A Visual Complement to Microsoft SQL Server Analysis Services

Visual intelligence might be the most important aspect of powerful BI programs like Microsoft SQL Server Analysis Services. When communicating with a team through data, having a comprehensive utility like Microsoft SQL Server Analysis Services might only be the starting point.

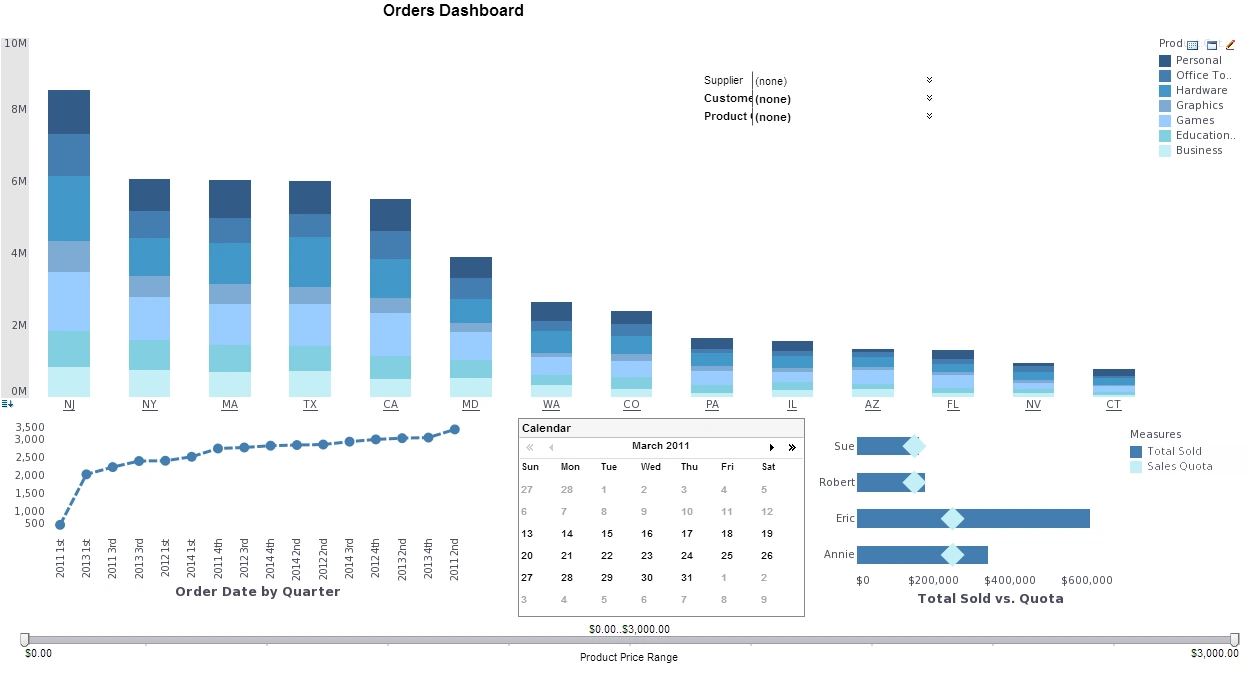

When implementing a complementary data visualizer (a dashboard and report generator) with an SaSS database, the result is the catalyzation of incisive decisions made radically fast. That's the advantage of InetSoft's BI software suite, StyleBI™.

But how does it do this? Style suite applications can query Microsoft SSAS cubes through MDX for easy creation of dashboard reports and data mashups. In fact, StyleBI is not limited to MS SQL or SSaS. Its robust data mashup engine is versatile, with the ability to pull data from many disparate sources for reporting and analysis. In addition to MSSAS, StyleBI can integrate with other databases, such as Hyperion Essbase, Oracle OLAP, and SAP NetWeaver.

Accessible Visual Reporting

Microsoft SQL Server Analysis Services is a comprehensive BI reporting tool. It is, however, a tech-heavy program. It lacks visual simplicity so rendering an analysis can become cumbersome, especially for non-IT users.

With StyleBI on top of your OLAP Server, any user can easily make eye-popping charts, graphs, and dashboards that clearly communicate business conditions and needs. The simple, java-based application can be learned easily regardless of IT background.

Since StyleBI is a web based application, it can be accessed with any web browser. This allows for greater access and collaboration than using Microsoft SQL alone. Taking advantage of increasingly capable smartphone technology and the rapidly expanding reach of html5, StyleBI is mobile capable, making even enormous databases pants-pocket portable.

Gallium Recovery and Refinement Company Transforms Dashboard Reporting with InetSoft

In the specialized world of critical materials, gallium recovery and refinement stands out as a niche yet essential industry. Gallium is not mined directly; instead, it is obtained as a byproduct of processing bauxite for aluminum and zinc ores for smelting. Because gallium plays a vital role in semiconductors, LEDs, solar panels, and other advanced technologies, refiners must track complex datasets spanning yield percentages, chemical purity, supply chain fluctuations, and customer demand. In such an environment, data is more than just operational detail—it is a competitive weapon.

For years, one gallium recovery and refinement firm relied on Microsoft SQL Server Analysis Services (SSAS) to provide analytical capabilities. While powerful for OLAP modeling, SSAS came with challenges: heavy infrastructure overhead, rigid cube structures, costly licensing, and limited dashboard flexibility for non-technical users. As global competition and compliance pressures mounted, the company’s leadership recognized the need for a more agile, cost-effective solution. After extensive evaluation, the firm migrated to InetSoft’s dashboard reporting tool, StyleBI, which provided a leaner architecture, better integration flexibility, and superior end-user satisfaction.

Challenges with SQL Server Analysis Services

SQL Server Analysis Services had served the company well in its early years. It enabled multidimensional cubes for analyzing production metrics, allowed integration with SQL Server databases, and supported corporate reporting. However, as operations grew more complex, shortcomings became increasingly apparent.

- High Licensing Costs: Maintaining SQL Server Enterprise Edition for SSAS meant escalating licensing fees. Even as some users only required lightweight dashboards, the licensing structure forced the company to pay enterprise-wide costs.

- Rigid Cube Models: Building OLAP cubes required significant IT expertise, and changes to data models could take weeks. In a fast-moving industry where gallium demand is influenced by semiconductor cycles, this rigidity was unacceptable.

- Infrastructure Overhead: SSAS required substantial on-premise infrastructure. The IT department had to maintain servers, manage cube processing, and ensure availability. Scaling up during peak reporting cycles was costly and cumbersome.

- Limited Dashboard Accessibility: Non-technical staff struggled with the tools available for viewing and interacting with SSAS cubes. While analysts could generate reports, managers and plant operators often relied on static exports rather than interactive dashboards.

These challenges accumulated into delays, higher costs, and reduced decision-making agility. By 2023, the company decided to evaluate alternatives that could offer real-time dashboarding, reduced overhead, and easier adoption across departments.

Why InetSoft Was Selected

The IT and operations leadership evaluated several business intelligence solutions. InetSoft emerged as the preferred choice for multiple reasons:

- Lightweight Architecture: InetSoft’s serverless and cloud-flexible design eliminated the need for heavy cube processing and dedicated infrastructure, reducing both IT burden and cost.

- Flexible Data Mashups: Instead of rigid cube structures, InetSoft allowed blending data from multiple sources—ERP systems, SCADA equipment data, and laboratory results—without extensive ETL pipelines.

- Cost-Effective Licensing: InetSoft’s usage-based licensing aligned with actual needs. The company could scale licenses according to active users and reporting cycles, rather than paying across the entire enterprise.

- User-Friendly Dashboards: InetSoft’s drag-and-drop interface empowered non-technical staff to build and explore dashboards. Plant managers, engineers, and finance leaders could access insights without relying on IT intermediaries.

In addition, InetSoft’s focus on KPI-driven dashboards aligned with the company’s desire to monitor key metrics such as gallium recovery rate, energy usage per kilogram, and purity levels in near real time.

Implementation Process

The transition took place over a 10-month period, with careful attention to continuity and compliance. The implementation was divided into three major phases:

Phase 1: Core Integration The IT team began by connecting InetSoft to existing SQL Server databases, ERP systems, and laboratory information systems. Using InetSoft’s mashup engine, data could be unified without restructuring the original schemas. This step eliminated the need for OLAP cube design, saving weeks of IT development time.

Phase 2: Dashboard Creation Next, role-specific dashboards were created. Plant operators received dashboards showing hourly recovery yields, energy efficiency, and process anomalies. Finance leaders were given profitability dashboards linking gallium output with global pricing trends. Compliance teams used dashboards that tracked chemical purity deviations and automatically logged data lineage for audit purposes.

Phase 3: End-User Training InetSoft conducted workshops to empower non-technical users to interact with dashboards. Instead of waiting for IT to generate cube reports, managers could perform ad hoc analysis on their own. This cultural shift toward self-service analytics dramatically improved adoption and satisfaction.

Licensing and Resource Savings

One of the most immediate financial benefits came from licensing changes. SQL Server Analysis Services required enterprise licensing tiers, even for departments that only needed light reporting. By moving to InetSoft, the company shifted to a usage-based model. As a result, licensing costs dropped by nearly 40%, with savings reinvested in R&D initiatives.

In terms of resources, the IT department reported significant efficiency gains. Cube building, which previously consumed two analysts’ time for maintenance and updates, was eliminated entirely. Instead, analysts now focused on predictive modeling, such as forecasting gallium yield based on ore quality and optimizing refining parameters. Over the course of the first year, the company calculated that 2,500 IT labor hours were redirected to higher-value tasks.

Reduced Overhead and Support Costs

InetSoft’s lightweight deployment model reduced infrastructure overhead substantially. Previously, dedicated servers had to be allocated for cube processing and report distribution. Scaling during end-of-quarter reporting periods required expensive hardware or overtime IT shifts. With InetSoft, the firm leveraged cloud capacity, scaling elastically without permanent infrastructure investments.

Support costs also fell. With SSAS, troubleshooting required coordination between Microsoft support and internal IT, often with slow turnaround. InetSoft provided a single point of contact for support and simplified updates, cutting resolution times in half. The compliance team noted additional savings since automated lineage and logging reduced the effort needed to prepare audit reports.

Management and End-User Satisfaction

Perhaps the most impactful change was improved satisfaction among executives and end-users. The executive dashboard delivered real-time snapshots of production efficiency, market alignment, and compliance risk on a single screen. This level of visibility had been impossible with SSAS, where reports were static and lagged by days or weeks.

Plant operators, previously reliant on delayed cube reports, now had access to live process dashboards. They could see deviations in recovery rates instantly and adjust processes on the fly, improving yield efficiency by an estimated 8% within six months. Finance staff gained more accurate profitability models, while compliance officers enjoyed automated reporting that reduced stress during regulatory inspections.

End-users consistently praised the intuitive design. Instead of navigating cube structures, they could interact with familiar visual dashboards, drill into data, and generate their own insights. The IT team reported a sharp decline in ad hoc report requests, which further reduced backlog and improved overall organizational agility.

Lessons Learned

The company’s experience offers lessons for other niche industries considering a migration from SSAS or other legacy BI platforms:

- Cube-Free Flexibility: For industries with complex, shifting data models, eliminating cube rigidity accelerates insight generation.

- Align Licensing to Needs: Usage-based licensing ensures costs scale appropriately and prevents wasted budget on underutilized seats.

- Empower End-Users: Self-service dashboards democratize analytics, spreading data-driven decision-making across all levels of the organization.

- Plan Training Early: Cultural adoption is as important as technical migration. Equipping non-technical staff builds momentum and reduces resistance.

Future Roadmap

With InetSoft fully deployed, the company is planning additional enhancements. Predictive analytics will be used to forecast gallium output based on ore quality and energy usage, helping to optimize production scheduling. Integration with external commodity pricing feeds will allow finance dashboards to update profitability models in real time. Customer-facing dashboards are also on the roadmap, offering buyers transparency into production schedules and quality metrics, strengthening relationships in a competitive market.