InetSoft's StyleBI: More than a BI Tool, A BI Platform

InetSoft offers a business intelligence tool for dashboards, analysis, and reporting that is easy, agile, and robust. InetSoft's flagship product, StyleBI™, goes beyond traditional business intelligence tools by providing a complete BI software platform which includes fine-grained security and administration for accessing diverse data sources.

In addition to pixel-perfect report publication, this advanced BI platform offers powerful yet easy-to-use Web-based applications for dashboard creation and interactive visual analysis. InetSoft's business intelligence tools maximizes self-service and empowers end-users.

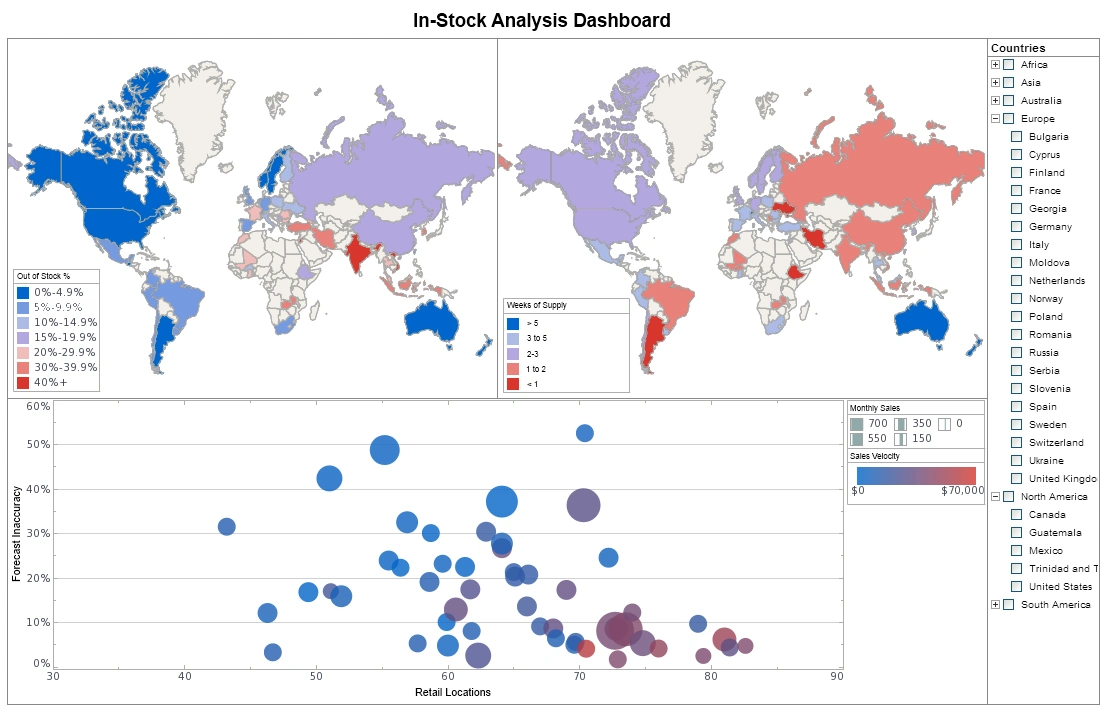

An Example of a BI Dashboard

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting.

InetSoft's patent pending Data Block™ technology enables productive reuse of queries and a unique capability for end-user defined data mashup. This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

Leveraging InetSoft's StyleBI for Business Intelligence Dashboards in Protective Clothing Manufacturing

Protective clothing manufacturing is a complex industry, encompassing products like flame-resistant garments, chemical-resistant suits, and medical-grade protective gear. Manufacturers face challenges such as fluctuating raw material costs, stringent safety regulations, and the need for rapid response to market demands (e.g., PPE surges during pandemics). Data scientists in this sector work with diverse datasets, including production metrics, supply chain logistics, quality control parameters, and sales performance.

Key performance indicators (KPIs) in this industry include:

-

Yield Rate: Percentage of usable products compared to total output, critical for assessing production efficiency.

-

Defect Density: Number of defects per unit, essential for quality control.

-

Throughput and Cycle Time: Measures of production speed and process efficiency.

-

Inventory Turns: Efficiency of raw material and finished goods utilization.

-

Compliance Metrics: Adherence to safety and regulatory standards.

To manage these metrics effectively, manufacturers need BI tools that offer flexibility, scalability, and ease of use. InetSoft's StyleBI, with its data mashup capabilities and interactive dashboarding, is well-suited to address these needs.

Why StyleBI?

InetSoft's StyleBI is a 100% web-based BI platform designed for agility and self-service analytics. Its key features include:

-

Data Mashup Engine: Allows integration of diverse data sources (e.g., SQL databases, ERP systems, spreadsheets, and cloud-based platforms like Salesforce or Google Analytics) into a unified data block for analysis.

-

Drag-and-Drop Designer: Enables non-technical users to create dashboards, while offering advanced customization for data scientists.

-

Interactive Visualizations: Supports charts, tables, heatmaps, and gauges for dynamic data exploration.

-

Small Footprint: Java-based architecture ensures minimal system resource usage, ideal for scalability.

-

Self-Service Analytics: Empowers business users to explore data without heavy reliance on IT, while data scientists can leverage advanced scripting for complex transformations.

StyleBI's compatibility with open-source big data solutions like Hadoop and proprietary systems like Oracle makes it versatile for manufacturing environments. Its cloud-ready deployment options further enhance accessibility for global operations.

Implementing StyleBI in Protective Clothing Manufacturing

Step 1: Data Integration and Preparation

The first step in deploying StyleBI is to integrate disparate data sources. A protective clothing manufacturer might pull data from:

-

ERP Systems: For production schedules, inventory levels, and procurement data.

-

Quality Control Systems: For defect tracking and compliance records.

-

Supply Chain Management Tools: For logistics and supplier performance metrics.

-

Sales and CRM Platforms: For demand forecasting and customer insights.

StyleBI's data mashup engine simplifies this process by generating native queries and API calls to create analytic-ready data blocks. For example, a data scientist can combine ERP data on raw material costs with quality control data on defect rates to analyze cost-quality trade-offs. The platform's worksheet interface allows drag-and-drop query design, reducing the need for manual SQL coding.

For advanced transformations, data scientists can apply formulas or Java-based expressions within StyleBI's worksheet. For instance, calculating defect density might involve aggregating defect counts across production batches and normalizing by output volume. The platform's caching capabilities ensure high performance, even with large datasets, by enabling incremental updates.

Step 2: Designing Interactive Dashboards

Once data is prepared, StyleBI's drag-and-drop designer enables the creation of tailored dashboards. For a protective clothing manufacturer, key dashboards might include:

- Production Efficiency Dashboard:

-

Visuals: Line charts for throughput over time, bar charts for yield rate by production line, and gauges for cycle time.

-

Use Case: Monitor real-time production performance to identify bottlenecks. For example, a sudden drop in yield rate could trigger an alert for immediate investigation.

-

Interactivity: Filters for specific product lines or time periods, allowing managers to drill down into underperforming segments.

-

- Quality Control Dashboard:

-

Visuals: Heatmaps for defect density across product types, pie charts for defect types (e.g., stitching errors, material flaws), and tables for compliance status.

-

Use Case: Ensure adherence to safety standards (e.g., OSHA or ISO certifications). Data scientists can embed conditional formatting to highlight non-compliant batches.

-

Interactivity: Brushing capabilities to explore correlations between defect types and production conditions (e.g., machine settings).

-

- Supply Chain Dashboard:

- Visuals: Geographic maps for supplier locations, stacked bar charts for inventory turns, and trend lines for delivery times.

- Use Case: Optimize procurement by identifying reliable suppliers and predicting stock shortages.

- Interactivity: Dynamic filters for supplier performance metrics, enabling scenario analysis.

StyleBI's multi-dimensional charting allows data scientists to create complex visualizations, such as 3D scatter plots to analyze the relationship between cycle time, defect density, and material costs. The platform's self-service features ensure that business users can personalize these dashboards without coding expertise.

Step 3: Advanced Analytics and Predictive Insights

Beyond monitoring, StyleBI supports predictive analytics, a game-changer for proactive decision-making. Data scientists can leverage the platform's machine learning capabilities to forecast trends and mitigate risks. For example:

-

Demand Forecasting: Using historical sales data and external factors (e.g., seasonal trends or regulatory changes), a time-series model can predict future demand for specific protective clothing types. StyleBI's integration with Spark/Hadoop enables scalable processing for large datasets.

-

Defect Prediction: A classification model can identify production conditions likely to result in defects, enabling preemptive adjustments. Data scientists can implement this using Java expressions or external Python scripts integrated via StyleBI's API.

-

Supply Chain Optimization: Clustering algorithms can group suppliers by performance metrics, guiding procurement strategies.

StyleBI's scheduling feature allows these models to run on a timetable, delivering automated reports to stakeholders. For instance, a weekly defect prediction report can be emailed to quality control managers, complete with visualizations.

Step 4: Deployment and Scalability

StyleBI's Java-based architecture supports both on-premise and cloud deployments, making it adaptable to a manufacturer's IT infrastructure. For global operations, the platform's multi-tenant hosting and single sign-on capabilities ensure secure access across regions.

To scale, data scientists can leverage StyleBI's microservices architecture to embed dashboards into existing enterprise applications, such as an ERP portal. The platform's OEM-friendly features, like white-labeling, allow manufacturers to brand dashboards for internal or client-facing use.

Case Study

Consider a mid-sized protective clothing manufacturer, SafeWear Inc., with operations in the U.S. and Asia. SafeWear faces challenges with inconsistent defect rates and supply chain delays. Using StyleBI, their data science team implements the following:

-

Data Integration: Combines ERP data (SAP), quality control logs (CSV files), and supplier performance data (Salesforce) into a unified data block.

-

Dashboards:

-

A production dashboard tracks yield rate and cycle time, revealing that a specific machine is underperforming.

-

A quality dashboard identifies a correlation between high defect rates and a particular fabric supplier.

-

A supply chain dashboard highlights delays from an Asian supplier, prompting a switch to a local alternative.

-

- Predictive Analytics: A random forest model predicts defect risks based on machine settings, reducing defects by 15% after recalibration.

- Automation: Weekly reports are scheduled for delivery to plant managers, improving response times to issues.

Within three months, SafeWear reduces defect rates by 20%, improves throughput by 10%, and cuts supply chain costs by 12%, demonstrating StyleBI's impact.

Challenges and Considerations

While StyleBI is powerful, data scientists should be aware of potential challenges:

-

Learning Curve: While the drag-and-drop interface is intuitive, advanced features like Java expressions require coding expertise.

-

Customization Limits: Some users report less flexibility in report customization compared to competitors like Tableau.

-

Data Quality: The effectiveness of dashboards depends on clean, consistent data, necessitating robust preprocessing pipelines.

To mitigate these, data scientists should invest in training, leverage StyleBI's online tutorials, and ensure data governance protocols are in place.