ROI from a Business Intelligence Software Purchase

This is the continuation of the transcript on "How Business Intelligence Pays Back Return on Investment." The speaker is Jessica Little.

That's an incredible ROI from a business intelligence software purchase. And then they give some of that money back, not all of it, but some of the money back to the people who make it happen which are the guys that are driving the trains. Now this is an interesting kind of use of BI sensing and then analyzing and then saving and then changing process and then rewarding the people who were doing it. Those are the kinds of things that will drive BI to become pervasive.

Over the last 10 to 15 years we’ve gone from that data warehouse infrastructure to, hey, look at us we’re reporting, isn't that fun to what can we report faster? Could we be predictive? Could we get out ahead of it instead of being reactive? Could we know what's going to happen in our businesses in advance so that we can make decisions in a closer to real time environment? All of these things are adding value to the systems that are already there, and adding value by bringing more people onto it.

There are some things going on in this world of BI and data warehousing which are very interesting. Moving the whole concept of scoring or fraud management, down into the database is changing the way the technology is being used. This gets rid of 75% of the data management problems that the analyst and the data miners have to do.

Dynamic Reporting

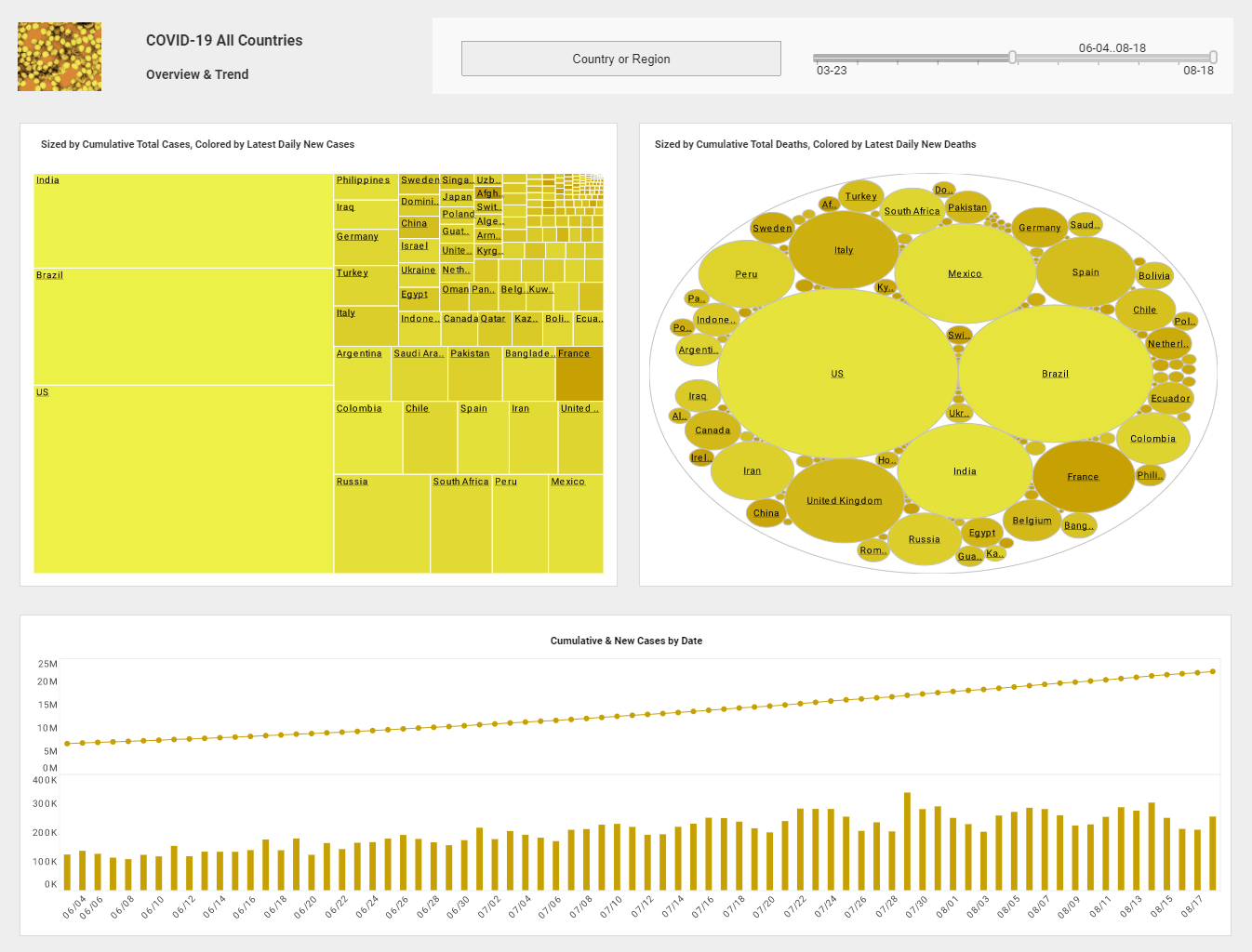

Reports are not static anymore. They are not reports anymore. They are actually dynamic, and they are dynamic even in your email. Now business intelligence vendors are starting to do some of those kinds of things, not just dashboards but creative kinds of dynamic things, dynamic heat maps, all sorts of things coming on in BI with the visualization technologies.

When you put that on an iPhone you now have an executive being able to make decisions with real data, quality data, integrated data across his business, and he’s not just looking at a report. He can take real action to make money. They’re watching their business instead of it having it report it to them. That's a big difference.

This lets you talk about trying to really manage relationships not from a product or a revenue base from a long term relationship beyond this quarter or this year. And at the same time you can strive to provide better and better service at a lower price at the same time. For direct marketing, it means stopping sending irrelevant, untimely, non-sophisticated generic garbage through either the post mail, the email or even on other kinds of mechanisms like the phones.

And the relevancy issue that these managers have come to at these companies has created an overwhelming advantage for them in their markets, and I see them doing what we talk about as a vision in a strategy in real life. It not only warms my heart that they are excelling, but it warms my heart that their customers are made happier.

ROI Achieved by an Emulsion Explosives Manufacturer Switching from Looker Studio to StyleBI

Emax Blasting Solutions, a mid-sized manufacturer in the emulsion explosives industry, recently completed a transformative shift in its business intelligence strategy. The company had relied on Looker Studio for several years to track production efficiency, safety metrics, and supply chain performance. While Looker Studio provided a modern interface and basic visualization capabilities, it presented limitations as the company expanded operations and sought deeper insights from its complex manufacturing data. In response, Emax migrated to the open-source StyleBI platform, and the results in terms of return on investment (ROI) have been significant.

Challenges with Looker Studio

Looker Studio had initially served Emax well by offering easy-to-build dashboards and integration with their existing ERP and production systems. However, as the company’s operations scaled, several challenges emerged. First, Looker Studio’s performance became a bottleneck when querying large datasets from multiple sources. Emax’s emulsion explosives manufacturing process generates high volumes of data, including temperature and pressure readings from mixing units, batch quality metrics, inventory movements, and safety incident logs. Pulling this data into Looker Studio often resulted in slow dashboard updates and lag, reducing its utility for real-time decision-making.

Another limitation was customization. While Looker Studio allowed basic dashboard creation, complex metrics and multi-source mashups required advanced SQL knowledge or additional technical resources. The company frequently needed to modify dashboards to accommodate new KPIs, such as calculating yield variance by production line or analyzing defect patterns relative to raw material quality. Each modification required IT intervention, delaying decision-making and adding operational costs.

Additionally, Looker Studio’s licensing and cloud infrastructure costs increased as Emax expanded its reporting needs. While the platform provided value, the company found it challenging to scale analytics without incurring proportional increases in subscription fees and cloud storage costs. This prompted the leadership to explore alternative BI solutions that could deliver greater flexibility and lower total cost of ownership.

Why StyleBI Was Selected

StyleBI, an open-source BI solution, offered Emax the flexibility and cost-efficiency that the company required. Its serverless architecture allowed direct connections to multiple data sources, including the ERP system, production sensors, and supply chain databases, without relying on pre-aggregated datasets. This capability enabled the company to build dashboards that reflected real-time operations, from batch mixing efficiency to shipment tracking.

Another factor in choosing StyleBI was its intuitive drag-and-drop interface. Non-technical managers could create and modify dashboards without needing advanced SQL skills, reducing dependency on IT staff and accelerating decision-making. StyleBI’s open-source nature also allowed Emax to customize the platform extensively, integrating specialized calculations for explosive yield analysis, safety compliance metrics, and equipment maintenance tracking.

The total cost of ownership was a decisive factor. Unlike Looker Studio, StyleBI required no recurring subscription fees, and the open-source model enabled the company to deploy the platform on existing on-premise infrastructure. This eliminated cloud hosting costs and allowed IT to focus on enhancing analytical capabilities rather than managing subscriptions.

Implementation and Integration

Emax adopted a phased approach to implement StyleBI. Initially, the company replicated critical Looker Studio dashboards in StyleBI, ensuring parity in reporting accuracy and consistency. Key dashboards included production efficiency reports, defect tracking, and inventory utilization. The IT team worked closely with production managers to validate the new dashboards and refine calculations to reflect the unique operational parameters of emulsion explosives manufacturing.

Once core dashboards were validated, Emax expanded into advanced analytics. StyleBI’s mashup engine allowed integration of multiple data sources, including IoT sensor readings, supplier quality metrics, and shipment data. Managers could now visualize the relationships between raw material quality, production process deviations, and product yield in real time. Additionally, StyleBI’s automated scheduling and alert features enabled proactive monitoring of equipment maintenance and safety compliance, significantly reducing risk exposure.

Quantifying ROI

The switch to StyleBI generated measurable ROI across several dimensions. First, the company realized a substantial reduction in operational costs. By eliminating Looker Studio subscription fees and cloud hosting expenses, Emax reduced its annual BI expenditure by approximately 40%. IT staff were able to redirect their efforts from dashboard maintenance to process improvement initiatives, further increasing organizational efficiency.

Operational efficiency gains were also significant. Real-time monitoring of batch production and equipment utilization allowed managers to identify bottlenecks and optimize production schedules. Within six months of implementation, production throughput increased by 12%, and yield consistency improved by 15%, directly impacting revenue and reducing waste. The ability to visualize defect patterns relative to raw materials and process parameters also contributed to faster corrective actions, reducing scrap and rework costs.

Safety improvements translated into both cost savings and risk mitigation. Emulsion explosives manufacturing is inherently high-risk, and StyleBI dashboards provided timely alerts for deviations in mixing conditions, equipment anomalies, and safety incidents. The proactive monitoring system helped prevent potential accidents, reducing both liability and insurance premiums.

Decision-making speed improved as well. Managers no longer had to wait for static reports or request IT interventions for custom dashboards. Access to real-time KPIs enabled faster adjustments to production schedules, raw material orders, and shipment planning. This responsiveness improved client satisfaction, reduced delivery delays, and strengthened Emax’s competitive position in the market.

Strategic Benefits Beyond ROI

In addition to quantifiable financial benefits, the adoption of StyleBI enhanced Emax’s strategic capabilities. The platform allowed the company to experiment with predictive analytics, forecasting batch quality and maintenance needs before issues occurred. Managers could test different operational scenarios, optimizing resource allocation and reducing downtime. This forward-looking capability was not feasible with the previous BI system.

The cultural shift within the organization was also noteworthy. Employees across production, quality, and supply chain teams became more data-driven, leveraging dashboards to make informed decisions and improve collaboration. By democratizing access to analytics, StyleBI fostered a culture of continuous improvement that extended beyond cost savings and efficiency gains.