, they aim to provide insights to lighting designers, certification labs, and other optical equipment makers — positioning themselves as a knowledge leader as well as a manufacturer.