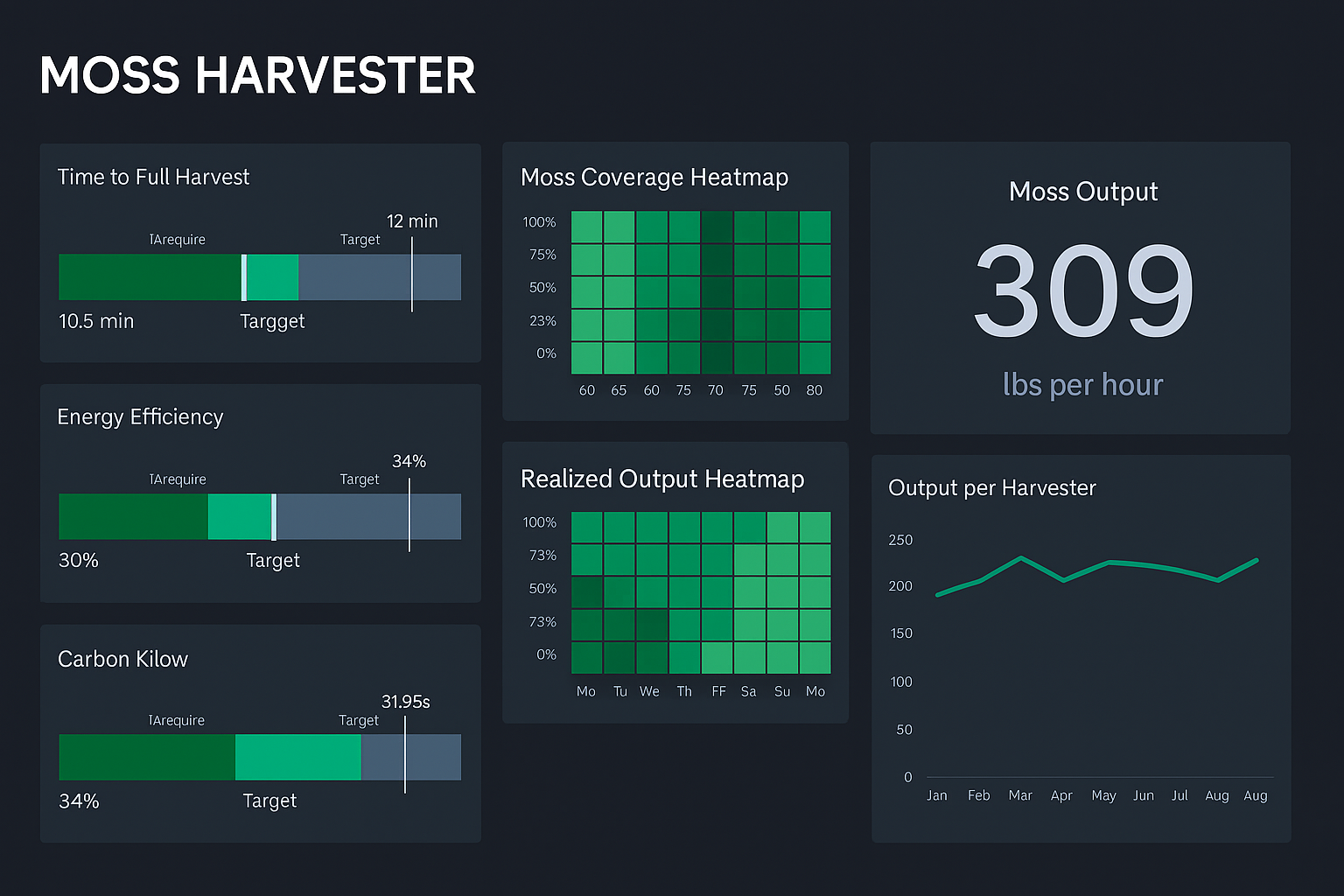

Moss Harvester Moves from Caspio to Open-Source StyleBI for Business Metrics Dashboards

A boutique moss harvesting operation made a deliberate shift from a cloud low-code platform (Caspio) to an open-source Business Intelligence solution (StyleBI) to gain control, reduce recurring costs, and empower field crews and commercial teams with richer analytics.

The move responded to operational realities unique to ecological harvesting—patch-level traceability, seasonal yield variability, fragile supply chains, and stringent sustainability reporting—while recognizing that analytics and custom apps are core to competitive advantage rather than a commoditized utility.

Industry Background: Why Data Matters for Moss Harvesting

Moss harvesting blends delicate ecosystem stewardship with logistical complexity. Harvesting crews collect from multiple wetland patches, each with different moisture profiles, regrowth intervals, and regulatory restrictions. Post-harvest processing includes cleaning, grading, and drying, and product grades command variance in price depending on species and sterility. Sales channels stretch from florists and terrarium suppliers to ecological restoration projects. Data flows across manual harvest logs, GPS traces, moisture sensors, inventory spreadsheets, compliance paperwork, and invoices—creating a need for mashups that turn fragmented records into operationally actionable metrics.

Pain Points with Caspio

Caspio provided a quick path to digitize harvest tickets and store structured records, yet several limitations emerged as scale and analytic demands grew. Custom visual analytics were restricted by template constraints and the low-code abstraction; complex joins across time-series sensor data and invoices required workarounds or exports. Cost predictability became a concern as user counts and API calls rose with seasonal demand; license and consumption fees gradually exceeded what a small producer wanted to pay. Offline field use was clunky—workarounds were built to cache data on tablets and reconcile later—which introduced reconciliation errors. Finally, embedding analytics into the commercial website and point-of-sale systems proved nontrivial under Caspio’s architecture, hampering opportunities to display real-time inventory and product quality to buyers.

Decision Criteria and Why Open-Source StyleBI Won

The selection criteria emphasized four priorities: full control over data and deployment, low marginal cost for additional users and sites, strong mashup capabilities to blend sensor, lab, and financial data, and the ability to embed and brand dashboards for customers. Open-source StyleBI appealed because it offered a self-hosted option, extensible connectors, and embeddability without per-seat pricing. The open-source model also enabled deeper customization—important for unique visualizations like graded moss bank maps, traceability timelines, and ecological impact reports. The ability to inspect and modify source code reduced vendor-lock concerns and promised futureproofing for export formats demanded by conservation partners.

Migration Plan: Phased, Practical, and Low Risk

The migration followed a pragmatic phased strategy. Phase one secured parity: recreate key harvest workflows and dashboards in StyleBI while keeping Caspio as the canonical capture system. Phase two introduced hybrid mashups—linking Caspio exports and direct sensor streams into StyleBI visualizations—so that engineers could validate metrics without disrupting field capture. Phase three cutover write paths to the new data API and retired redundant Caspio apps after a parallel run. Each phase included acceptance criteria: data parity checks, user acceptance testing by harvest crews, and performance thresholds for real-time dashboards. A three-month parallel period provided confidence that operations would remain uninterrupted.

Data Architecture Changes and Integrations

The architectural approach shifted from a single vendor’s closed stack to a hybrid, modular pipeline. Harvest logs and historical records were ported to a lightweight PostgreSQL instance, while time-series moisture and temperature streams were routed to a time-series database optimized for analytics queries. A small ETL layer (Cron jobs and lightweight Python scripts) normalized species codes, standardized units of measure, and performed deduplication. StyleBI connected to these data stores using its native connectors and REST endpoints, enabling direct mashups without expensive intermediate storage. For legacy systems that only exported CSV, an automated ingestion process validated and normalized files before insertion.

User Experience: Field-Ready Dashboards and Templates

Design focused on mobile-first dashboards for harvest crews and tablet-optimized views for processing operators. Key screens included a patch-status dashboard showing last harvest date, regrowth index, and permitted harvest window; a batch processing view tracking drying times, sterility checks, and grade assignments; and a commercial dashboard displaying inventory available by grade with embedded shipping ETA. Prebuilt templates accelerated adoption—templates for harvest ticket review, environmental compliance reporting, and customer quality certificates were offered so nontechnical users could add new visualizations without coding.

Governance, Security, and Compliance

Self-hosting made governance a central design consideration. Role-based access controls were implemented so that harvest crews could submit and edit tickets for assigned patches, processing technicians could amend batch grades, and commercial staff could view sales metrics without editing privileges. Audit logging tracked edits to traceability records and supported regulator inquiries. Data backups and an offsite replica ensured resilience, while TLS and firewall rules protected externally exposed endpoints. The open-source stack enabled integration with existing corporate single-sign-on, simplifying onboarding and revocation for seasonal contractors.

Operational Benefits Realized

The shift unlocked measurable operational improvements. Reporting latency shrank from daily exports to near-real-time dashboards, enabling immediate decisions—such as delaying harvest in overly wet conditions to maintain sterility or reallocating crews when a high-grade batch was discovered. Cost savings emerged from eliminating per-user and per-API consumption fees. Empowerment of process engineers to perform ad-hoc queries reduced backlog for IT and eliminated awkward export-and-reconcile cycles. Embedding inventory and quality dashboards into the online ordering portal improved buyer trust and reduced pre-sale inquiries.

Challenges and Mitigation Strategies

Transitioning from a managed low-code product to an open-source stack introduced challenges. Operational responsibility shifted to internal IT for patching, backups, and uptime monitoring. That overhead was mitigated by containerization and automated deployment scripts which simplified updates, and by outsourcing occasional maintenance to a trusted contractor on a fixed-price retainer rather than per-incident fees. Data quality surfaced as a recurring issue—manual harvest logs required validation rules to prevent inconsistent species codes and unit mistakes. Lightweight validation at the point of capture and daily reconciliation scripts reduced errors significantly. Finally, some stakeholders initially distrusted custom dashboards; this was addressed through side-by-side comparisons and user training sessions demonstrating parity and improvements.

People and Change Management

Adoption relied on pragmatic change management. Champions were recruited among processing supervisors and commercial leads to pilot dashboards and provide feedback. Training combined short, role-focused bite-sized sessions with online quick-start guides and a visual template library. Incentives encouraged adoption: faster batch closure times were tracked and recognized, and commercial teams received access to a customer-facing dashboard to proactively answer buyer questions. Documentation of data definitions—what constitutes a grade A versus grade B batch, how moisture is measured—was emphasized to prevent misinterpretation.

KPIs and Monitoring

Key performance indicators were redefined to align analytics with business impact. Leading indicators included harvest yield per patch per week, regrowth index trends, and drying throughput. Operational KPIs tracked time from harvest to dispatch, percentage of batches meeting sterility thresholds, and inventory turnover by grade. Financial metrics such as revenue per kilogram by grade and margin per batch tied analytics back to commercial outcomes. Dashboards were instrumented to alert when critical thresholds were breached—such as drying time anomalies that correlated with increased rework rates—enabling rapid remediation.

Lessons and Recommendations for Similar Small Producers

First, prioritize the highest-value data flows: traceability, quality, and inventory. Second, adopt a hybrid approach during migration—keep capture stable while moving analytics so that harvest operations are never disrupted. Third, invest in lightweight automation for validation at capture to prevent garbage-in problems. Fourth, favor embeddability: analytics that surface in sales and customer portals multiply value by improving transparency with buyers. Lastly, accept that self-hosting brings responsibilities; automate deployments, backups, and monitoring from day one to maintain low operational overhead.

Long-Term Outlook and Strategic Value

In the long term, the switch positions the harvester to exploit advanced analytics: predictive models that forecast regrowth windows based on weather and soil moisture, optimization models for crew routing to minimize footprint disturbance, and dynamic pricing tied to inventory grade and seasonality. The open-source approach provides flexibility to add domain-specific modules, integrate machine vision for grading, or expose APIs to marketplaces and conservation partners. The change reframes analytics from an operational cost to a strategic capability that enhances sustainability credentials, operational efficiency, and customer experience.

Moving from Caspio to an open-source StyleBI stack was not solely a technical migration; it represented a redefinition of ownership over data and the insights derived from it. For a boutique moss harvester reliant on traceability, quality, and trust, that redefinition paid dividends—operationally, commercially, and ethically—while establishing a foundation for future innovation.