KPIs and Analytics for a Calciferol Manufacturer

This article explores the KPIs and analytics most relevant to a calciferol manufacturer, providing insight into how such organizations optimize performance across their value chain—from raw material procurement to final product delivery.

1. Production KPIs: Tracking Yield, Purity, and Efficiency

Calciferol manufacturing typically involves either chemical synthesis or extraction and crystallization from biological sources like lanolin or fish liver oil. Given the complexity of these processes, manufacturers track several production-specific KPIs:

A. Batch Yield Percentage

This KPI measures the actual output from a production batch against the theoretical maximum. High batch yields indicate well-optimized synthesis steps, proper environmental conditions, and minimal waste.

Formula: (Actual Output / Theoretical Output) x 100

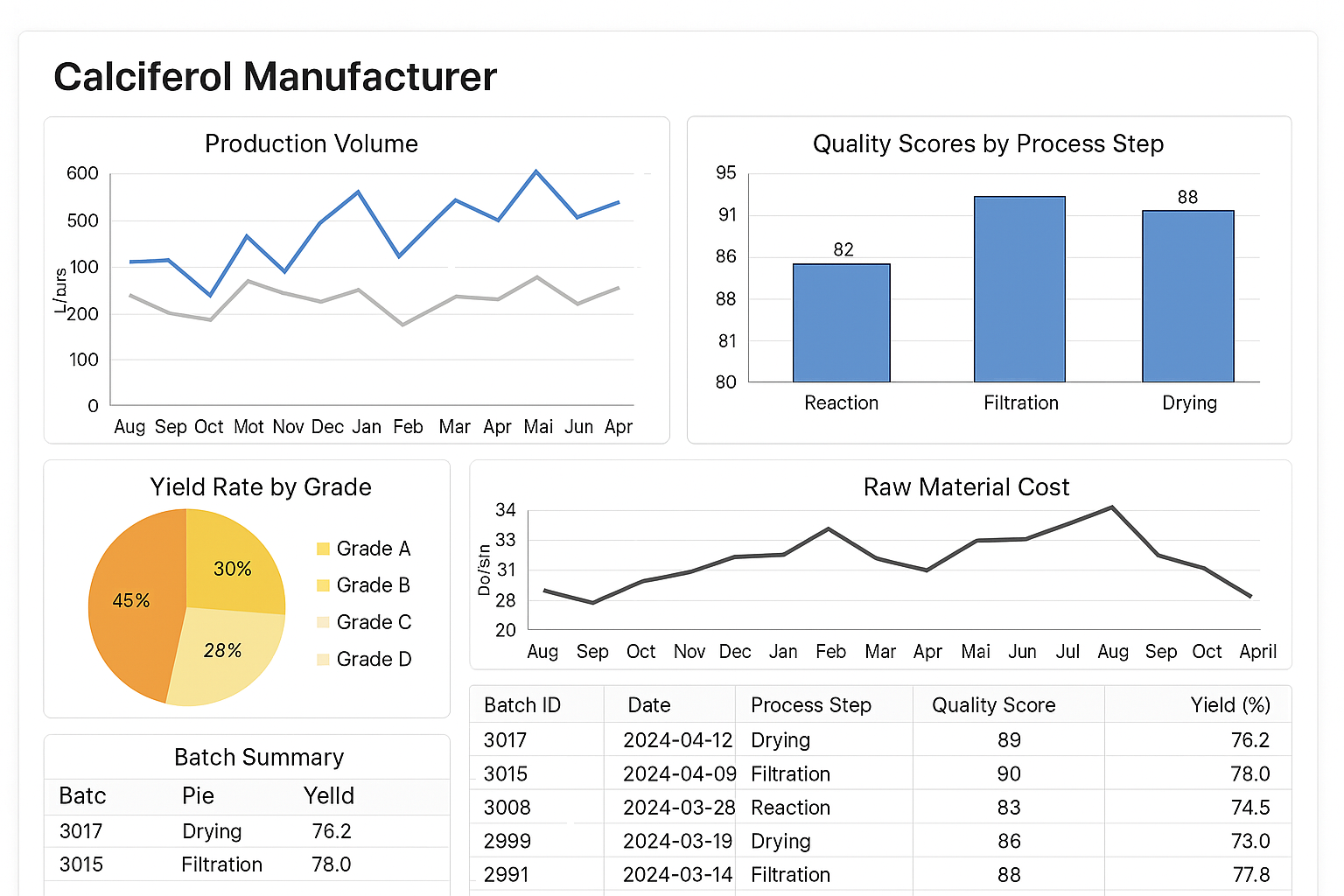

Analytic tools track batch-to-batch variability, enabling root cause analysis in cases of underperformance. Yield anomalies can point to issues with solvents, temperature control, or raw material inconsistencies.

B. Purity Levels

Purity is critical for pharmaceutical-grade calciferol. Labs perform HPLC (High-Performance Liquid Chromatography) or GC-MS (Gas Chromatography–Mass Spectrometry) tests, and the results are tracked over time.

Analytics platforms consolidate these data points, enabling statistical process control (SPC). Patterns can uncover degradation trends or contamination risks, prompting preventive maintenance or supplier reassessment.

C. Cycle Time per Batch

This KPI measures the total time taken from raw material input to finished calciferol output. By reducing cycle times, manufacturers improve throughput and reduce holding costs.

Analytics Application: Real-time dashboards show average batch cycle time, flagging process bottlenecks. Drill-down analytics help identify whether filtration, drying, or crystallization stages are causing delays.

2. Quality KPIs: Ensuring Compliance and Safety

Given that calciferol is consumed as a dietary or pharmaceutical ingredient, quality assurance is non-negotiable. Several KPIs serve this domain:

A. Deviation Rate

Tracks the number of times a production process strays from validated conditions (e.g., temperature excursions or pH variations).

Analytics Application: Deviation logs can be classified by severity and frequency, with predictive models suggesting where SOPs (standard operating procedures) need revision.

B. CAPA Effectiveness Rate (Corrective and Preventive Actions)

After a deviation or non-conformance, CAPAs are issued. The effectiveness rate shows how often the first corrective attempt successfully resolves the issue.

This KPI ties into compliance audits. Data visualization tools highlight which production lines, shifts, or operators are most often involved in ineffective CAPAs.

C. Product Recall Rate

Though ideally zero, tracking recalls over time provides visibility into systemic risks. Root cause analytics link recalls back to upstream causes—improper material handling, poor labeling, or inadequate stability testing.

3. Supply Chain KPIs: Maintaining Flow and Transparency

Calciferol supply chains are sensitive to upstream material availability and downstream demand fluctuations, especially with seasonal surges in vitamin D supplement use. Key supply chain KPIs include:

A. Supplier On-Time Delivery Rate

For biologically derived calciferol, raw materials like lanolin must arrive on schedule. Late deliveries can halt production or force inventory hoarding.

Analytics Application: Heatmaps and trendlines highlight underperforming suppliers. Integrating this data with ERP systems enables proactive reorder triggers and alternative sourcing strategies.

B. Inventory Turnover Ratio

This KPI measures how often inventory is sold and replaced over a given period. Low turnover suggests overproduction or misaligned demand forecasts.

Formula: Cost of Goods Sold / Average Inventory

Analytics can segment this data by calciferol grade (D2 vs D3), market (pharma vs food), or packaging format (bulk powder vs capsule). This granularity helps production planners optimize batch sizes and reduce warehousing costs.

C. Lead Time Variability

High variability here increases the risk of production delays. Analytics platforms use historical data and statistical modeling to simulate best-case and worst-case replenishment scenarios.

4. Regulatory Compliance KPIs

Pharmaceutical and nutraceutical manufacturers must meet rigorous documentation standards. For calciferol manufacturers exporting to multiple countries, compliance KPIs are essential:

A. Audit Readiness Score

Based on document completeness, data integrity, and SOP adherence. Dashboards consolidate GMP audit logs, CAPA timelines, and training records to produce a composite readiness score.

B. Documentation Error Rate

Measures how often batch records, lab reports, or regulatory filings contain errors. High rates suggest poor training or over-reliance on manual data entry.

Analytics Application: NLP (natural language processing) tools can flag missing entries or inconsistent terminology, reducing the risk of non-compliance penalties.

5. Customer and Market Analytics

Calciferol demand is influenced by seasonality, health trends, and geographic regulations. Manufacturers monitor KPIs that gauge responsiveness to market signals.

A. Forecast Accuracy

This KPI compares projected demand versus actual sales. Misalignment can result in stockouts or overproduction.

Analytics Application: Machine learning models that incorporate weather patterns (e.g., winter sunlight scarcity), demographic data, and healthcare trends improve forecasting precision.

B. Customer Complaint Rate

Monitors complaints per million units shipped. Common complaints may include packaging damage, odor, or capsule discoloration.

Analytics Application: Sentiment analysis from customer service records or social media mentions can add qualitative context, allowing companies to act before a minor complaint becomes a brand liability.

6. Financial and Operational KPIs

A vitamin D manufacturer must stay financially viable while navigating volatile input costs (like lanolin or synthetic precursors), energy prices, and R&D expenses. Financial KPIs blend accounting data with operational inputs:

A. Cost per Gram of Calciferol Produced

This KPI considers raw materials, labor, utilities, and waste disposal. It helps determine profitability per product line or batch.

Analytics Application: Comparative dashboards show how cost per gram varies by shift, location, or supplier, guiding strategic investment or cost containment decisions.

B. Overall Equipment Effectiveness (OEE)

OEE combines availability, performance, and quality into a single efficiency metric. In calciferol manufacturing, maintaining sterile conditions and temperature control means even slight inefficiencies can escalate into major losses.

Formula: OEE = Availability x Performance x Quality

Visualization tools help spot underperforming machines or identify scheduling conflicts causing downtime.

C. Return on R&D Investment

As formulations evolve (e.g., vegan-friendly D3 or nanoemulsified variants), this KPI helps manufacturers decide which innovations are worth scaling.

7. Environmental and Sustainability KPIs

Environmental impact is increasingly part of pharmaceutical ESG (Environmental, Social, and Governance) reporting. Sustainability KPIs for calciferol producers include:

A. Energy Usage per Batch

Tracks kWh used in drying, filtration, and packaging phases. High-energy processes may be candidates for heat recovery or alternate sourcing.

B. Solvent Recovery Rate

Calciferol synthesis involves solvents that should be recycled where possible. This KPI measures the percent recovered versus disposed of.

Analytics Application: Trend analysis shows whether recovery rates are improving post-equipment upgrades or after switching to greener solvent systems.

C. Carbon Footprint per Kilogram

Manufacturers aiming to meet carbon reduction targets track emissions by product line and production method (e.g., chemical synthesis vs biological extraction).