BI Implementation Analysis

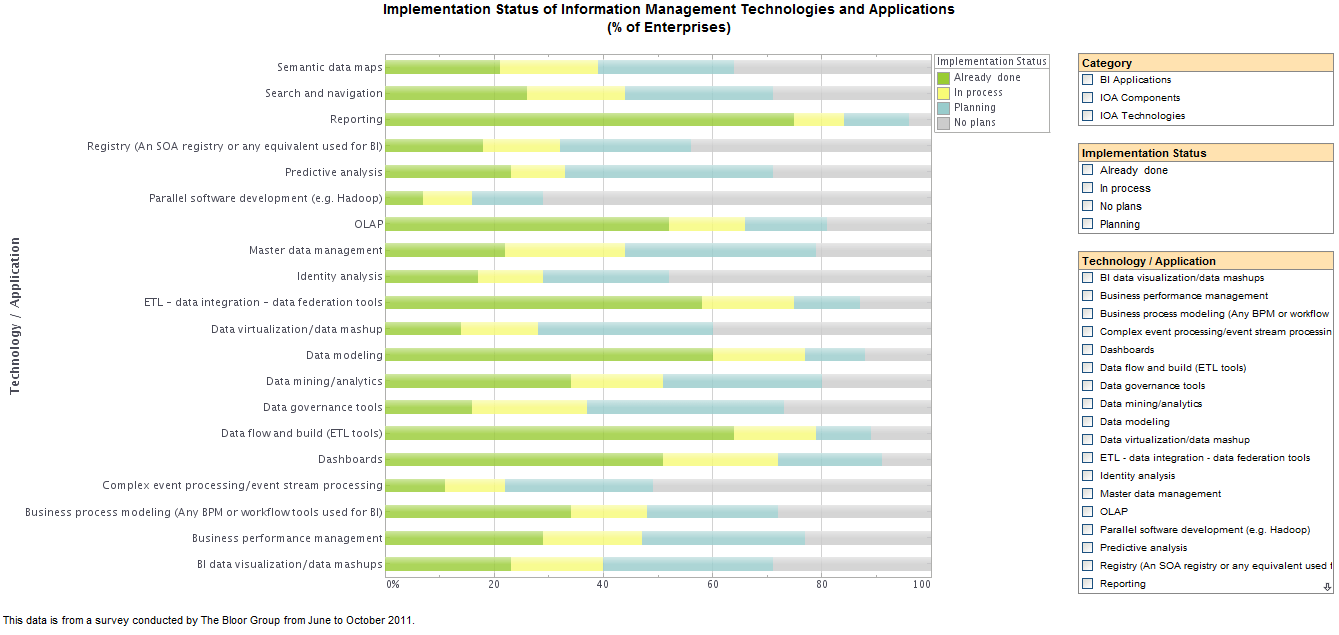

The BI Implementation Analysis below is an example of an interactive web-based analytical dashboard built using InetSoft's intuitive software. A leader in dashboard, reporting, and data mashup solutions, InetSoft provides users with an easy-to-use software with multiple features and tools that enhances business operations.

By creating a visualization that allows users to mashup two different data sets, the chart below makes filtering and analyzing business intelligence implementation easy to do. With an easy-to-use point and click environment, along with a full set of customizable features, users can simplify their workload by drilling down into a specific set of technology applications, percentage of enterprises, category, and/or even implementation status.

InetSoft's visualization software combines ease of use with detailed tools and features to help users in day-to-day operations, as well as help them keep track of and achieve long term goals and objectives.

Capabilities of the InetSoft's BI Implementation Analysis Dashboard:

- Monitor, explore, and analyze by filtering and sorting desired information

- Easy to use, modify, and create charts and visuals

- Leverage user-driven data mashup

- Upload and sift through multi-dimensional data to spot trends and aberrations

- Slice and dice data with simple point-and-click method

- Share visual analysis with others

Transforming Analytics in the Fructose Refinement Industry with StyleBI

The fructose refinement industry occupies a niche space within global food and biochemical markets. Unlike large-scale sugar refineries or starch processors, fructose refiners specialize in isolating and purifying high-fructose solutions for use in pharmaceuticals, nutraceuticals, and specialty foods. These companies operate with tight margins, high compliance requirements, and supply chains sensitive to commodity price swings and seasonal agricultural yields. For one such company, the lack of a robust analytics platform made data-driven decision-making difficult, leading to inefficiencies in forecasting, production optimization, and customer reporting.

When the leadership team decided to upgrade its analytical capabilities, they selected StyleBI as their solution of choice. This decision was not made lightly; IT managers, plant engineers, finance leads, and compliance officers were all stakeholders in the process. The result was a multi-year transformation that replaced legacy spreadsheet-based reporting with a modern, scalable business intelligence environment tailored to the unique demands of biochemical manufacturing.

Challenges in Fructose Refinement Data Management

Before StyleBI, the refiner relied on a patchwork of data tools. Production metrics were captured by SCADA systems, inventory was tracked in ERP software, sales data lived in CRM platforms, and quality assurance results were housed in laboratory information systems. Each system had its own reporting module, but none could integrate seamlessly. As a result, decision-makers often relied on manually merged spreadsheets, a process that consumed valuable analyst time and introduced errors.

For example, forecasting fructose yields from corn input required pulling data from procurement, plant throughput, and lab test results. Finance then needed to adjust for contract pricing, hedging positions, and transportation costs. This level of manual integration often delayed insights by weeks, reducing the company’s ability to respond quickly to shifting commodity prices or unexpected quality issues. Moreover, regulators and clients demanded increasingly transparent reporting, which the patchwork system struggled to provide in a timely fashion.

Why StyleBI Was Chosen

The IT leadership evaluated several BI platforms, from well-known names like Tableau and Power BI to lesser-known but specialized vendors. StyleBI stood out for three main reasons:

- Serverless and Scalable: StyleBI’s architecture offered flexibility for a midsized refiner without requiring large capital investments in infrastructure. The company’s IT team could scale up analytics capacity during harvest season, when data volumes surged, and scale down afterward.

- Data Mashup Capabilities: The tool excelled at connecting disparate systems—ERP, SCADA, CRM, and lab databases—into a single analytical environment without requiring extensive custom ETL coding. This was crucial for a company with heterogeneous data sources.

- Licensing and Cost Structure: Compared to enterprise-oriented solutions, StyleBI’s licensing model was more favorable to a firm with under 1,000 employees. Instead of per-seat fees spiraling out of control, the company could align costs with usage patterns.

The final deciding factor was StyleBI’s ability to create secure, shareable dashboards tailored to specific stakeholders. Plant operators needed real-time throughput metrics, while finance leaders needed consolidated margin analyses, and compliance teams required audit-ready reporting. StyleBI promised to deliver all three within a single platform.

Implementation Journey

The implementation was staged over twelve months. The IT department partnered with StyleBI consultants but retained control of key integration processes to ensure knowledge transfer. The first phase involved connecting core databases: ERP for inventory and procurement, SCADA for plant operations, and the LIMS for lab results. Once these sources were harmonized, StyleBI’s mashup engine enabled analysts to create cross-functional datasets that had never before been possible.

In phase two, custom dashboards were built. A production dashboard displayed hourly throughput, energy consumption, and chemical yield rates. A financial dashboard combined sales contracts with commodity market data to forecast profitability in near-real time. A compliance dashboard tracked deviations in purity and safety metrics, automatically flagging potential issues for review. For the first time, managers at all levels could view the same version of the truth, eliminating the endless reconciliations that had plagued earlier reporting efforts.

The final phase was cultural adoption. The company invested in training sessions, empowering non-technical staff to create their own ad hoc reports. Instead of relying on IT or finance analysts for every data request, plant managers could explore yield variations on their own, while sales staff could drill into customer-specific purchasing trends. This democratization of data helped build momentum for further adoption.

Resource and Overhead Savings

Implementing StyleBI delivered measurable resource savings almost immediately. Previously, three full-time analysts dedicated much of their time to manually merging data and producing weekly reports. After the new dashboards went live, those tasks were automated, freeing the analysts to focus on predictive modeling and scenario planning. The IT department also reported reduced overhead, since StyleBI’s serverless design meant fewer resources dedicated to maintaining reporting infrastructure.

From a licensing perspective, StyleBI’s usage-based model saved the company an estimated 40% compared to what it would have spent with larger BI vendors. More importantly, scaling licenses up or down during harvest season aligned costs directly with business needs, avoiding the waste inherent in static, enterprise-wide licenses.

Support and Maintenance Benefits

Support and maintenance also saw significant improvements. Previously, each data silo had its own vendor, meaning IT had to coordinate with multiple providers whenever integration issues arose. With StyleBI, a single support channel covered the analytics layer, while the built-in connectors reduced reliance on brittle custom scripts. IT staff estimated a 30% reduction in troubleshooting time and a 50% faster turnaround on change requests from business units.

Another unexpected benefit was compliance readiness. Because StyleBI could automatically log transformations and maintain a clear data lineage, the company found it easier to generate audit trails for regulators. What once required days of manual reconstruction now took minutes, reducing both cost and stress during inspections.

End-User Satisfaction

While the technical and financial gains were substantial, management emphasized that the greatest benefit was end-user satisfaction. Plant operators appreciated real-time visibility into efficiency metrics, allowing them to make small adjustments that collectively improved yields. Sales leaders could track customer demand patterns more precisely, improving contract negotiations. Compliance teams reduced reporting bottlenecks, giving them more time to focus on proactive risk management instead of reactive firefighting.

The executive team also found value in consolidated dashboards. Instead of wading through lengthy reports, they could view visualizations summarizing financial health, production performance, and compliance status on a single screen. This level of clarity improved strategic planning, especially when navigating volatile commodity markets.

Lessons Learned

The fructose refiner’s experience highlights several lessons that apply to other niche industries considering a BI upgrade:

- Start with Core Data Sources: Harmonizing ERP, SCADA, and LIMS systems created a foundation for more advanced analytics.

- Invest in Training: End-user adoption is as important as technical integration. Empowering non-technical staff reduced reliance on analysts and built a data-driven culture.

- Align Licensing with Business Cycles: Seasonal businesses benefit from flexible, usage-based licensing models, avoiding overpayment during low-volume periods.

- Think Compliance Early: Features like data lineage tracking are not just conveniences; they can drastically reduce the cost of regulatory audits.

Looking Forward

With StyleBI firmly embedded in its operations, the refiner is already exploring next steps. Predictive analytics for crop yield forecasting, integration with external commodity price feeds, and advanced scenario modeling for energy usage are all on the roadmap. The company also plans to extend dashboards to key customers, providing greater transparency and strengthening long-term relationships.

For an industry as specialized as fructose refinement, the shift from spreadsheet-driven processes to a unified BI environment represents a profound cultural and operational transformation. By selecting StyleBI, the company not only reduced costs and resource overhead but also unlocked new levels of insight that position it competitively in a volatile market. For IT professionals, the story underscores the power of choosing a solution tailored not just to scale but also to the unique rhythms of a specialized industry.